Inorganic hybridized mixed-etherified melamine resin and preparation method thereof

A technology of etherified melamine resin and etherified melamine, which is applied in the field of inorganic hybrid polymer materials, can solve problems such as the gap in high temperature resistance, achieve high temperature resistance, improve high temperature resistance, flame retardancy, and excellent physical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

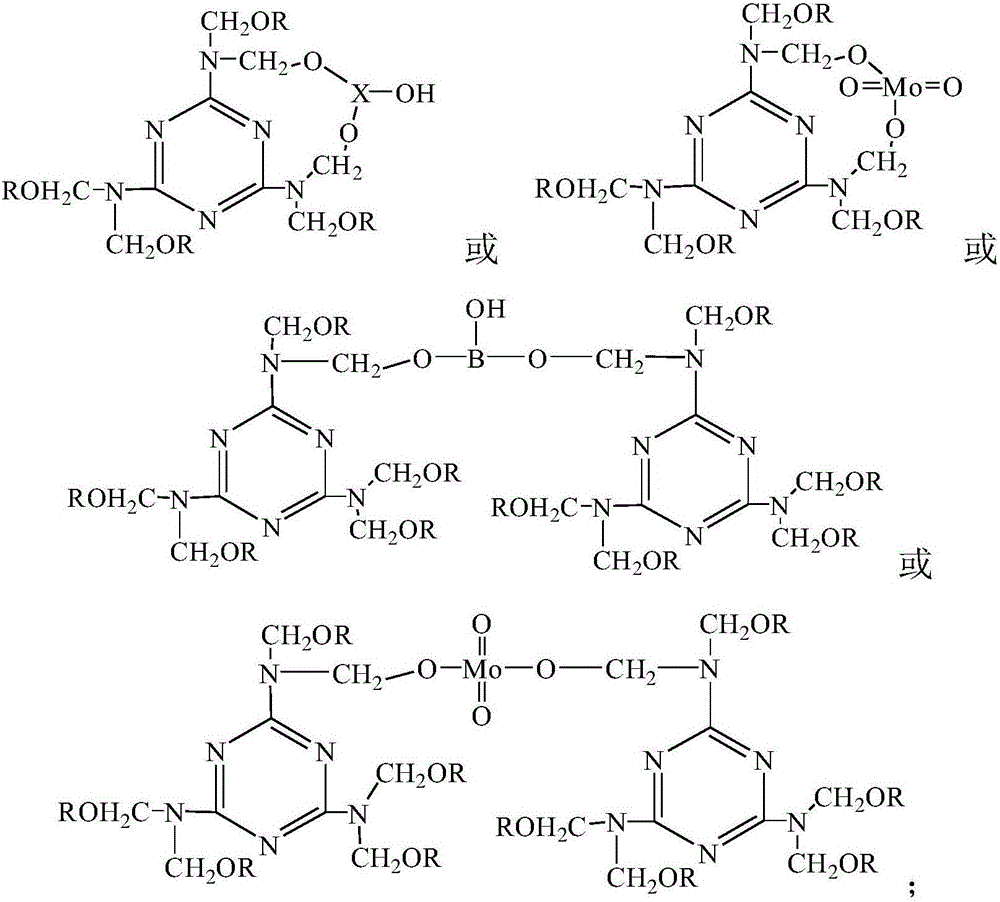

Method used

Image

Examples

Embodiment 1

[0037] Preparation of Boronized Mixed Etherified Melamine Resin

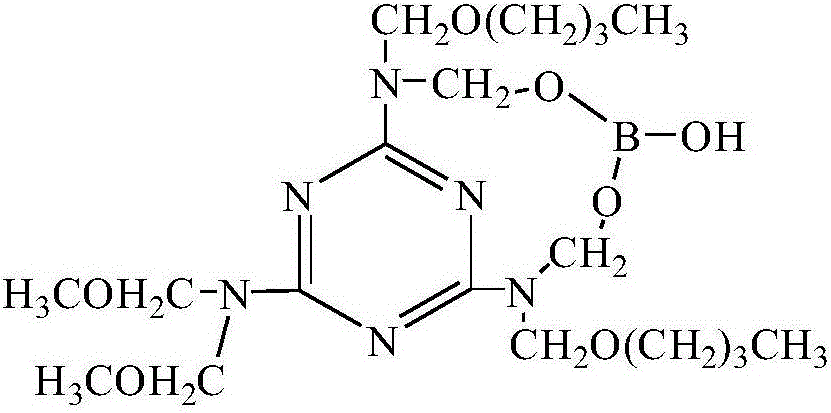

[0038] Molecular formula:

[0039]

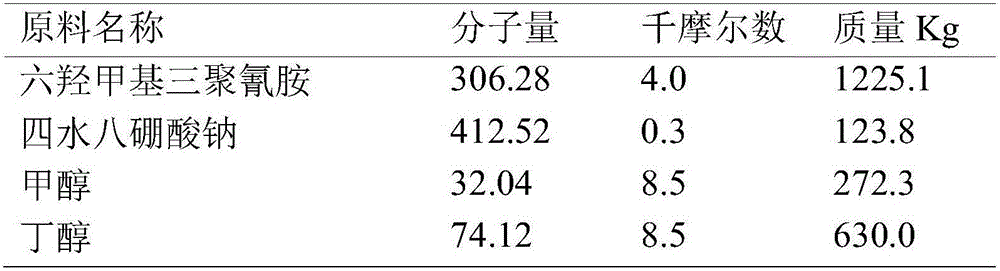

[0040] Raw material ratio:

[0041]

[0042] (1) etherification reaction

[0043] Add hexamethylol melamine, methanol and butanol into the reaction kettle according to the above ratio, add hydrochloric acid to adjust the pH to 2.5, and carry out the etherification reaction at 35°C with a stirring speed of 60 rpm and keep warm for 120 minutes to obtain a mixed ether Melamine resin;

[0044] (2) Alkaline neutralization

[0045] Stir at a speed of 40 rpm, add sodium hydroxide to adjust the pH to 8.0, and keep the temperature below 50°C during the alkali neutralization process;

[0046] (3) Hybridization reaction

[0047] Add sodium octaborate tetrahydrate and water into the reaction kettle, raise the temperature to 100°C and react for 2 hours, and the hybridization reaction is completed;

[0048] (4) distillation to remove residual methanol and butanol

[0049] Unde...

Embodiment 2

[0053] Preparation of antimony hybrid mixed etherified melamine resin

[0054] Molecular formula:

[0055]

[0056] Raw material ratio:

[0057]

[0058] (1) etherification reaction

[0059] Add hexamethylol melamine, methanol and butanol into the reaction kettle according to the above ratio, add nitric acid to adjust the pH to 5.5, and under the condition of 65°C, the stirring speed is 80 rpm, and the etherification reaction is carried out for 30 minutes to obtain a mixture Etherified melamine resin;

[0060] (2) Alkaline neutralization

[0061] Stir at a speed of 80 rpm, add potassium hydroxide to adjust the pH to 9.0, and keep the temperature below 50°C during the alkali neutralization process;

[0062] (3) Hybridization reaction

[0063]Add antimony trioxide and water into the reaction kettle, raise the temperature to 110°C and react for 0.5 hours, and the hybridization reaction is completed;

[0064] (4) distillation to remove residual methanol and butanol

...

Embodiment 3

[0069] Preparation of molybdenum hybrid mixed etherified melamine resin

[0070] Molecular formula:

[0071]

[0072] Raw material ratio:

[0073]

[0074] (1) etherification reaction

[0075] Add hexamethylolmelamine, methanol and butanol into the reaction kettle according to the above ratio, add hydrochloric acid to adjust the pH to 4.5, and under the condition of 55°C, the stirring speed is 75 rpm, and the etherification reaction is carried out for 90 minutes after heat preservation to obtain a mixture Etherified melamine resin;

[0076] (2) Alkaline neutralization

[0077] Stir at a speed of 60 rpm, add alkali to adjust the pH to 8.6, and keep the temperature below 50°C during the alkali neutralization process;

[0078] (3) Hybridization reaction

[0079] Add sodium molybdate and water into the reaction kettle, raise the temperature to 100°C and react for 1.5 hours, and the hybridization reaction is completed;

[0080] (4) distillation to remove residual methan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com