Hydraulic control mechanism for vanes

A technology of hydraulic control mechanism and vane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

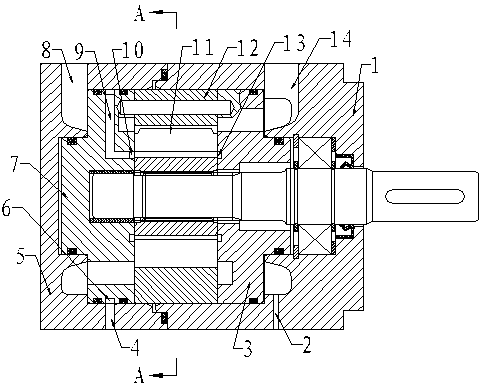

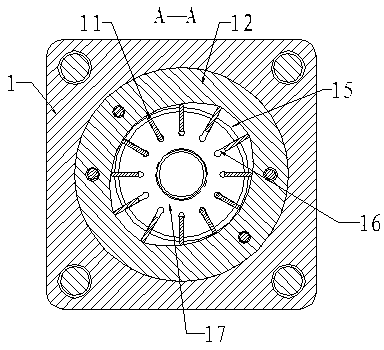

[0028] The structure of the vane pump with hydraulic control mechanism of the present invention includes a casing, a stator 12 and a rotor 17 . Both ends of the housing are respectively provided with an inlet 14 and an outlet 8, the inlet 14 is used to communicate with the oil tank, and the outlet 8 is used to communicate with the outlet pipeline in the hydraulic system.

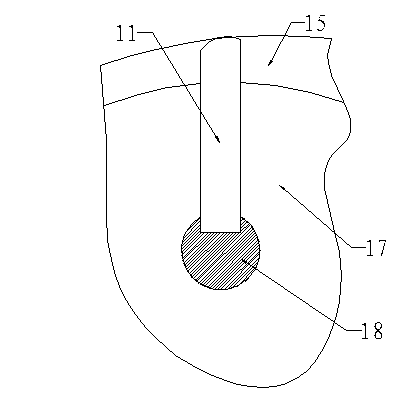

[0029] The rotor 17 is arranged in the stator 12 coaxially with a gap, the rotor 17 can rotate in the stator 12, and both the rotor 17 and the stator 12 are arranged in the casing. A plurality of vane slots 16 are arranged on the rotor 17 along its radial direction, and the openings of the vane slots 16 are located on the outer peripheral surface of the rotor 17 . Each vane slot 16 is provided with a vane 11 , and the dimension of the vane 11 along the axial direction of the rotor 17 is equal to or slightly smaller than the dimension of the vane slot 16 along the axial direction of the rotor 17 . When the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com