Whirl etching system and method for large area silicon chips

A rotary etching and large-area technology, which is applied in chemical instruments and methods, crystal growth, electrical components, etc., can solve problems such as inconsistent corrosion speed, different flatness of silicon wafers, and inability to fully stir, so as to improve production efficiency and control temperature precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

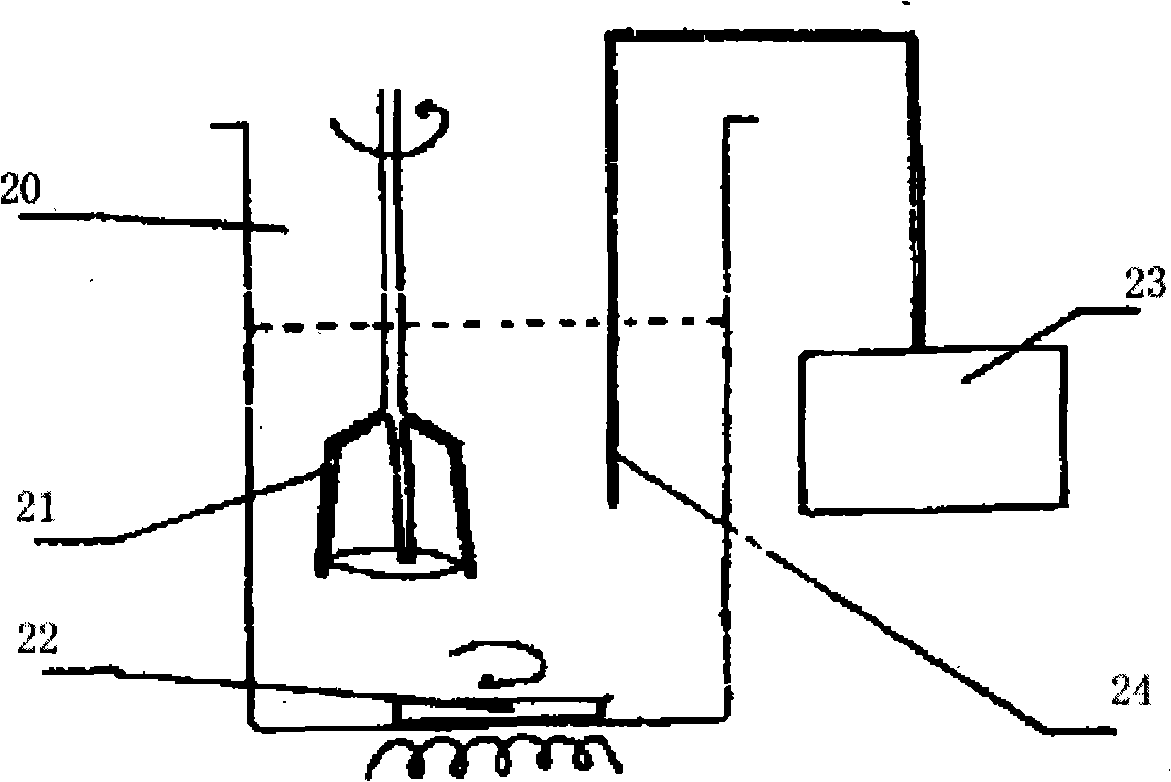

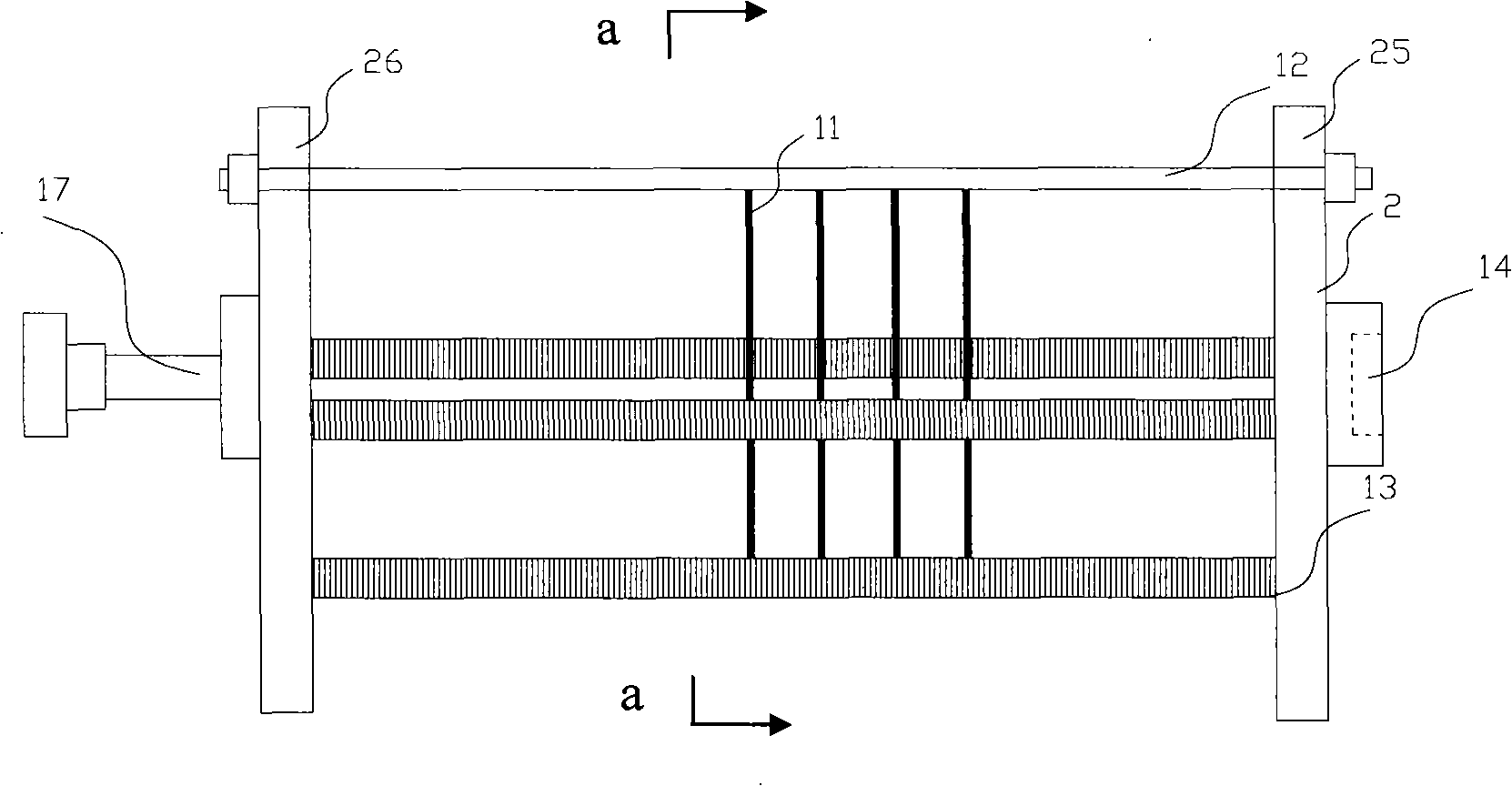

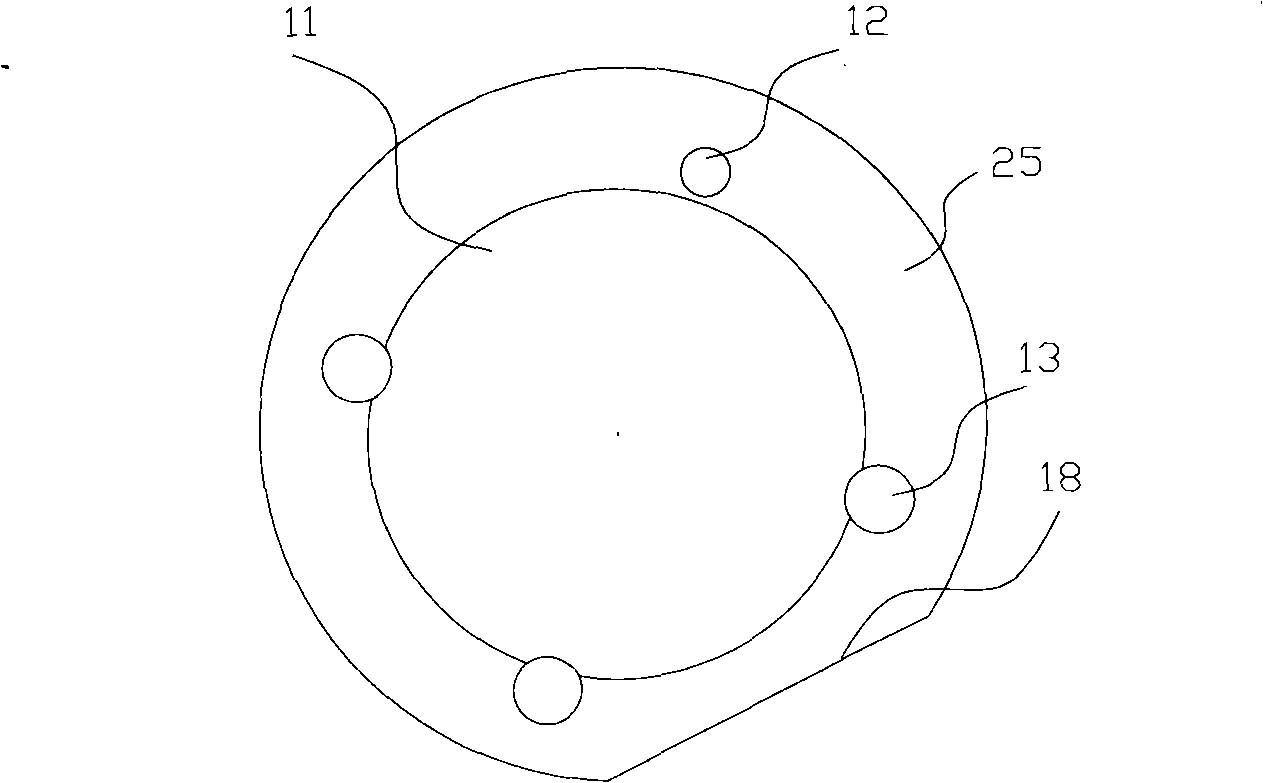

[0032] Figure 2 to Figure 8 It is a schematic diagram of Embodiment 1 of the spin etching system for large-area silicon wafers.

[0033] Silicon wafers with measured and recorded thicknesses were mounted on Figure 2 ~ Figure 4 shown on the rotating corrosion fixture, where, figure 2 Shown is a schematic front view of the rotating corrosion fixture, image 3 Shown is a schematic left view of the cross-section of the fixture along the a-a direction, Figure 4 Shown is the schematic view of the right side view of the clamp after the support bar 12 is removed. Described clamp 2 is made up of four evenly distributed support rods 12,13 and two circular baffles 25,26 connected thereto, and the purpose of platform 18 on the baffle is to facilitate the placement of the clamp, wherein three fixed support rods 13 There are grooves engraved on it to fix the silicon chip. The diameter of the detachable support rod 12 is smaller than that of the other three. When loading the silicon ...

Embodiment 2

[0038] Figure 9 ~ Figure 12It is a schematic diagram of the second embodiment of the spin etching system for large-area silicon wafers.

[0039] Silicon wafers with measured and recorded thicknesses are loaded into Figure 9 The rotary corrosion fixture is shown on 2. Described clamp 2 is made up of four evenly distributed support rods 12,13 and two circular baffles 25,26 connected thereto, and the purpose of platform 18 on the baffle is to facilitate the placement of the clamp, wherein three fixed support rods 13 There are grooves engraved on it to fix the silicon chip. The diameter of the detachable support rod 12 is smaller than that of the other three. When loading the silicon chip, remove it from the groove 16 to leave a space, then put the silicon chip 11 into it, and then install it. The upper detachable support rod 12, which is just in contact with the edge of the silicon wafer 11 to play a position-limiting role; the driven gear 29 is connected with the rotating sh...

Embodiment 3

[0043] Figure 13 is a schematic flow chart of the spin etching method for large-area silicon wafers, Figure 14 ~ Figure 18 It is a schematic diagram of an embodiment of a spin etching method for a large-area silicon wafer.

[0044] Step 201: Refer to Figure 14 As shown, the silicon wafer whose thickness has been measured and recorded is rotated on the corrosion fixture 2. The fixture 2 is made up of four evenly distributed support rods 12, 13 and two circular baffles 25, 26 connected thereto. The purpose of the platform 18 is to facilitate the placement of the clamps. Three of the fixed support rods 13 are engraved with grooves to fix the silicon chip. The diameter of the detachable support rod 12 is smaller than the other three. Then remove the silicon chip 11 to leave a space, and then install the detachable support rod 12, which just comes into contact with the edge of the silicon chip 11 to play a position-limiting role.

[0045] Step 202: Refer to Figure 15 As sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com