Electromagnetic heating electric pressure cooker

An electric pressure cooker and electromagnetic technology, applied in cooking utensils, household appliances, applications, etc., can solve the problems of pressure bearing and elastic deformation ability, difficult to control pressure stably, increasing the height of the bottom of the pressure cooker, and the elastic structure occupying a large internal space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

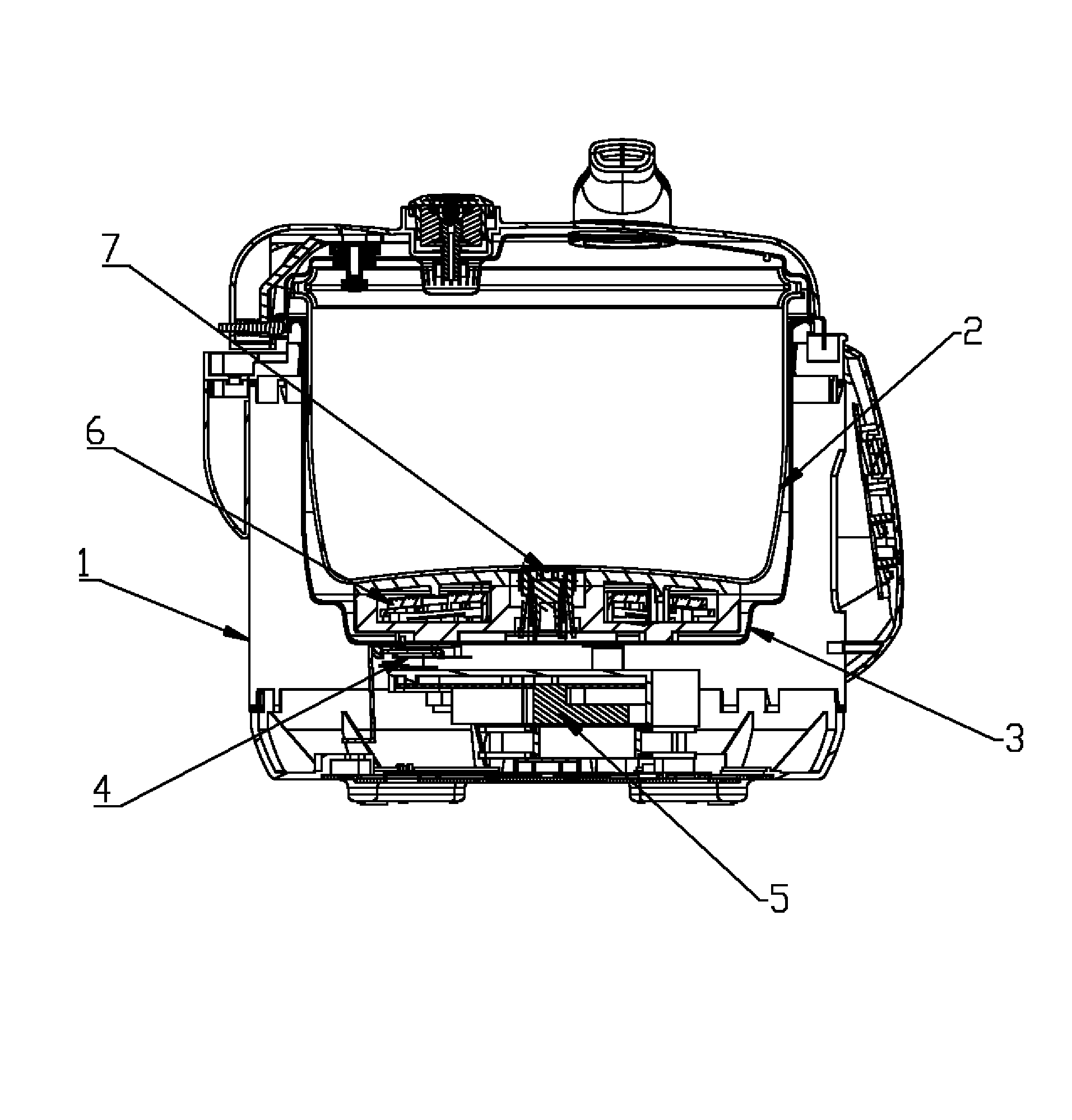

[0053] Embodiment 1 of an electromagnetically heated electric pressure cooker of the present invention is as Figure 1 to Figure 7 As shown, it includes an outer shell 1, an inner pot 2 and an outer pot 3 arranged in the outer shell 1, a pressure switch 4 and a control device 5 are arranged at the bottom of the outer pot 3, and a ring shaped pot is also arranged between the outer pot 3 and the inner pot 2 The heating plate assembly 6 and the sensor assembly 7 are provided. A through hole is opened in the middle of the heating plate assembly 6, and the sensor assembly 7 is installed in the through hole.

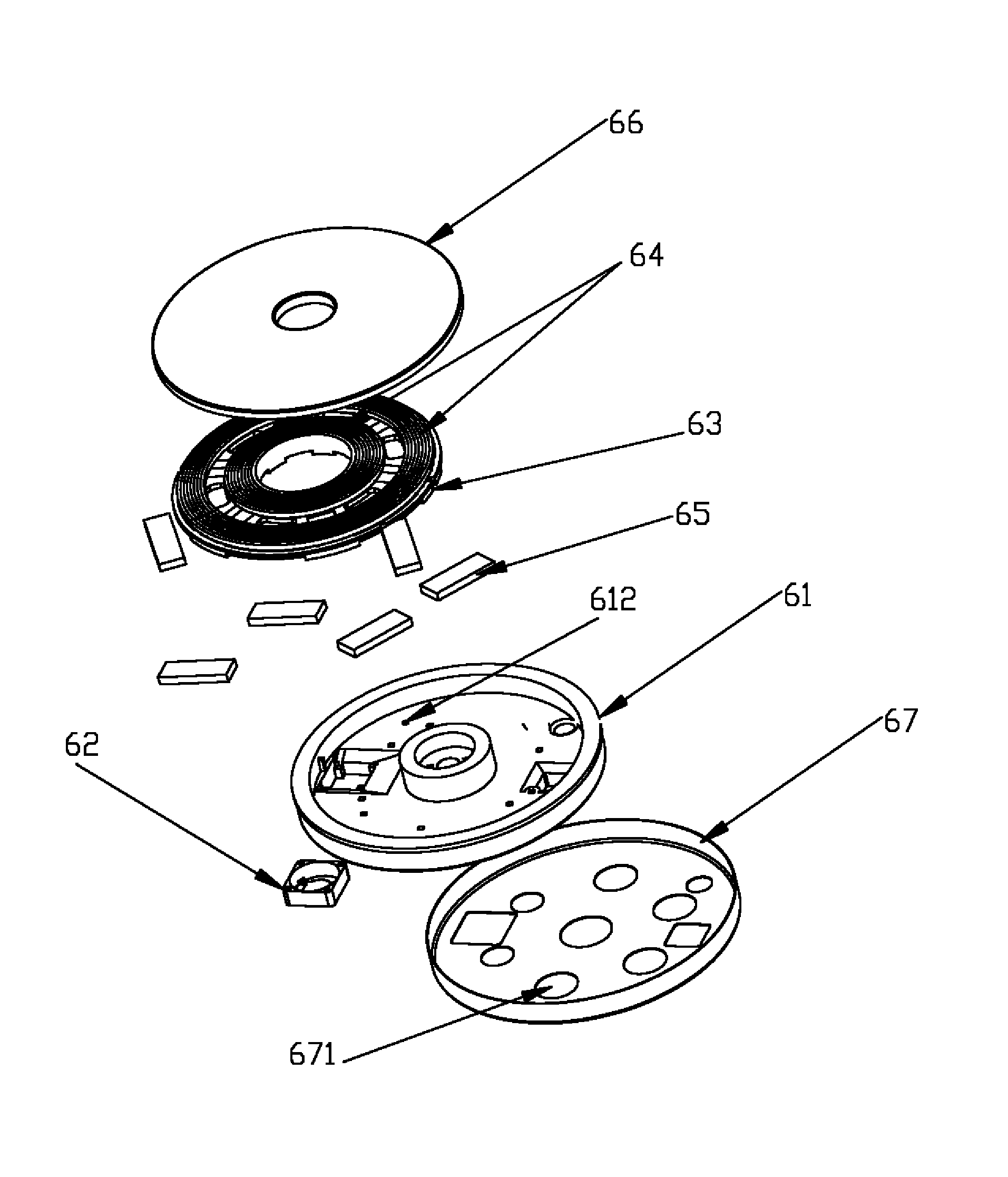

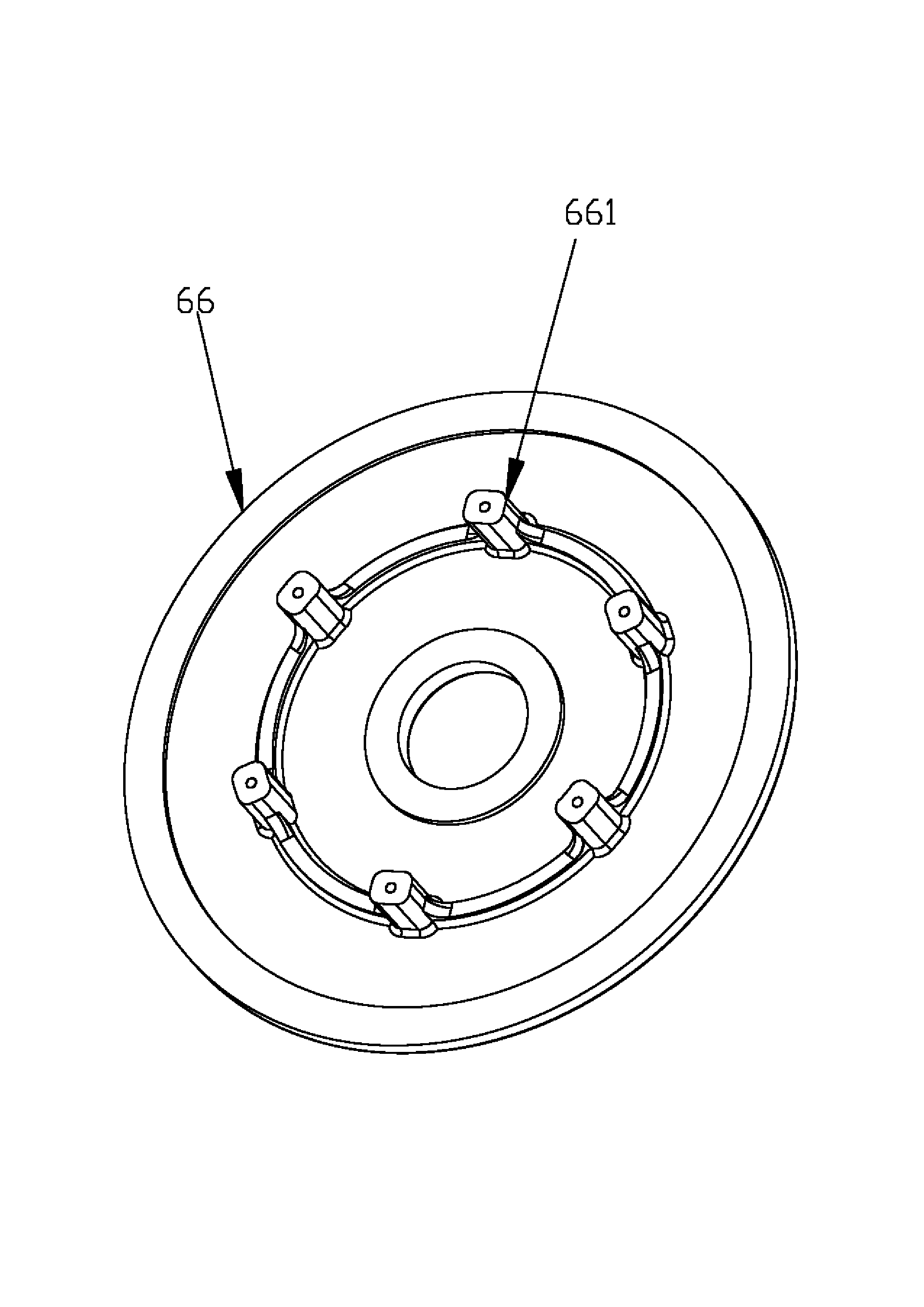

[0054] The heating plate assembly 6 includes:

[0055] The electromagnetic heating outer disk 61 is arranged in a bowl shape, and its bottom is sunken downward to form a receiving space, and the electromagnetic heating outer disk 61 is provided with a fan installation groove 615;

[0056] Radiating fan 62, which is installed in the fan installation groove 615;

[0057] Elect...

Embodiment 2

[0075] Embodiment 2 of an electromagnetically heated electric pressure cooker of the present invention is as figure 1 and Figure 8 Shown, its main technical scheme is identical with embodiment 1, and difference is:

[0076] The upper ring portion of the electromagnetic heating outer disk 61 is uniformly provided with several heat dissipation holes 614, and the wind generated by the cooling fan 62 passes through the air duct groove 632 and enters the air duct cavity 635 formed by the air duct groove 632 and the bottom of the electromagnetic heating outer disk 61 and The ventilation hole 634 circulates inside, and then the heat dissipation hole 614 discharges the hot air, thereby taking away the heat from the surface of the electromagnetic coil 64 to achieve a better heat dissipation effect.

Embodiment 3

[0078] A kind of embodiment 3 of the electric pressure cooker of electromagnetic heating of the present invention, its main technical scheme is identical with embodiment 1, and difference is:

[0079] The anti-magnetic disk 67 is arranged inside the electromagnetic heating outer disk 61 and integrally injection-molded with the electromagnetic heating outer disk 61, which is convenient for processing, and effectively prevents the electromagnetic coil from generating electromagnetic heating to the outer pot, thereby solving the problem of potential safety hazards in electric pressure cookers using electromagnetic heating technology.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com