Multifunctional pot

A multifunctional pot and pot body technology, which is applied in the field of kitchen utensils, can solve the problems of uneven heating of the pot body, uneven heating of the pot body, and low energy utilization rate, so as to avoid uneven heating, reduce heat transfer, and improve energy utilization. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

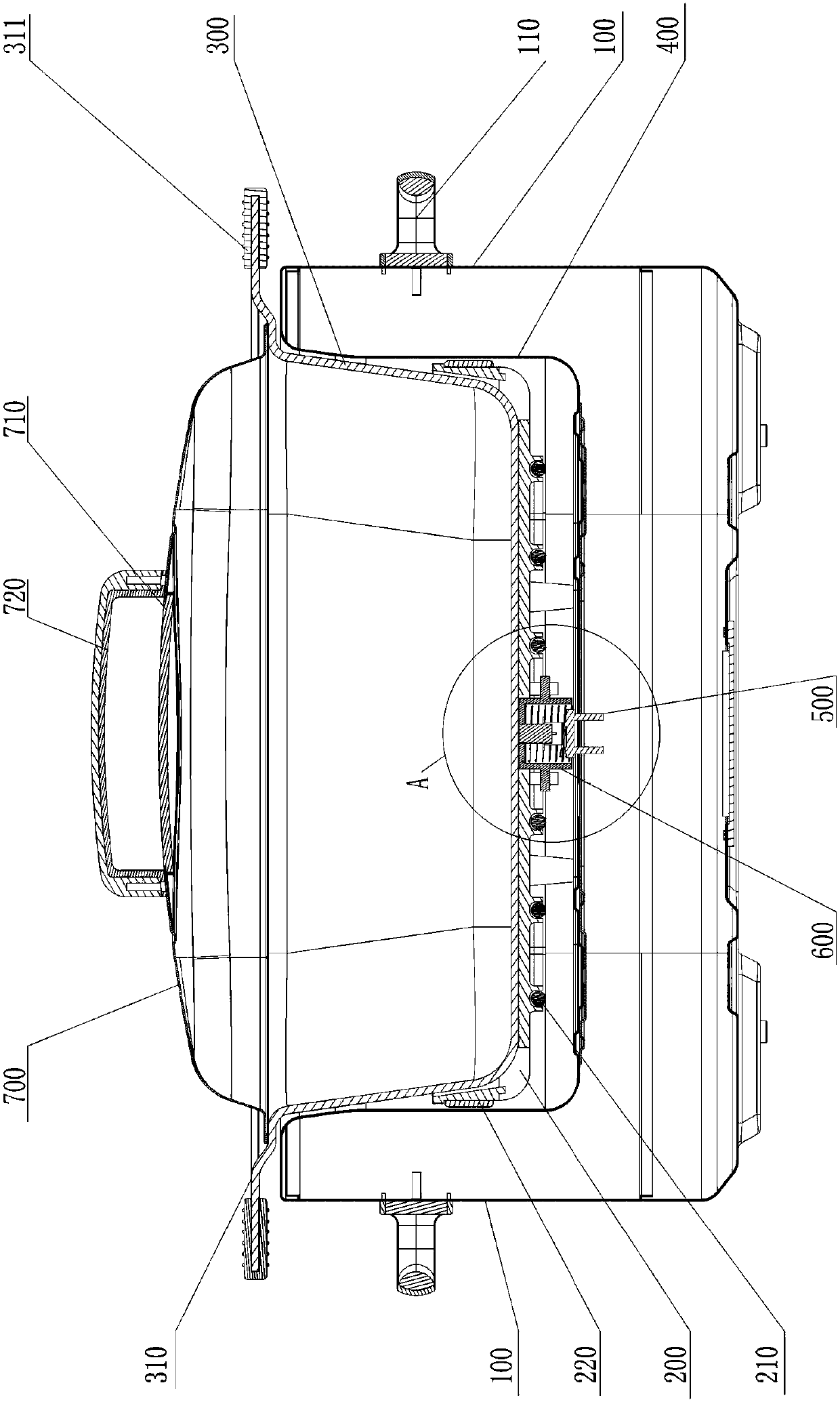

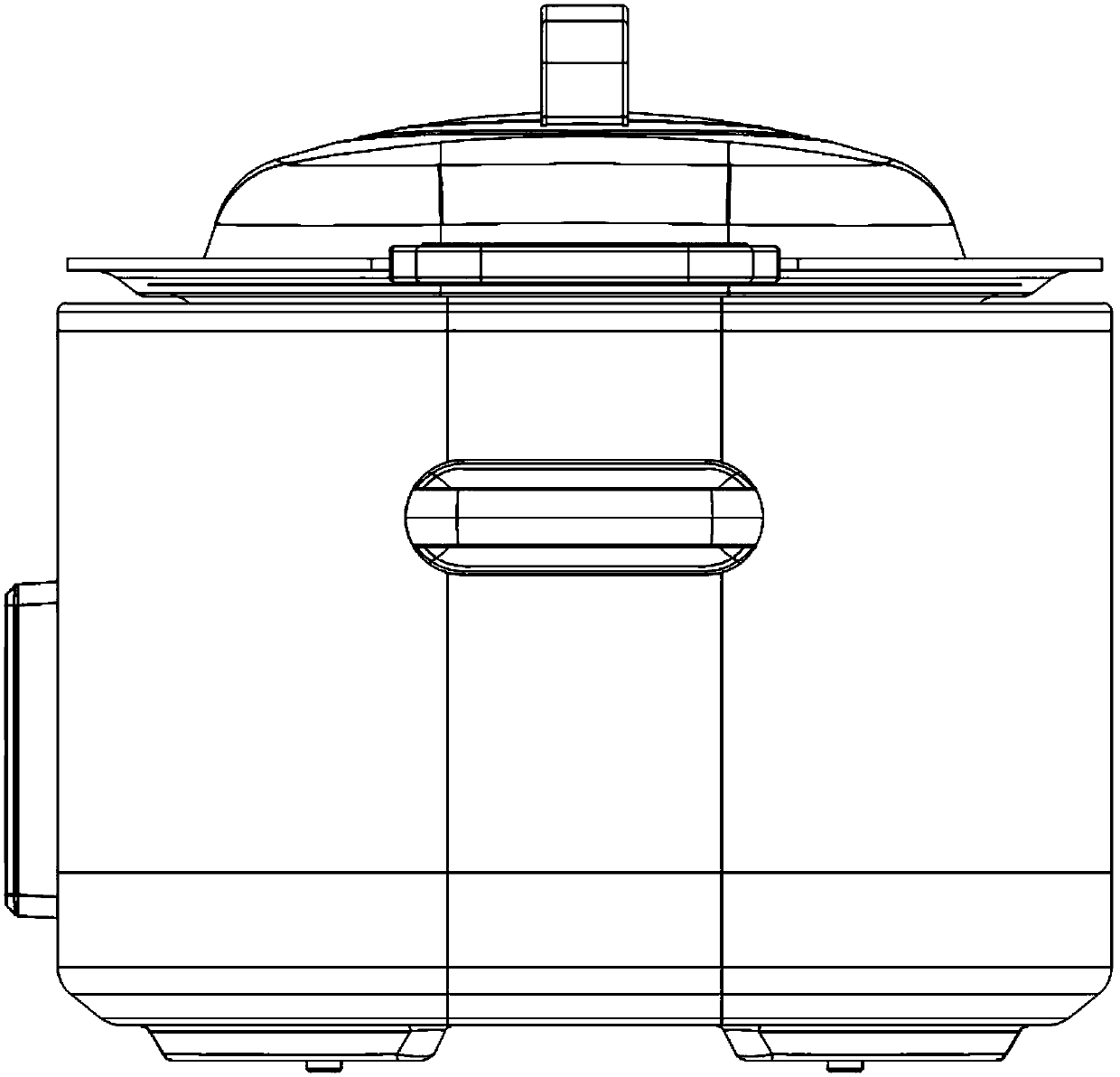

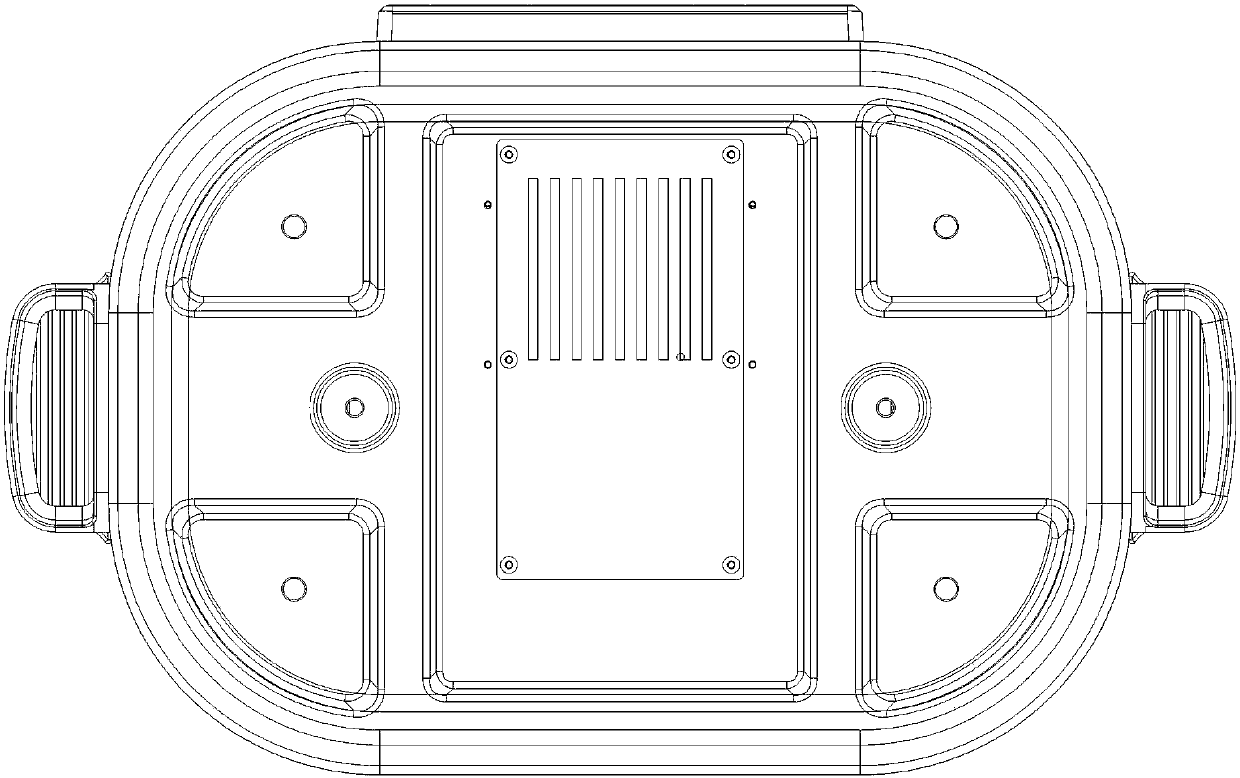

[0030] This embodiment provides a multifunctional pot, such as Figure 1-7 As shown, it includes a casing 100, a heating element heat conducting plate 200 and a pot body 300. An inner container 400 is arranged inside the casing 100, and the upper end of the casing 100 is connected to the upper end of the inner container 400; And the height of the heating element heat conducting plate 200 is lower than the depth of the inner tank 400, the outer bottom surface of the heating element heat conducting plate 200 is provided with a bottom heating element 210 for heating the bottom of the heating element heat conducting plate 200, and on the outer wall of the heating element heat conducting plate 200 There is an annular heating element 220 for heating the side wall of the heating element heat conduction plate 200, the bottom heating element 210 and the annular heating element 220 are connected in parallel and electrically connected to the working circuit of the multifunctional pot; Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com