Atomizer and electronic smoking device

A technology for nebulizers and power supply devices, applied in electric heating devices, nebulizers for treatment, transportation and packaging, etc., which can solve problems such as inability to realize automatic production, shortened service life of nebulizers, and uneven heating of e-liquid , to avoid uneven heating, prevent internal pressure increase, prevent heat loss or heat conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In the following, specific embodiments will be used to further illustrate the structure and principle of use of the atomizer and electronic smoking device of the present invention.

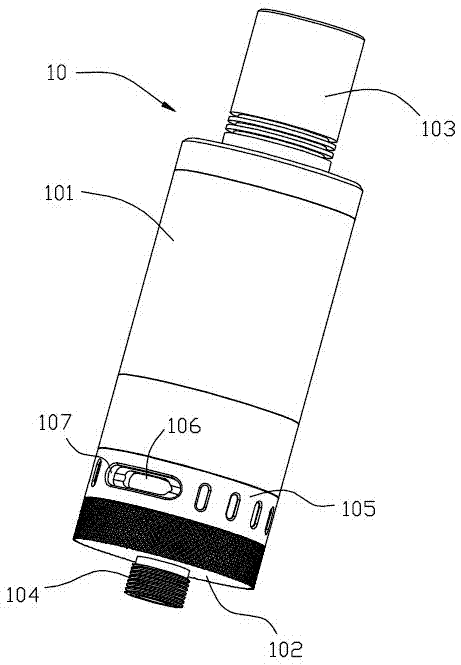

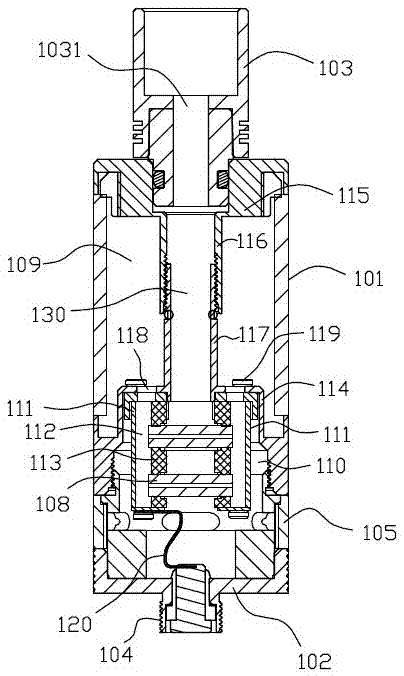

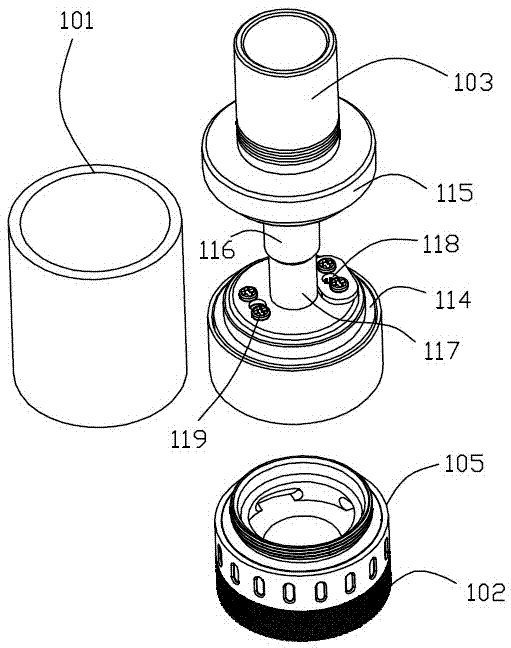

[0027] See figure 1 As shown, this embodiment provides an atomizer 10, which is generally cylindrical in appearance, including a housing 101, suction nozzles 103 and conductive parts 102 arranged at both ends of the housing 101, and threaded parts are provided on the conductive parts 102. 104. It is used to connect a power supply device to power the atomizer 10. The housing 101 is provided with a liquid storage cavity for containing the e-liquid and a heating element for heating the e-liquid, which will be described in detail later. The middle section of the housing 101 is made of transparent material, such as glass or transparent plastic, to facilitate observation and storage. The condition of the smoke liquid in the liquid cavity. An air inlet 106 is provided on the housing 101, and an adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com