Dry heating prevention method of liquid heating device and heating device using dry heating prevention method

A heating device and anti-dry-burning technology, applied in the field of liquid heating, can solve the problems of dry-burning power-off time, inability to achieve precise temperature control, and high temperature of the heating body, achieve rapid temperature sensing, avoid excessively high temperature, and Control accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

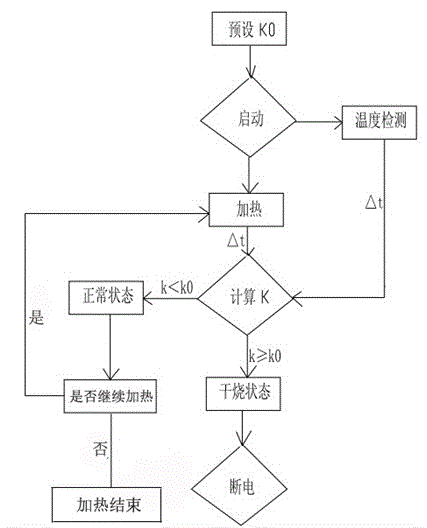

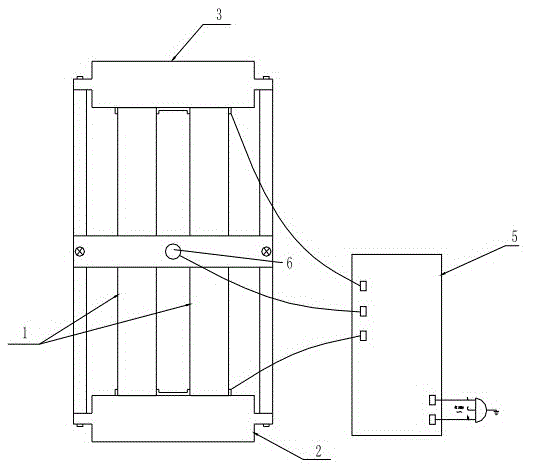

[0020] Such as figure 1 As shown, a method for preventing dry burning of a liquid heating device, the liquid heating device includes a heating element 1, a control unit 5, and a temperature-sensing component 6 for sensing the temperature of the heating element, the heating element 1 and the temperature-sensing component 6 are both connected to The control unit 5 is connected, comprising the following steps:

[0021] A. Start the liquid heating device to heat the liquid;

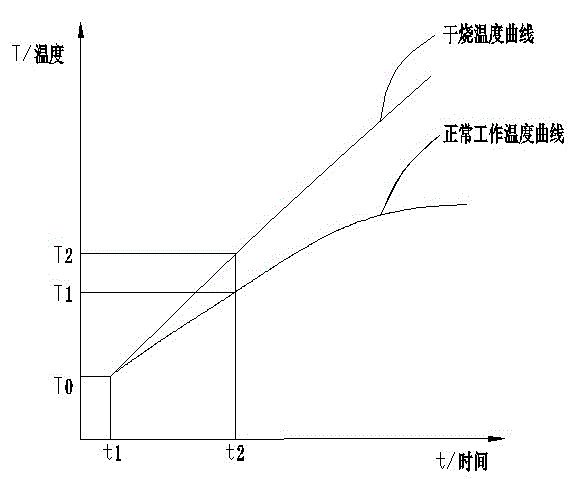

[0022] B. The control unit 5 presets the lowest dry-burning temperature change rate of the heating element 1 to k0, the temperature sensing component 6 detects the temperature T of the heating element 1, the control unit 5 records the heating time t, and the temperature T of the heating element 1 One-to-one correspondence with the heating time t is stored in the control unit 5; the control unit 5 records the change of the heating time as Δt, and the control unit 5 records the temperature change ΔT of the hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com