Heater for crucible, crucible and evaporation source

A heating device and evaporation source technology, applied in vacuum evaporation plating, metal material coating process, coating, etc., can solve the problem of uneven heating of evaporation materials, so as to avoid uneven heating, improve uniformity, and improve purity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

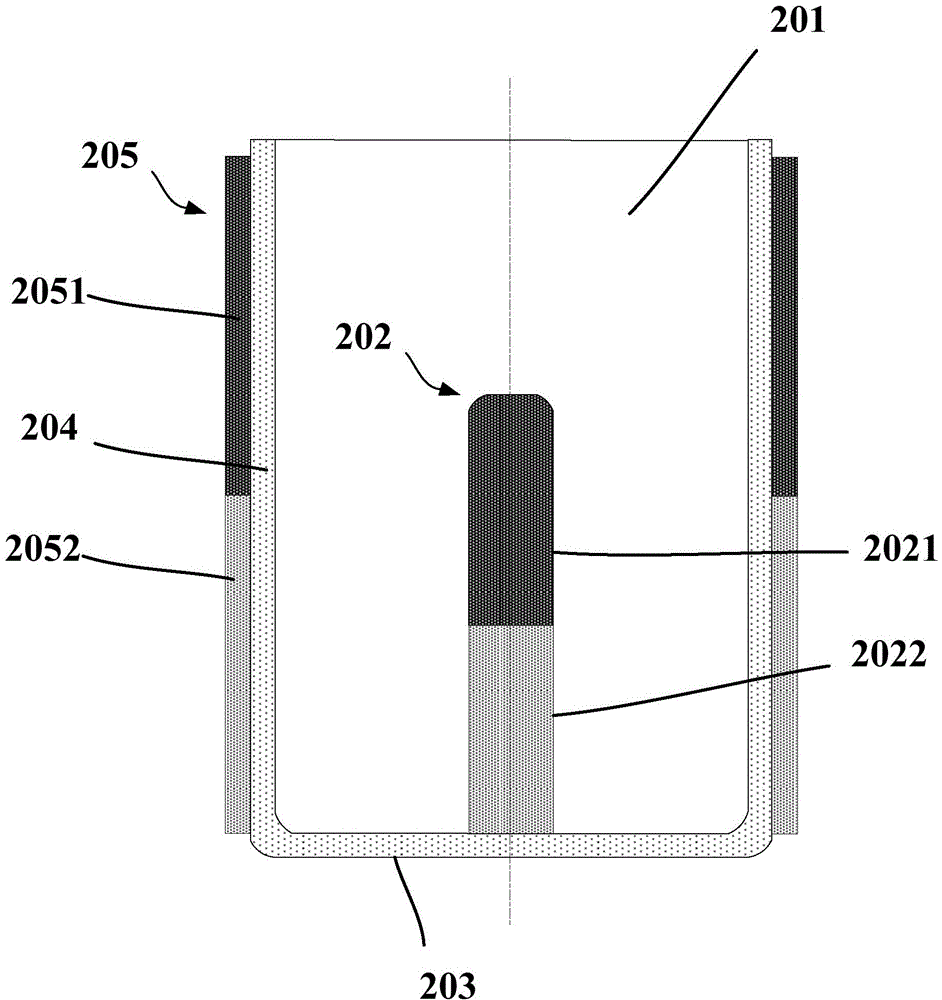

[0025] In order to solve the problem of uneven heating of evaporation materials by existing evaporation sources, please refer to figure 2 , an embodiment of the present invention provides a heating device for a crucible, the heating device for a crucible includes a housing chamber 201 for housing a crucible, and a middle heater 202 disposed in the housing chamber 201, the middle heater 202 is used for Heating the evaporation material located in the middle of the crucible.

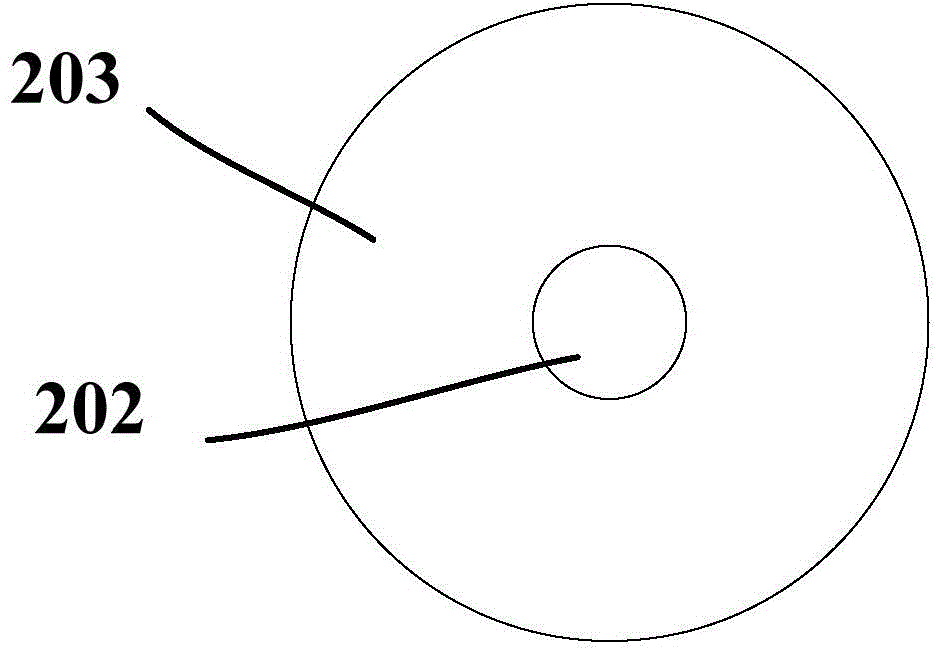

[0026] In this embodiment, the accommodating cavity 201 is surrounded by a bottom wall 203 and a side wall 204, an opening for installing a crucible is opened at a position opposite to the bottom wall, and the central heater 202 is arranged on the inside of the bottom wall 203 middl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com