Glass fiber reinforced flame retardant polypropylene material for household appliance products and preparation method thereof

A technology for flame-retardant polypropylene and household appliances, which is applied in the field of glass fiber-reinforced flame-retardant polypropylene materials for household appliances and its preparation. It can solve the problems of poor flame retardancy and achieve good flame retardancy, low cost, and high impact strength. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The present invention also proposes a method for preparing the above-mentioned glass fiber reinforced flame-retardant polypropylene material for household electrical appliances, comprising the following steps:

[0025] 1) After the brominated flame retardant, antimony trioxide, flame retardant synergist, toughening agent, compatibilizer, lubricant, ultraviolet absorber and antioxidant are prepared according to the proportions, pre-mix in a low-speed mixer 1min;

[0026] 2) Add the high impact polypropylene copolymer into the low-speed mixer, and mix it with the material after step 1) in the low-speed mixer for 1 min, and then feed the material from the main feeding system to the twin-screw extruder;

[0027] 3) Add alkali-free continuous long glass fiber into the twin-screw extruder from the fiber feeding port of the twin-screw extruder;

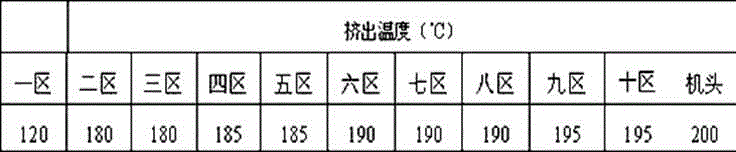

[0028] 4) The material after step 3) is mixed in a twin-screw extruder with a screw diameter of 30-75 mm and an aspect rat...

Embodiment 1

[0031] The glass fiber reinforced flame-retardant polypropylene material used in the household electrical appliances of the present embodiment is composed of the following raw materials measured in parts by weight:

[0032] 40 parts of high impact copolymer polypropylene resin, 20 parts of alkali-free continuous long glass fiber, 6 parts of brominated flame retardant, 3 parts of antimony trioxide, 2 parts of flame retardant synergist, 3 parts of compatibilizer, toughening 0 part of the agent, 0.5 part of the lubricant, 0.2 part of the ultraviolet absorber, and 0.3 part of the antioxidant.

Embodiment 2

[0034] The glass fiber reinforced flame-retardant polypropylene material used in the household electrical appliances of the present embodiment is composed of the following raw materials measured in parts by weight:

[0035] 43 parts of high impact copolymer polypropylene resin, 21 parts of alkali-free continuous long glass fiber, 8 parts of brominated flame retardant, 2.7 parts of antimony trioxide, 2.7 parts of flame retardant synergist, 4 parts of compatibilizer, toughening 1 part of lubricant, 0.5 part of lubricant, 0.2 part of ultraviolet absorber, and 0.3 part of antioxidant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com