Flexible far infrared heating aramid nano-fiber thin film and preparation method

A far-infrared heating and nanofiber technology, which is applied in the direction of non-fibrous pulp addition, fiber raw material treatment, cellulose pulp post-treatment, etc., can solve the problems of difficult dispersion and easy agglomeration, and achieve the promotion of dispersion, stable heating performance and improved dispersion Effects of properties and film-forming properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

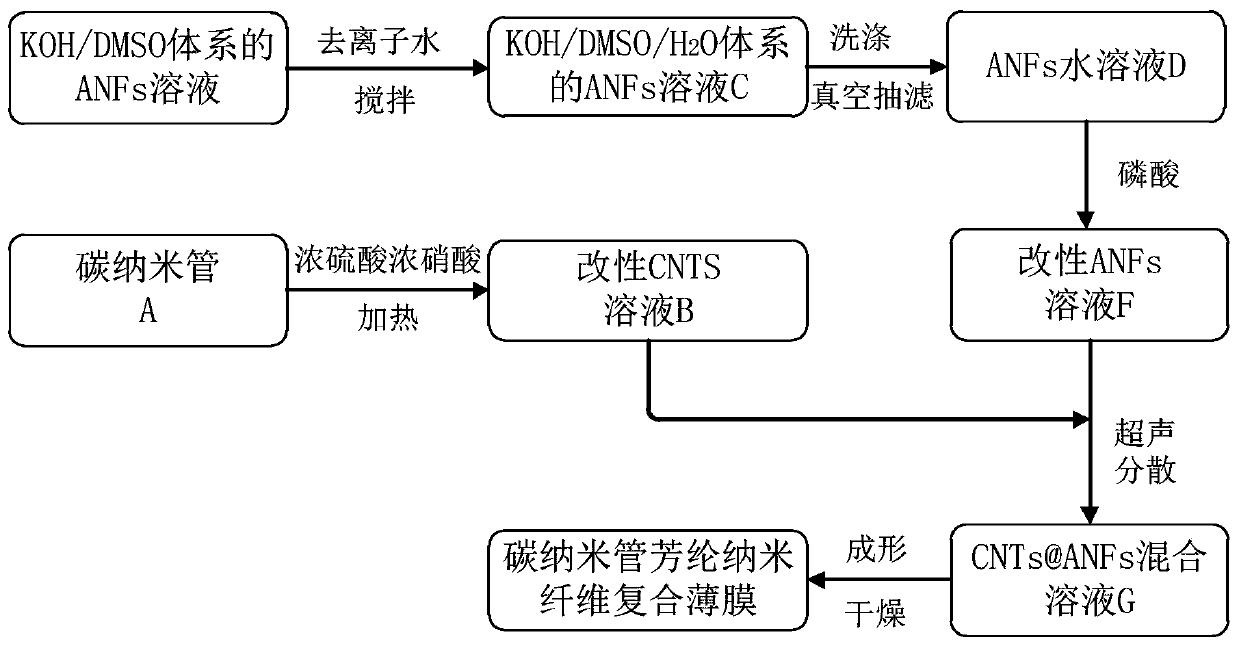

Method used

Image

Examples

Embodiment 1

[0040] Step (1): Stir the carbon nanotube A in a mixed solution of concentrated sulfuric acid and concentrated nitric acid at a certain temperature, the stirring speed is 500 rpm, the temperature is 60°C, and the mass ratio of concentrated sulfuric acid to concentrated nitric acid is 3:1 to obtain uniformly dispersed modified Carbon nanotube solution B;

[0041] Step (2): The para-aramid nanofiber solution in the DMSO / KOH system is stirred at a stirring speed of 800rpm, and deionized water is injected into it under high pressure to obtain a solution dispersed in DMSO / KOH / H 2 Para-aramid fiber nanofiber solution C in O mixed system;

[0042] Step (3): Wash the para-aramid nanofiber solution C in the mixed system obtained in (2) with deionized water and ethanol under vacuum filtration until it becomes colloidal, and then disperse it in deionized water to obtain a solution dispersed in water The para-aramid nanofiber solution D;

[0043] Step (4): Phosphoric acid is added to th...

Embodiment 2

[0047] Step (1): Stir carbon nanotube A in a mixed solution of concentrated sulfuric acid and concentrated nitric acid at a certain temperature, the stirring speed is 700rpm, the temperature is 50°C, and the mass ratio of concentrated sulfuric acid to concentrated nitric acid is 1:1, and a uniformly dispersed modified Carbon nanotube solution B;

[0048] Step (2): The para-aramid nanofiber solution in the DMSO / KOH system is stirred at a stirring speed of 1000rpm, and deionized water is injected into it under high pressure to obtain a solution dispersed in DMSO / KOH / H 2 Para-aramid fiber nanofiber solution C in O mixed system;

[0049] Step (3): Wash the para-aramid nanofiber solution C in the mixed system obtained in (2) with deionized water and ethanol under vacuum filtration until it becomes colloidal, and then disperse it in deionized water to obtain a solution dispersed in water The para-aramid nanofiber solution D;

[0050] Step (4): Phosphoric acid is added to the solut...

Embodiment 3

[0054] Step (1): Stir the carbon nanotubes A in a mixed solution of concentrated sulfuric acid and concentrated nitric acid at a certain temperature, the stirring speed is 500 rpm, the temperature is 40°C, the mass ratio of concentrated sulfuric acid to concentrated nitric acid is 1:1, and a uniformly dispersed modified Carbon nanotube solution B;

[0055] Step (2): The para-aramid nanofiber solution in the DMSO / KOH system is stirred at a stirring speed of 900rpm, and deionized water is injected into it under high pressure to obtain a solution dispersed in DMSO / KOH / H 2 Para-aramid fiber nanofiber solution C in O mixed system;

[0056] Step (3): Wash the para-aramid nanofiber solution C in the mixed system obtained in (2) with deionized water and ethanol under vacuum filtration until it becomes colloidal, and then disperse it in deionized water to obtain a solution dispersed in water The para-aramid nanofiber solution D;

[0057] Step (4): Phosphoric acid is added to the solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com