BiSbTeSe-based thermoelectric material

A technology of thermoelectric materials and mixing materials, applied in thermoelectric device node lead-out materials, thermoelectric device manufacturing/processing, inorganic chemistry, etc., can solve the problems of high thermal conductivity, material resistivity and thermal conductivity, and affecting material Thermoelectric performance and other issues, to achieve the effect of reducing thermal conductivity, good thermoelectric performance of materials, and improving thermoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] A preparation method of a BiSbTeSe-based thermoelectric material, the preparation method comprising the following steps:

[0035] 1) Powder mixing: take four elemental powders of Bi, Sb, Se, Te and S, Si, P, Ge, Sn, Ce, Li, I, Br, Al, Cu, Ag, Yb, Tm, La, Gd , Dy elemental powder, or one or more mixed powders, put it into a vacuum ball mill tank or a mixer tank, and evacuate to 10 -1 Pa or pass argon, then use a ball mill or mix and mix;

[0036] 2) Alloy smelting: put the above-mentioned mixed powder into the furnace tube of the chemical vapor deposition equipment, and vacuumize to 10 -2 pa, heated to 1000°C-1100°C to melt and vaporize the raw material powder, carry out reaction deposition in the furnace tube, the reaction time is 20h, and naturally cool to room temperature after the reaction to obtain a BiSbTeSeS-based p-type thermoelectric material alloy ingot.

[0037] A preparation method of a BiSbTeSe-based thermoelectric material, the preparation method comprisi...

Embodiment 1

[0045] A BiSbTeSe-based thermoelectric material, the preparation method of the BiSbTeSe-based thermoelectric material is as follows:

[0046] 1) Powder mixing: according to the mole fraction of Bi, Sb, Te, Se and S: 8%, 32%, 54%, 3% and 3%, weigh Bi, Sb, S, Se with a purity of 4N and Te five elemental powders, put into a vacuum ball mill jar, and vacuumize to 10 -1 Pa or pass in argon, then use a ball mill or mix and mix, the speed of the vacuum ball mill tank is 50r / min, and the mixing time is 2h;

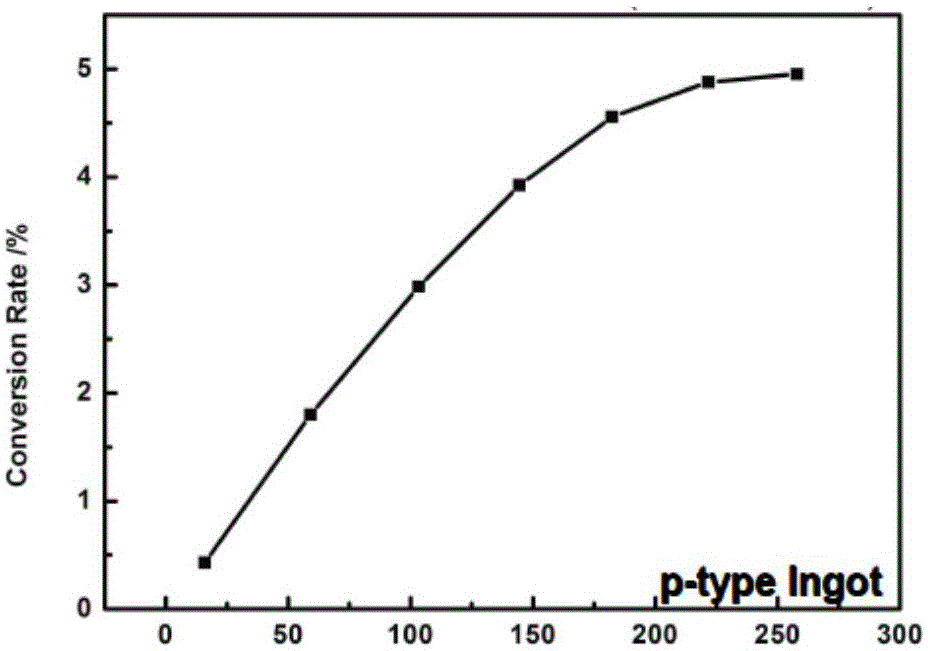

[0047] 2) Alloy smelting: put the above-mentioned mixed powder into the furnace tube of the chemical vapor deposition equipment, and vacuumize to 10 -2 pa, heated to 1000°C-1100°C to melt and vaporize the raw material powder, and carry out reaction deposition in the furnace tube. The reaction time is 20h. After the reaction is completed, it is naturally cooled to room temperature to obtain an alloy ingot of BiSbTeSeS-based p-type thermoelectric material. The BiSbTeSe The general...

Embodiment 2

[0049] A BiSbTeSe-based thermoelectric material, the preparation method of the BiSbTeSe-based thermoelectric material is as follows:

[0050] 1) Powder mixing: according to the mole fraction of Bi, Sb, Te, Se and S: 12%, 28%, 58%, 1.5% and 0.5%, weigh Bi, Sb, S, Se with a purity of 5N and Te five elemental powders, put into a vacuum ball mill jar, and vacuumize to 10 -1 Pa or pass in argon, then use a ball mill or mix and mix, the speed of the vacuum ball mill tank is 50r / min, and the mixing time is 2h;

[0051] 2) Alloy smelting: put the powder into a quartz tube with a diameter of 25mm that has been sealed at one end, vacuumize the quartz tube and melt the seal. First carry out zone smelting for 20 hours, and naturally cool to room temperature to obtain an alloy ingot of BiSbTeSeS-based p-type thermoelectric material. The general formula of the BiSbTeSe-based thermoelectric material is Bi 0.6 Sb 1.4 Te 2.9 Se 0.3 S 0.025 .

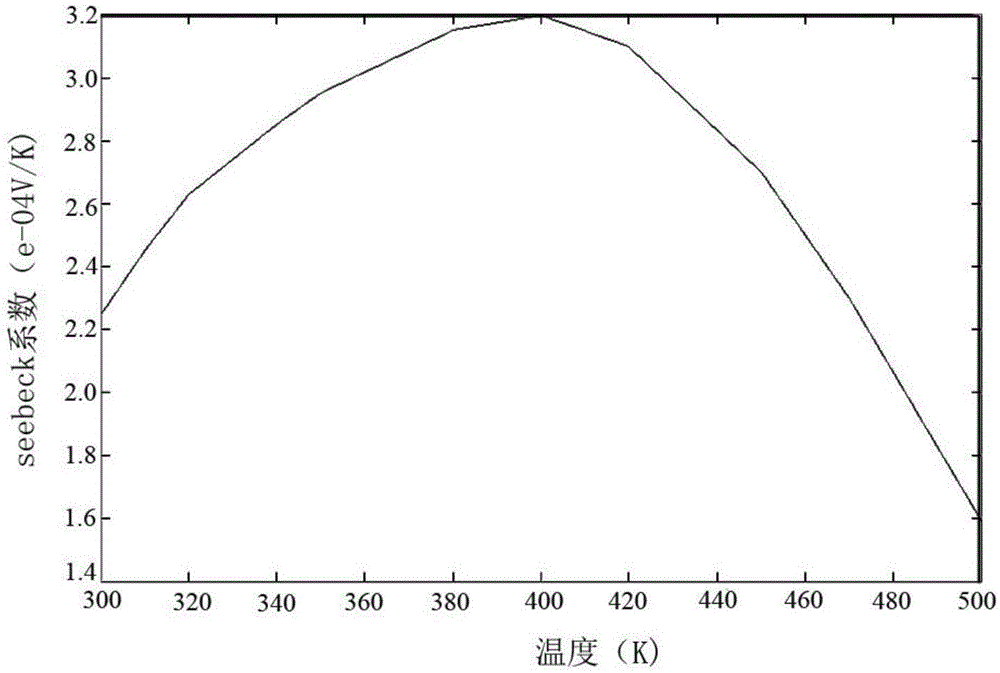

[0052] 1. Thermal conductivity test

[005...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

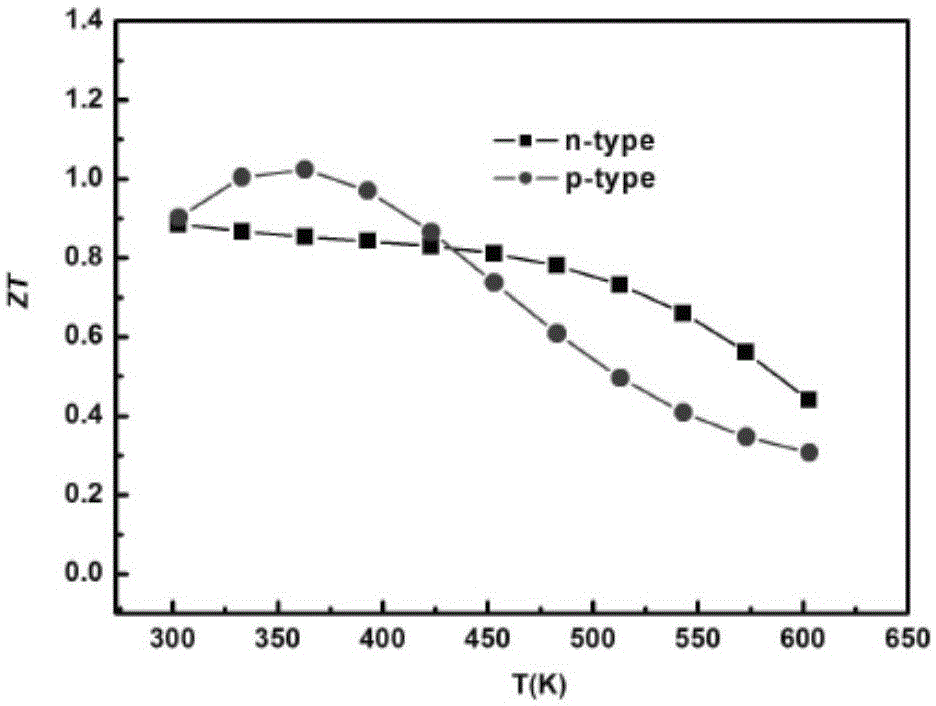

| thermoelectric figure of merit | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com