Patents

Literature

37results about How to "Improve uneven heating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

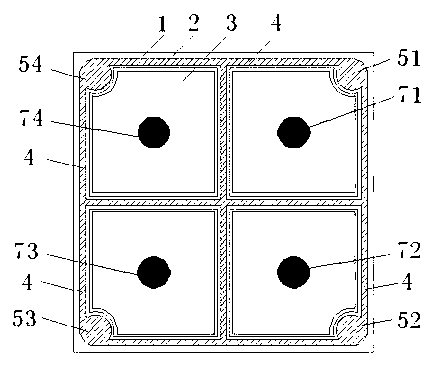

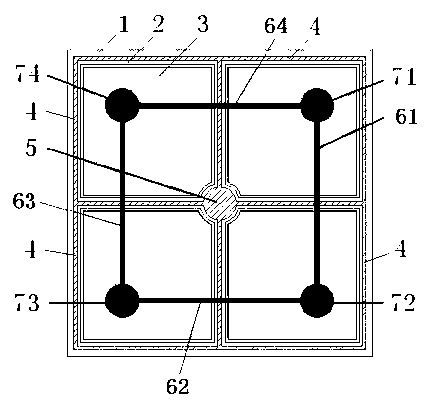

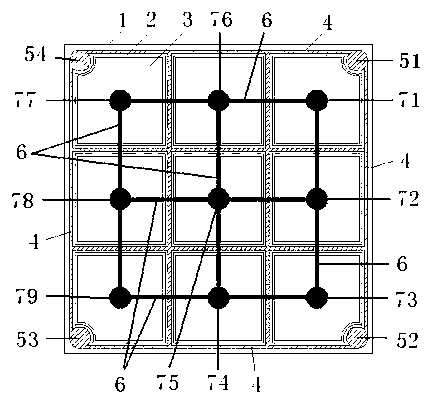

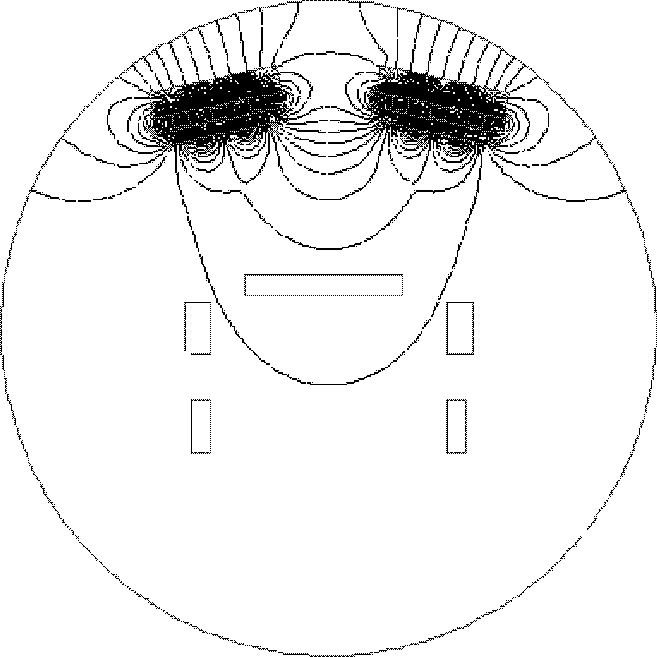

Network-shaped electrode applicable to high-power GaN-based LED chips

InactiveCN102709432AMany symmetrical elementsHas quadratic axisymmetricSemiconductor devicesCurrent distributionEngineering

The invention relates to the technical field of semiconductor illumination and provides a network-shaped electrode applicable to high-power GaN-based LED chips. Each electrode of a chip is composed of a network-shaped electrode and metal pads, the adopted electrodes at least have center inversion symmetry, secondary axial symmetry and quartic axial symmetry, wherein the secondary axial symmetry and the quartic axial symmetry are achieved by surrounding and being perpendicular to the center normal of the chip, and accordingly the electrodes can coincide when the chip rotates by 180 degrees, 270 degrees and 360 degrees around the center normal. A portion above an N-type GaN layer in an epitaxial layer is divided into multiple independent units not contacting with one another by the aid of N-type electrode slots on a projection plane perpendicular to the chip central axis, so that the units are unaffected by one another. Current distribution is more even by more electrode symmetry elements, and uneven heating of the chip is improved effectively. P-type metal pads and N-type metal pads can be selectively connected during routing by the aid of high symmetry of the P-type metal pads and the N-type metal pads, and accordingly flexibility of routing is improved.

Owner:施科特光电材料(昆山)有限公司

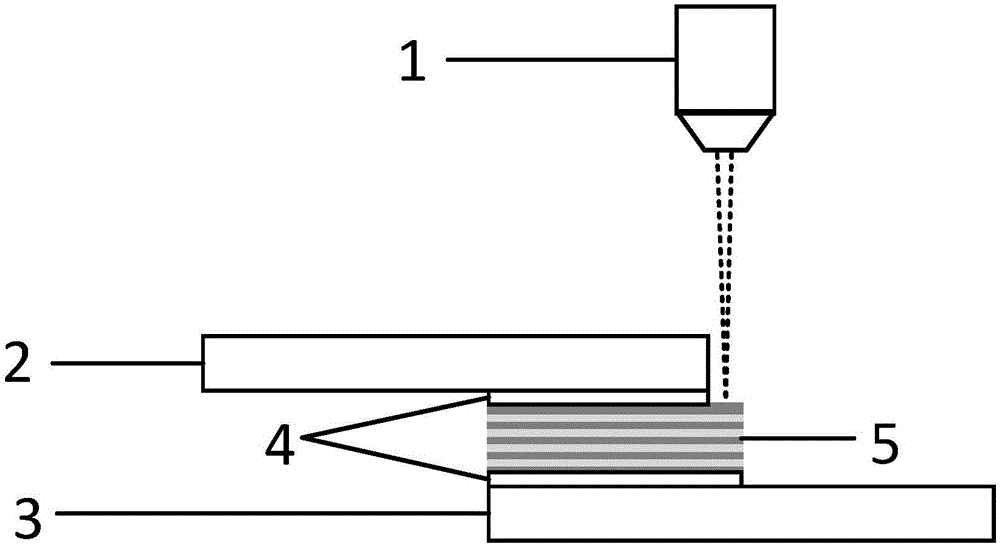

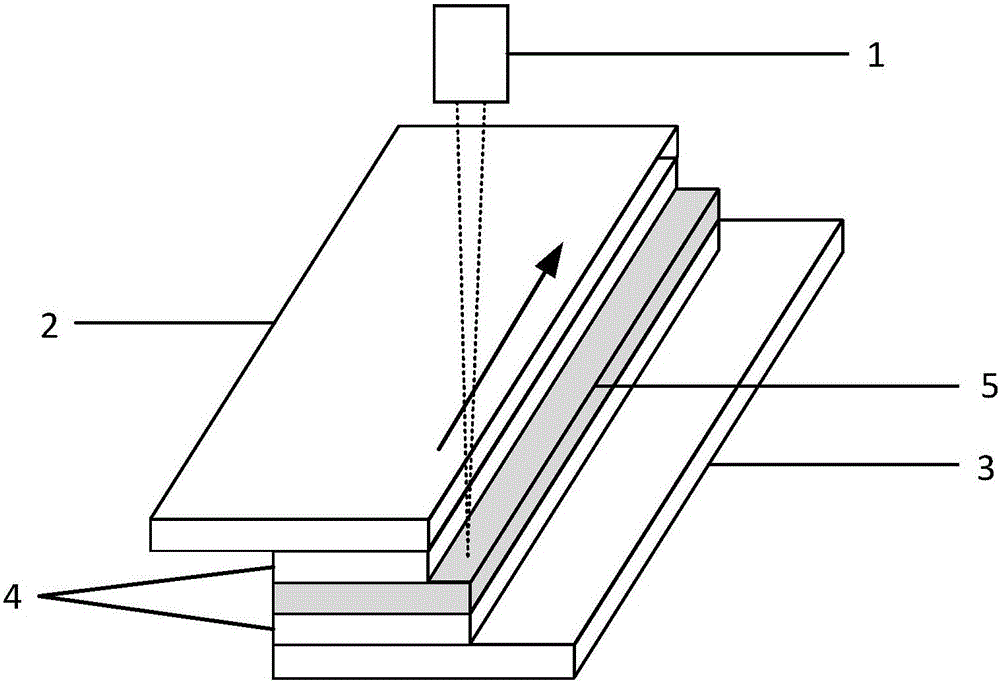

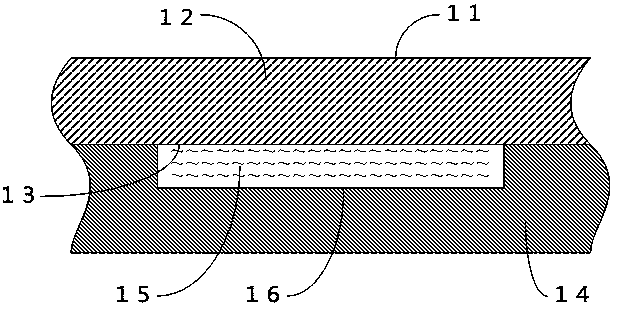

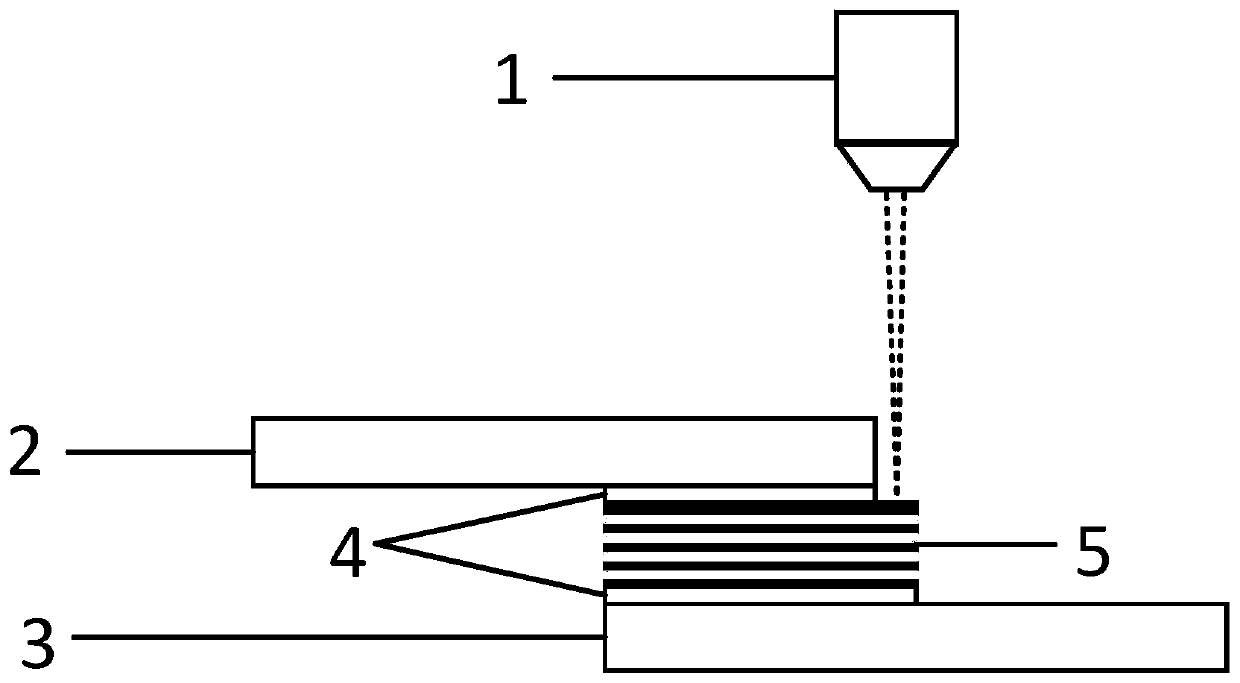

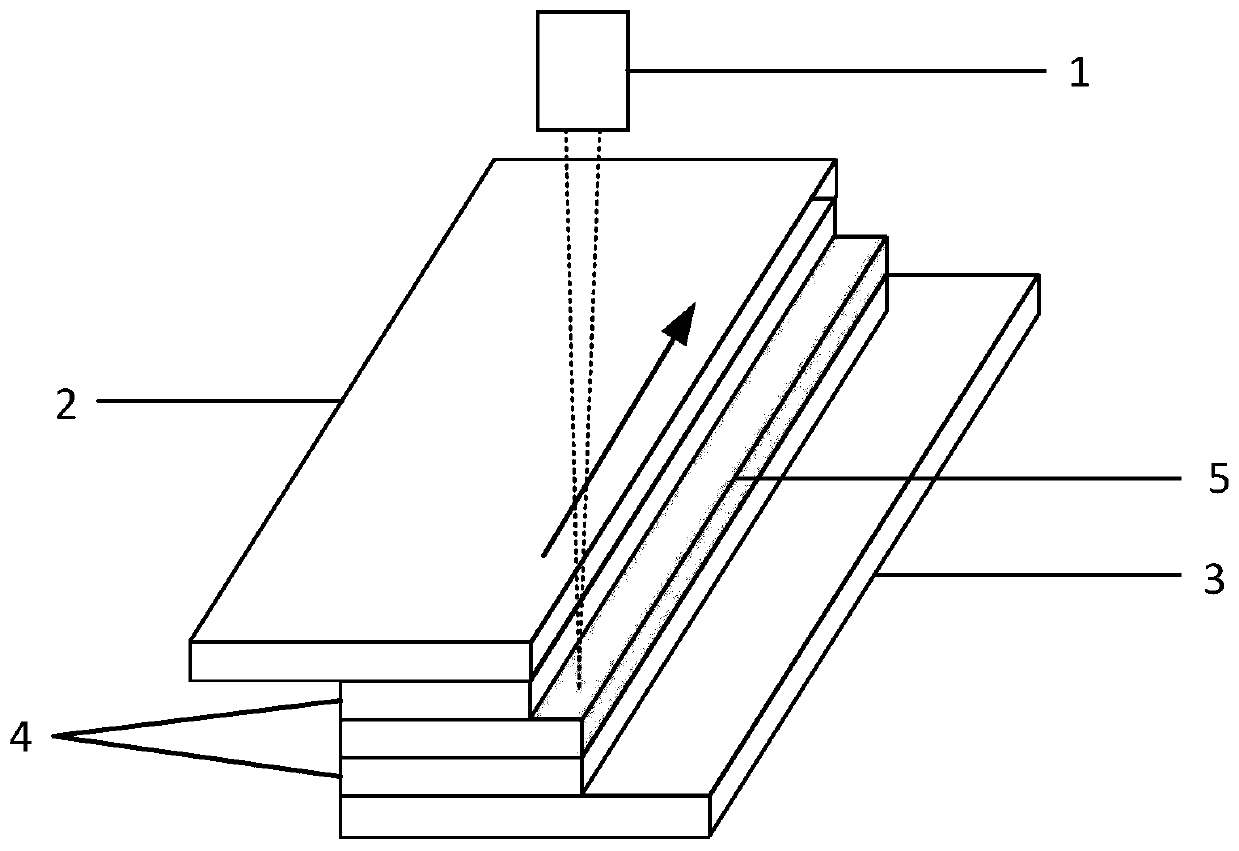

Method for assisting high-temperature laser brazing through self-propagating reaction of nano-multilayer film

InactiveCN106695141AIncrease joint areaImprove connection strengthSoldering apparatusWelding apparatusLap jointOptoelectronics

The invention belongs to the technical field of laser welding, and provides a method for assisting high-temperature laser brazing through self-propagating reaction of a nano-multilayer film. A double-metal nano-film is alternately deposited on a substrate by adopting a magnetron sputtering method; the deposited double-metal nano-multilayer film is stripped from the substrate; the stripped multilayer film is arranged between two layers of brazing materials, so that a composite intermediate layer is formed; surface pretreatment is conducted on base materials to be welded; and the composite intermediate layer is arranged between obtained base materials, a lap joint mode is adopted for welding, and lasers are adopted for carrying out scanning welding on the composite intermediate layer. The nano-multilayer film is subjected to the self-propagating reaction after being ignited by the lasers, a large amount of heat released by the reaction can melt low-melting-point brazing materials, and thus connection is achieved on both lap joints and whole lap-joint faces in the welding process, so that the joint connecting strength is improved, and material connection is completed. By means of the method, heating nonuniformity of the lasers used as local heat sources can be relieved, the more uniform interface reaction is achieved, and the joint density can be increased.

Owner:BEIJING UNIV OF TECH

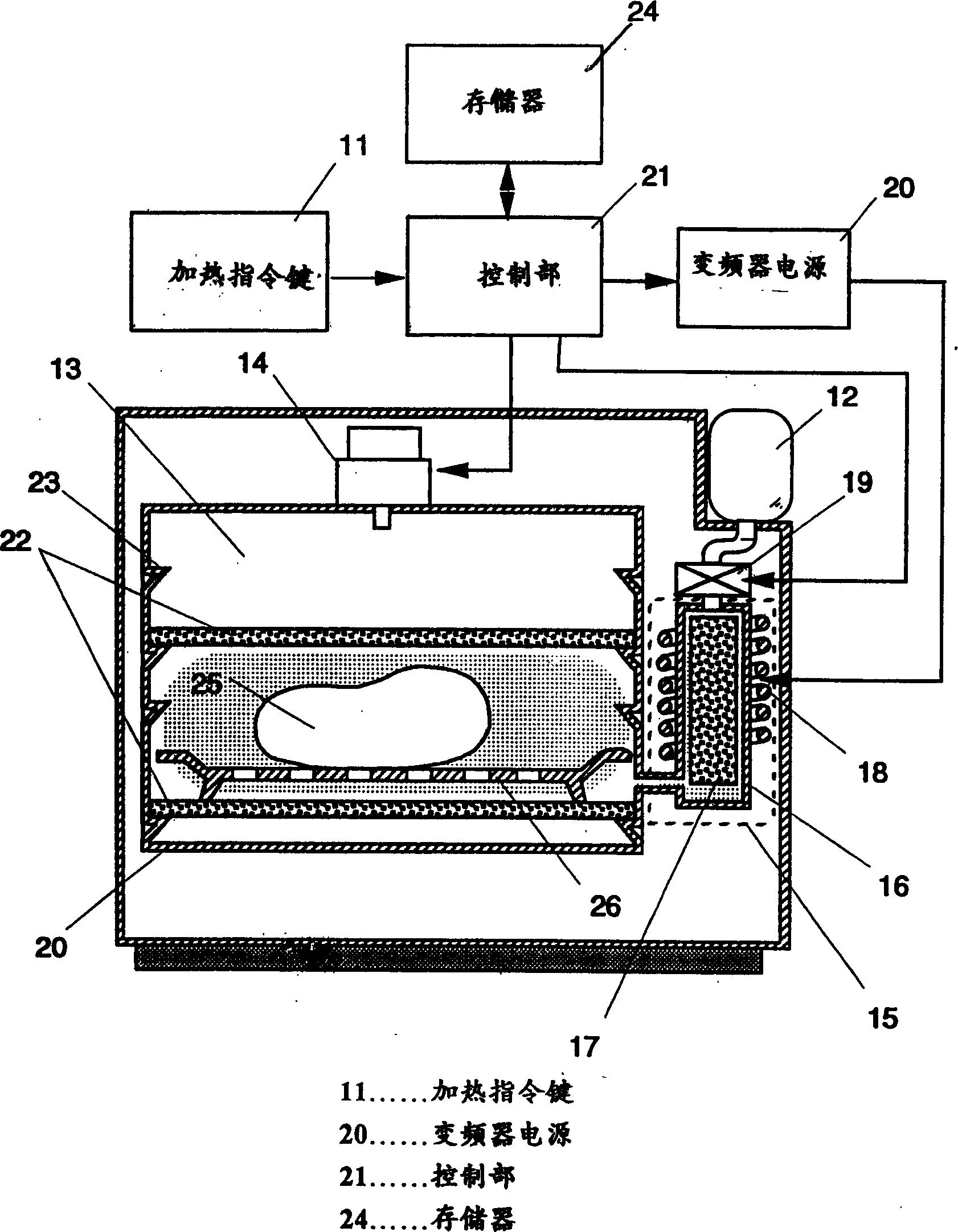

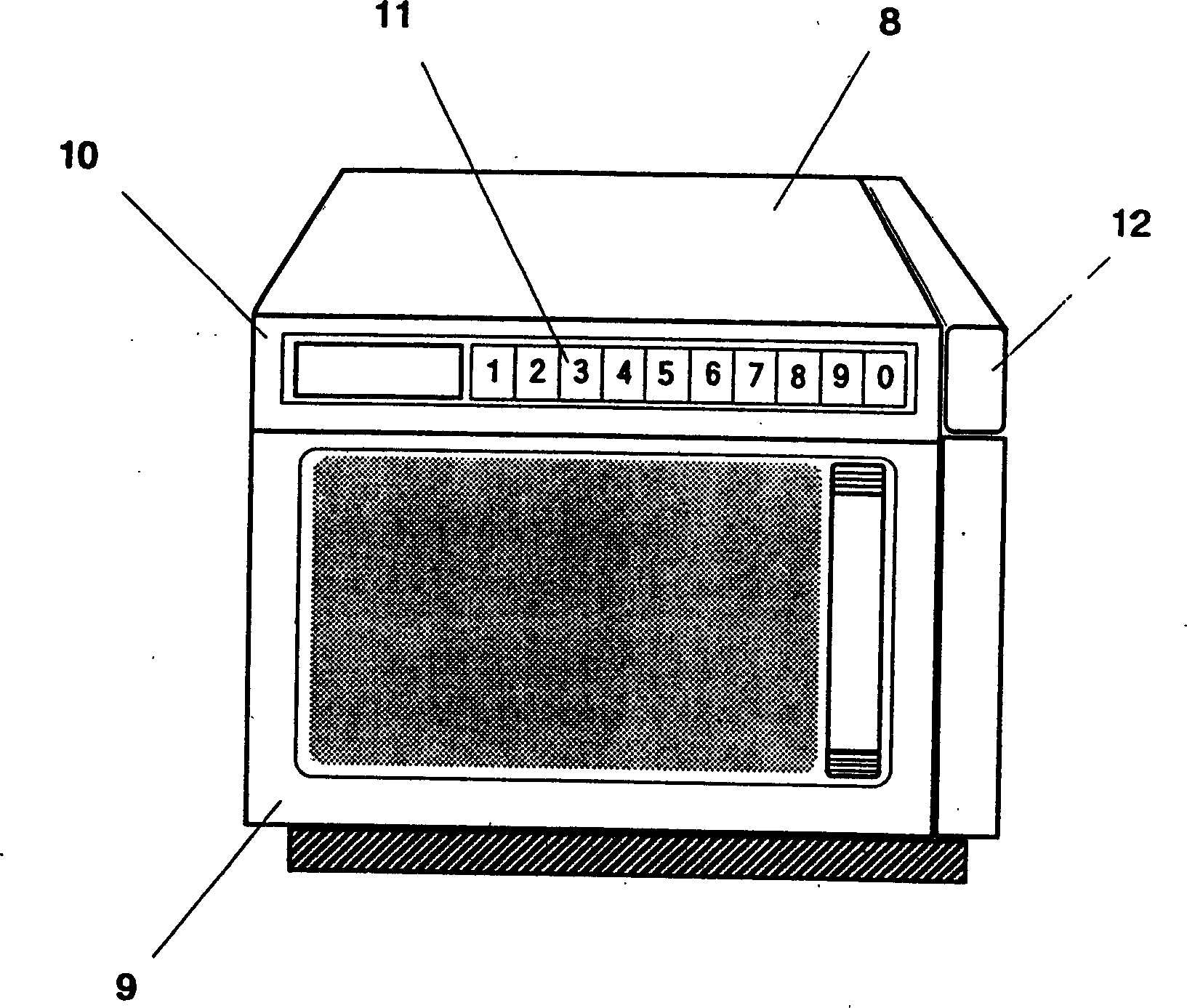

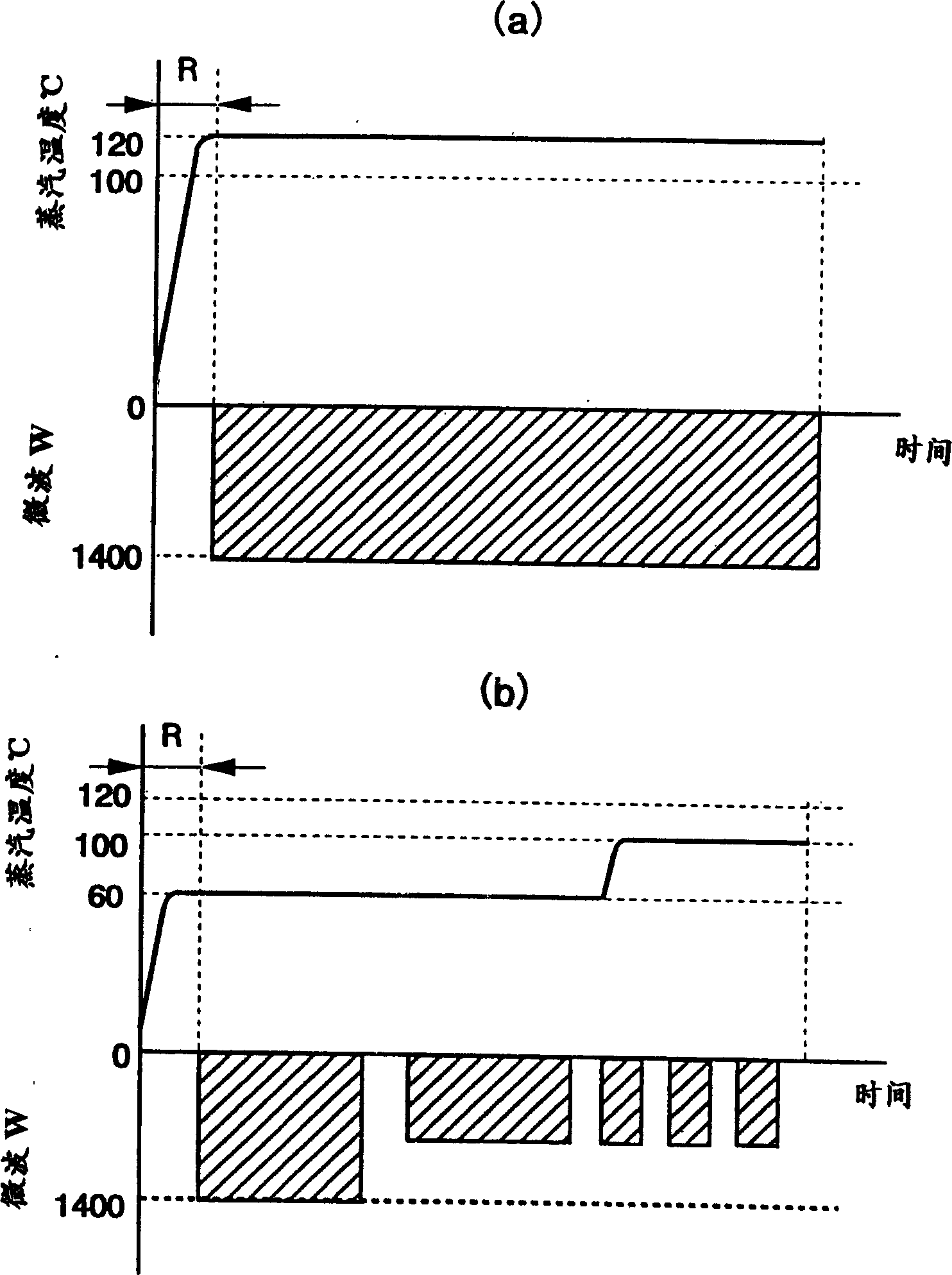

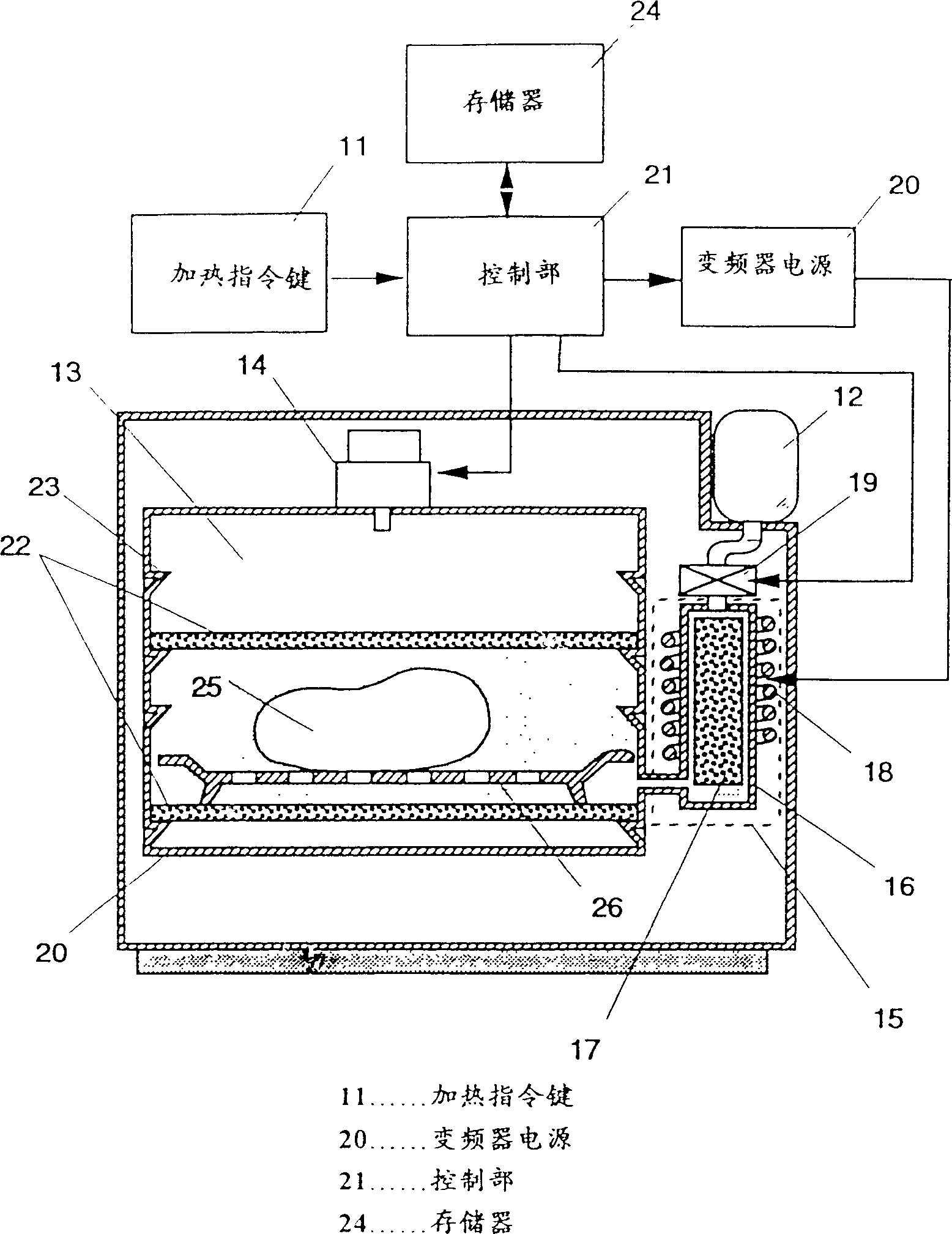

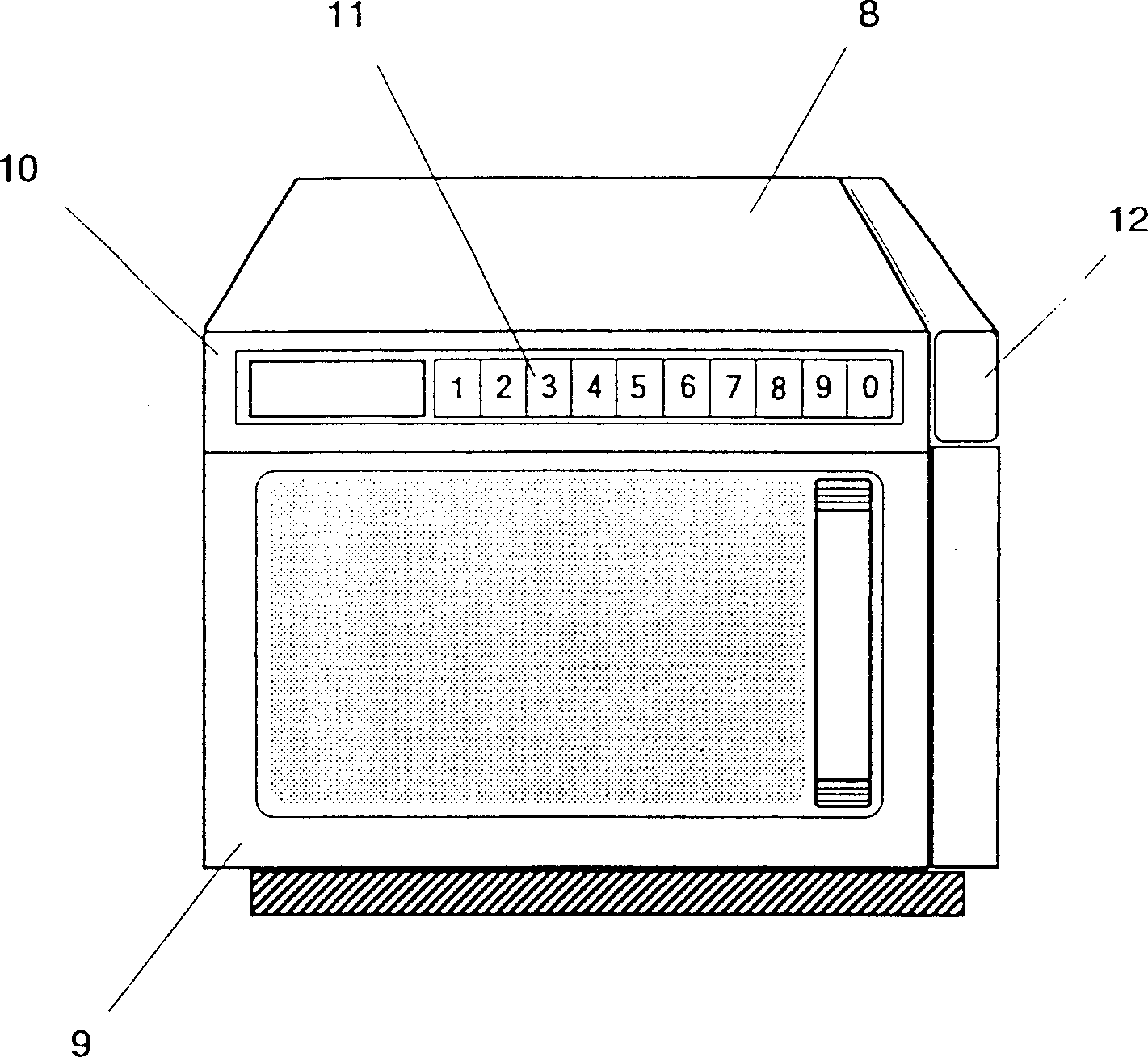

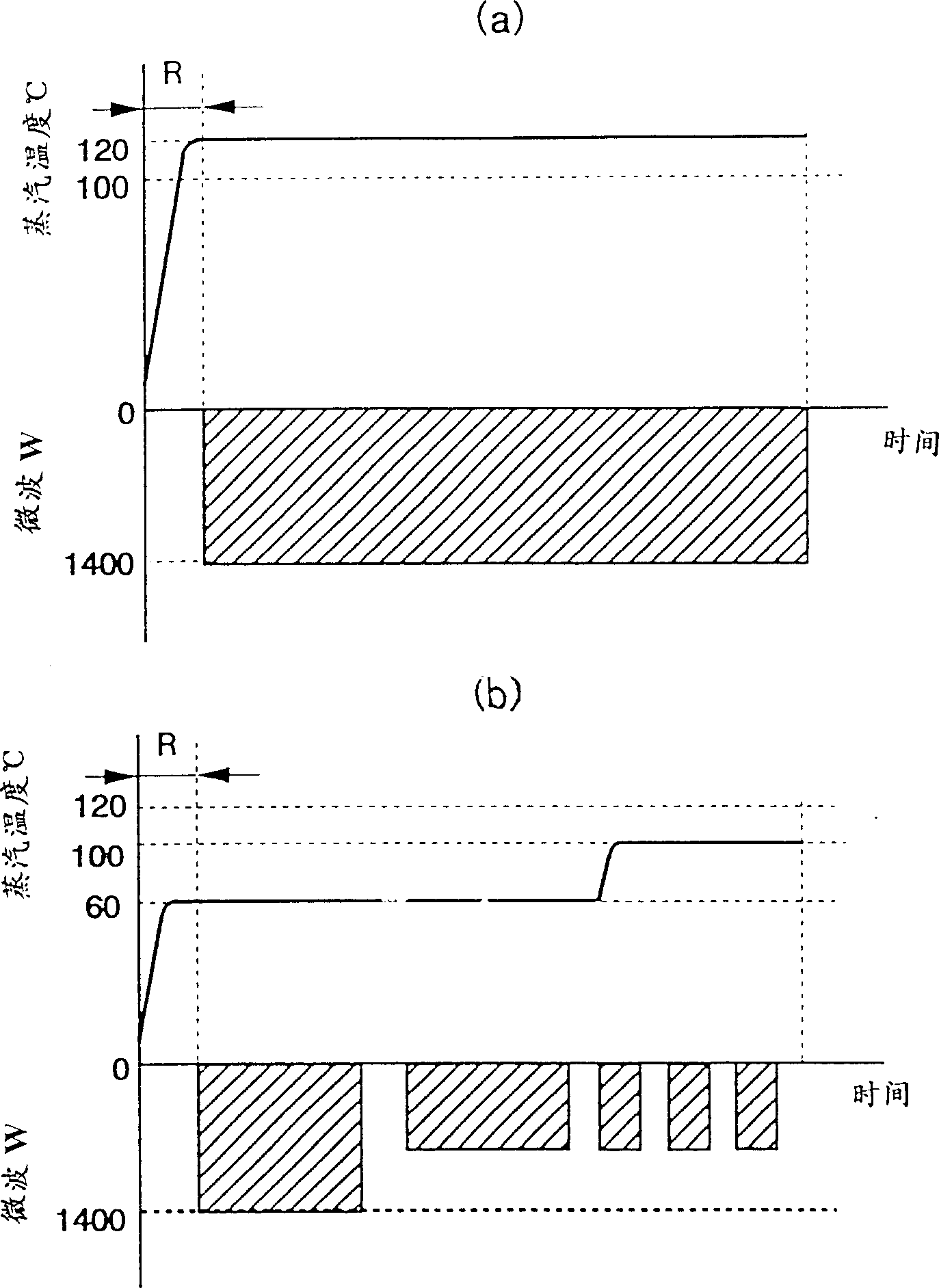

Microwave heating device

InactiveCN1526992AEasy to produceQuality declineDomestic stoves or rangesLighting and heating apparatusMicrowaveEngineering

An object such as food is heated favorably by means of microwaves while enclosing the food with superheated steam. The apparatus comprises a heating chamber in which an object to be heated is put, steam generating means for supplying superheated steam to the heating chamber, superheated steam maintaining means provided in the heating chamber to prevent the temperature of the superheated steam in the heating chamber from lowering, and microwave generating means for irradiating the object with microwaves. The object placed in the heating chamber is heated in superheated steam with microwaves, so that the food is efficiently heated from inside and outside and the food is not wetted.

Owner:PANASONIC CORP

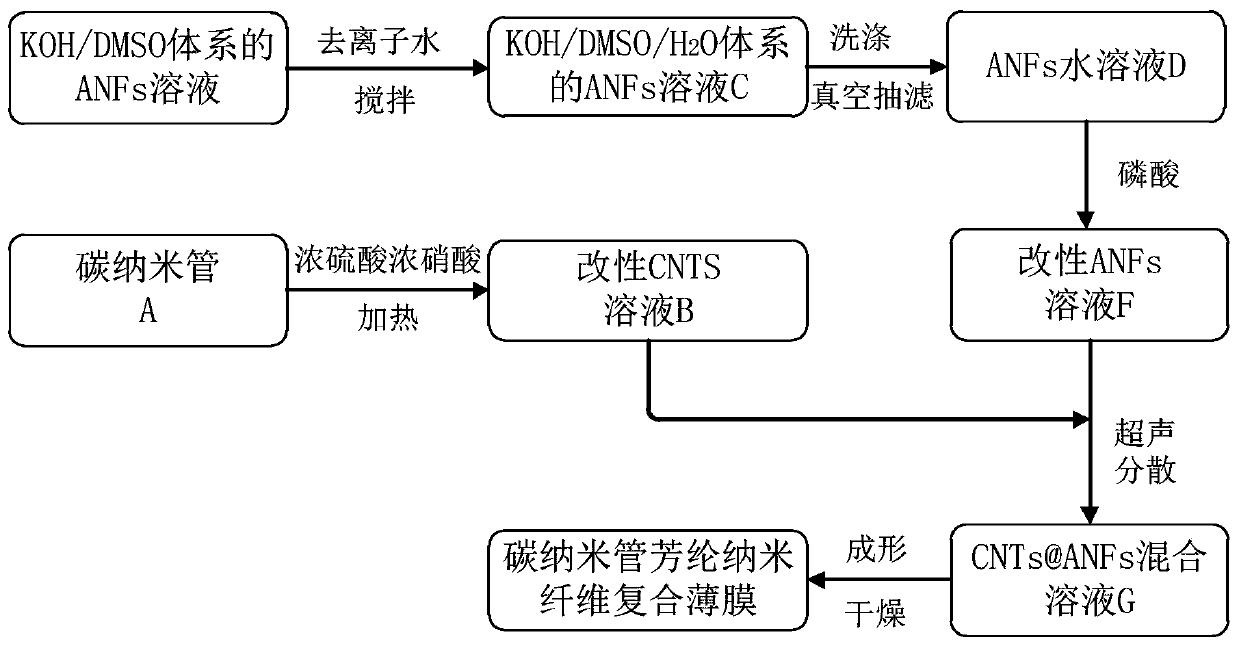

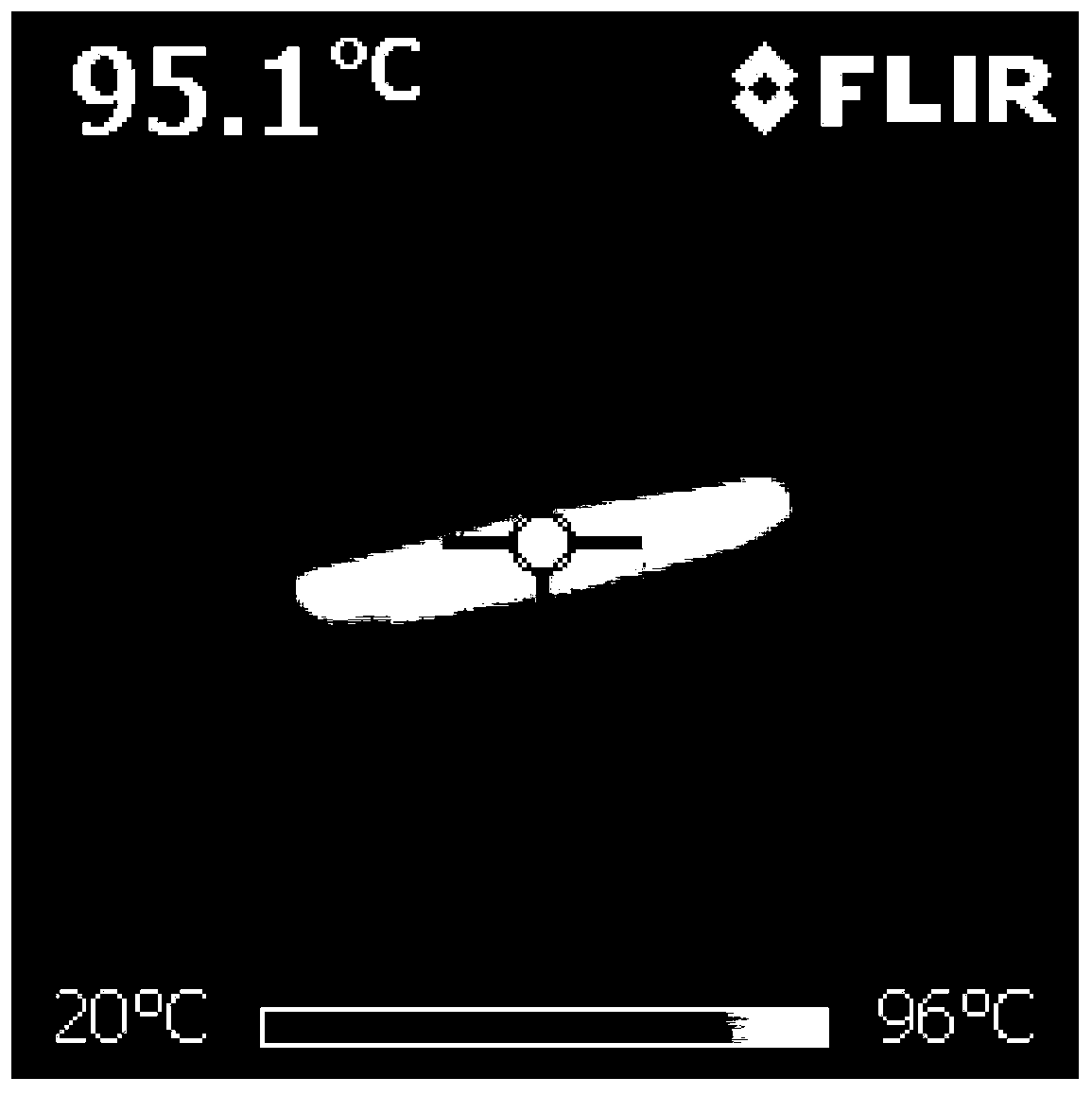

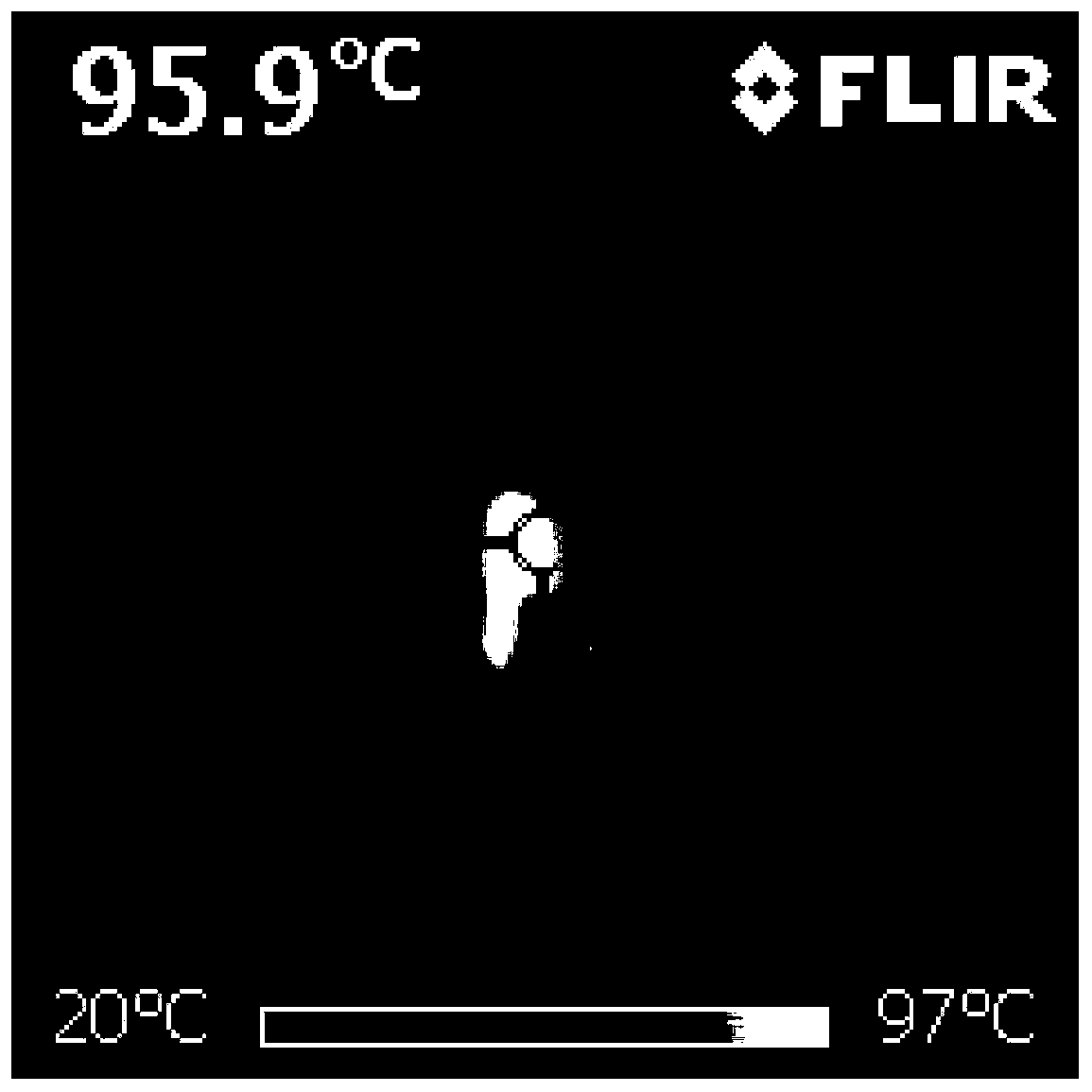

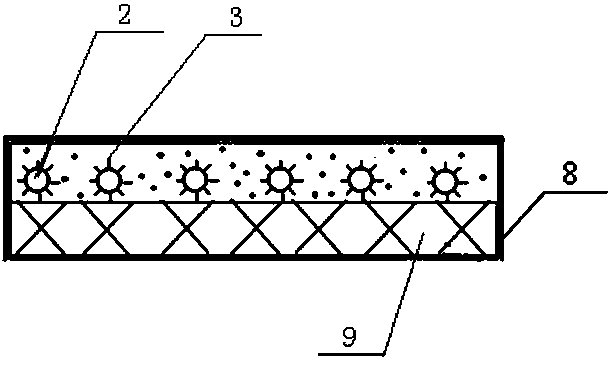

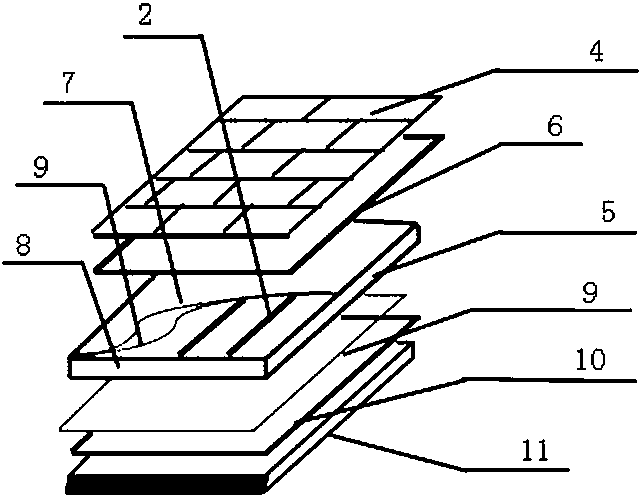

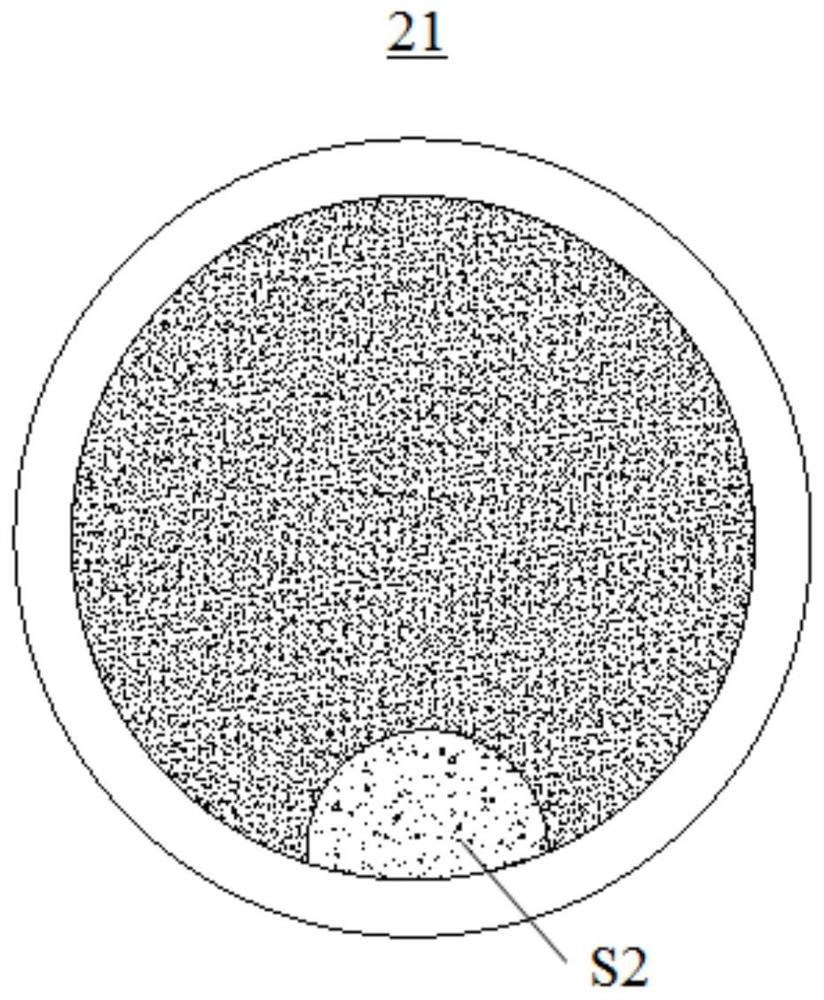

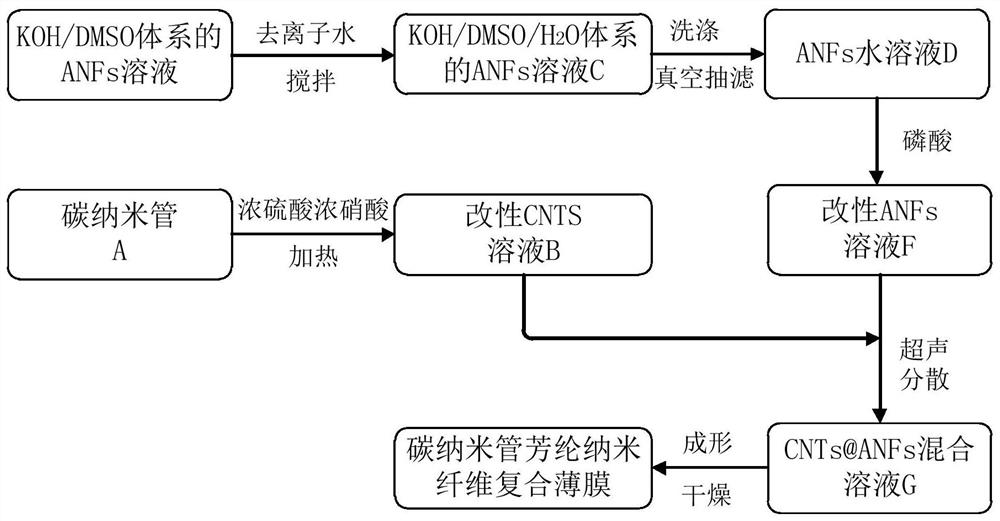

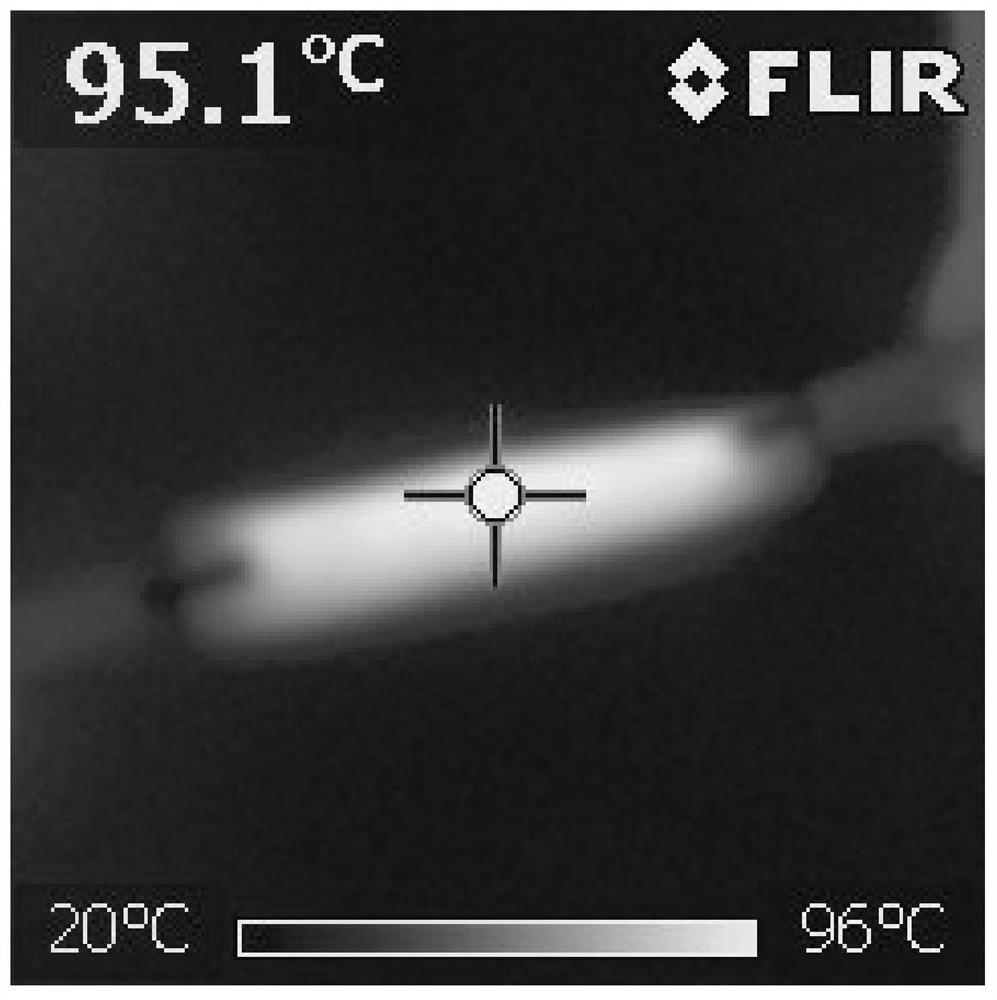

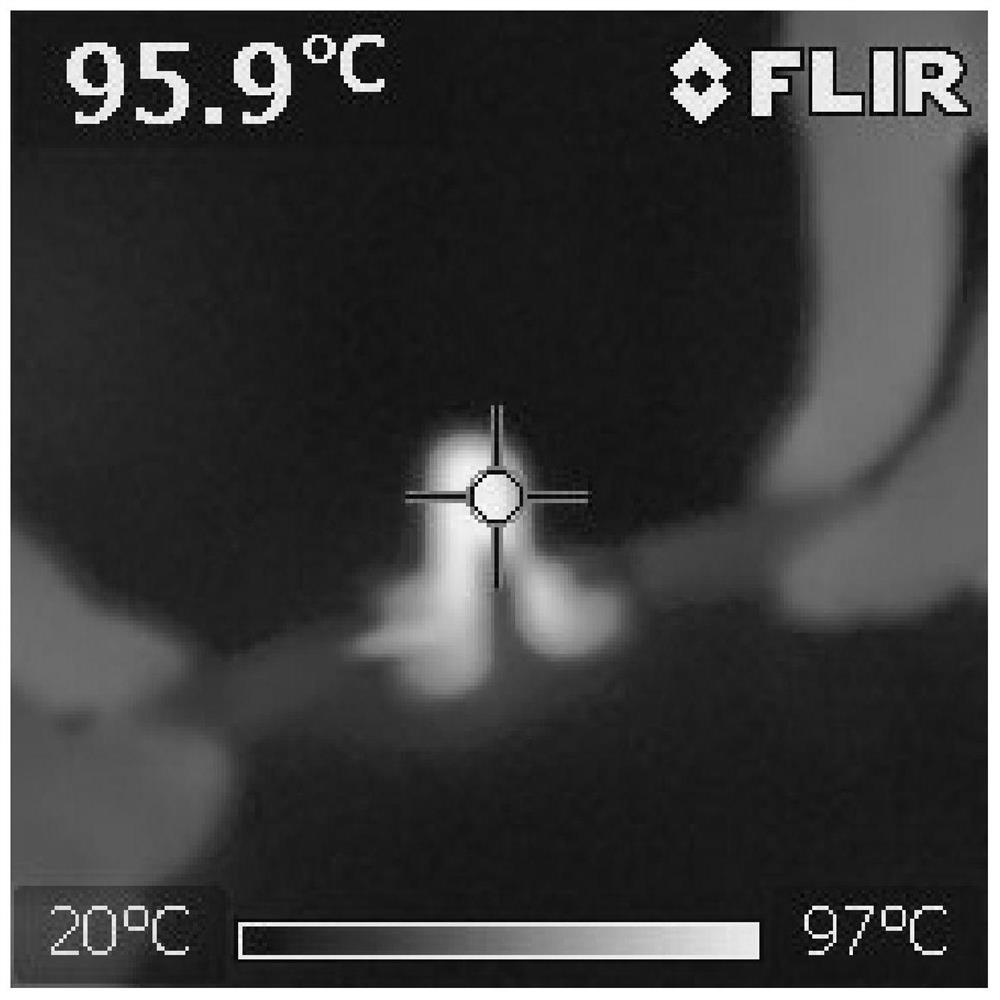

Flexible far infrared heating aramid nano-fiber thin film and preparation method

ActiveCN109763374AEvenly heatedNo hair lossCellulosic pulp after-treatmentNon-fibrous pulp additionScale structureCarbon nanotube

The invention discloses a flexible far infrared heating aramid nano-fiber thin film and a preparation method. The flexible far infrared heating aramid nano-fiber thin film is prepared by uniformly dispersing carbon nanotubes with a nano-scale structure and excellent mechanical properties and electric properties and aramid nano-fibers with excellent mechanical properties, and the film forming performance of the aramid nano-fibers and the advantages that a strong network crosslinking structure is easily generated by abundant functional groups on the surfaces of the aramid nano-fibers are sufficiently expressed; the dispersion performance and film forming performance of the carbon nanotubes are cooperatively improved and an aramid nanocellulose based novel material with flexibility, conductivity and low-temperature far infrared heating performance is developed; the problems of a current flexible heating material that the surface is not uniformly heated, the temperature different is too great, the heating performance is not stable and the service life is relatively low are improved, and the product grade is improved; and the flexible far infrared heating aramid nano-fiber thin film canmeet the requirements of application to electric heating physiotherapy functional clothing, intelligent physiotherapy safety clothing, medical far infrared therapy chambers and the like.

Owner:SHAANXI UNIV OF SCI & TECH

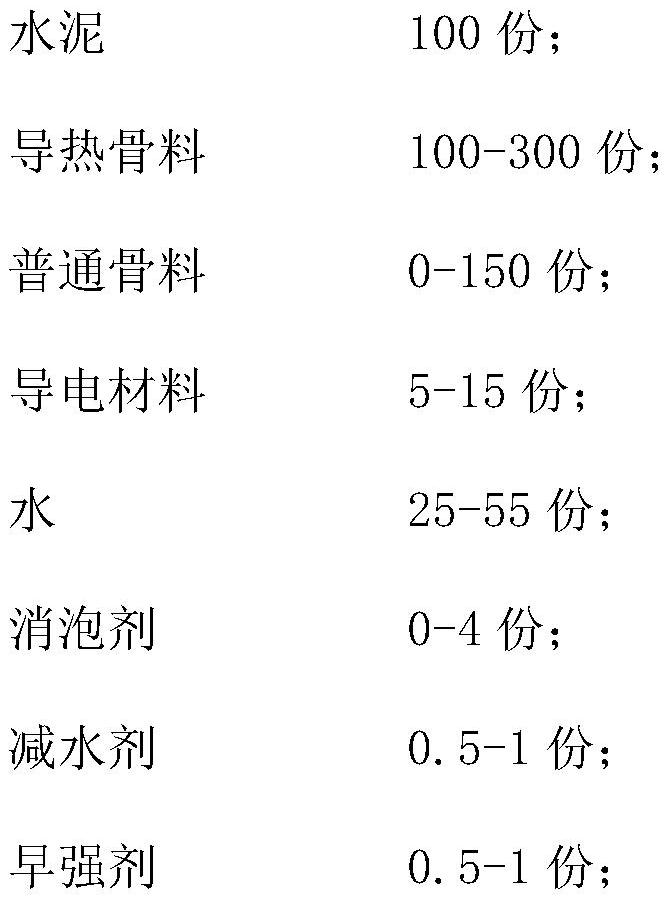

Electric heating concrete plate for heating and preparation method thereof

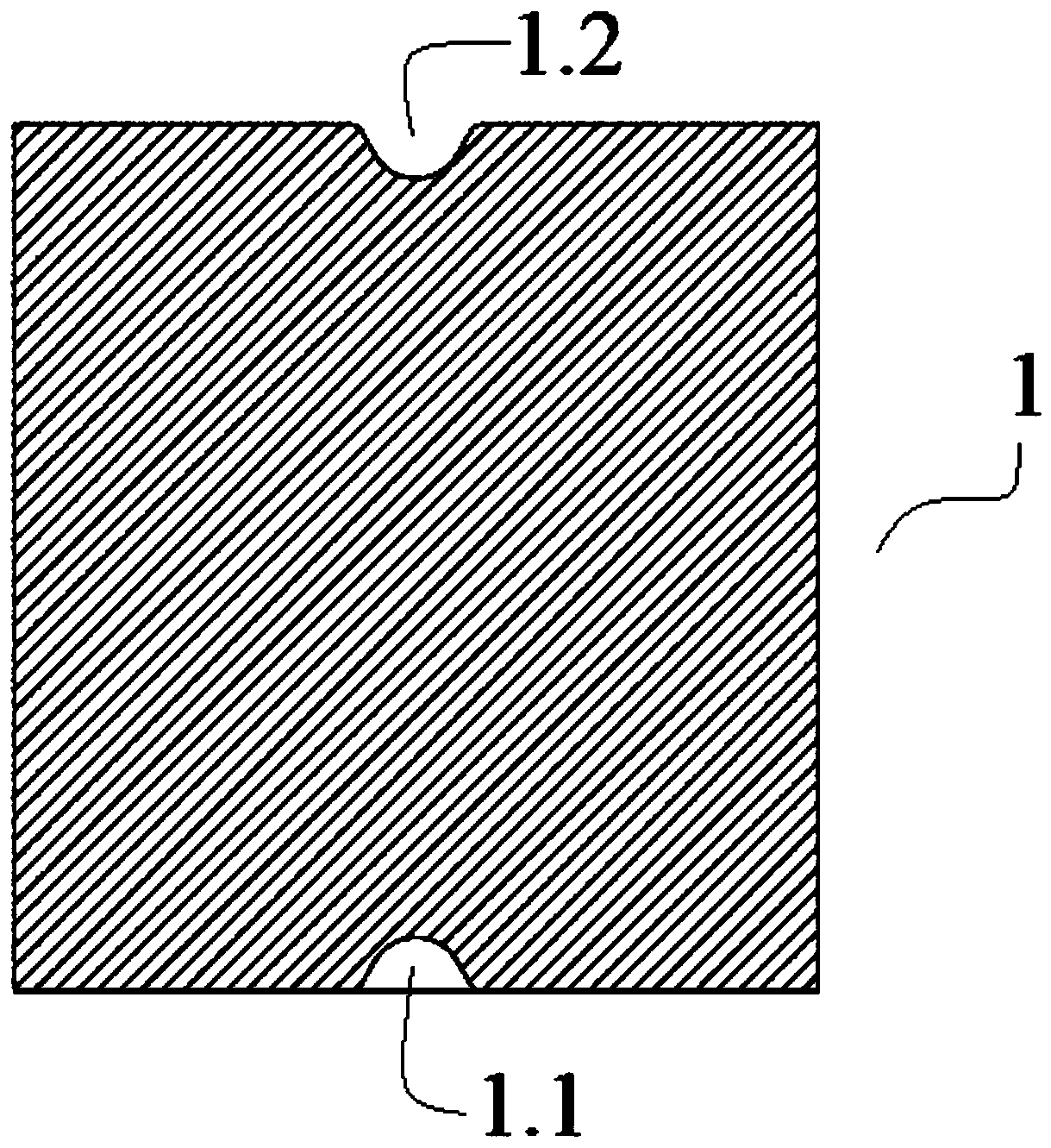

The invention discloses an electric heating concrete plate for heating. The electric heating concrete plate is prepared from the following raw materials in parts by weight: 100 parts of cement, 100-300 parts of heat-conducting aggregate, 0-150 parts of common aggregate, 5-15 parts of a conductive material, 25-55 parts of water, 0-4 parts of a defoaming agent, 0.5-1 part of a water reducing agent and 0.5-1 part of an early strength agent, wherein the early strength agent is at least one selected from calcium acetate and calcium formate. The heat-conducting aggregate is added into the electric heating concrete plate, so the heat-conducting property of the electric heating concrete plate is improved, and the condition of uneven heating of the plate can be improved; and calcium acetate and calcium formate are used as the early strength agent, so the early strength of the poured electric heating plate can be improved, and the resistivity of the plate can be reduced to a certain extent, thereby reducing the consumption of the conductive material and lowering production cost.

Owner:王瑞

Positive plate, negative plate, battery cell, lithium battery and preparation method of lithium battery

InactiveCN110224109ALarge capacityHigh compacted areal densityFinal product manufactureNon-aqueous electrolyte accumulator electrodesLithium-ion batteryBattery capacity

The invention discloses a positive plate, a negative plate, a battery cell, a lithium battery and a preparation method of the lithium battery, and belongs to the technical field of batteries. Positiveand negative tabs on the positive and negative plates belong to embedded tabs; on the premise that the shape and size of the battery are kept the same, the mass energy density of the embedded tabs ishigher than that of the extended tabs; meanwhile, due to the fact that an area ratio of the positive and negative tabs is low, the internal space utilization rate of the battery is high, and the advantages of high compaction surface density of the positive and negative plates and larger battery capacity are achieved; and the positive and negative tabs are positioned at the two ends of the positive and negative plates respectively, so that the problem of non-uniform heating in the charging and discharging processes of the lithium battery can be effectively improved, and the safety and reliability of the lithium battery are improved.

Owner:湖北锂诺新能源科技有限公司

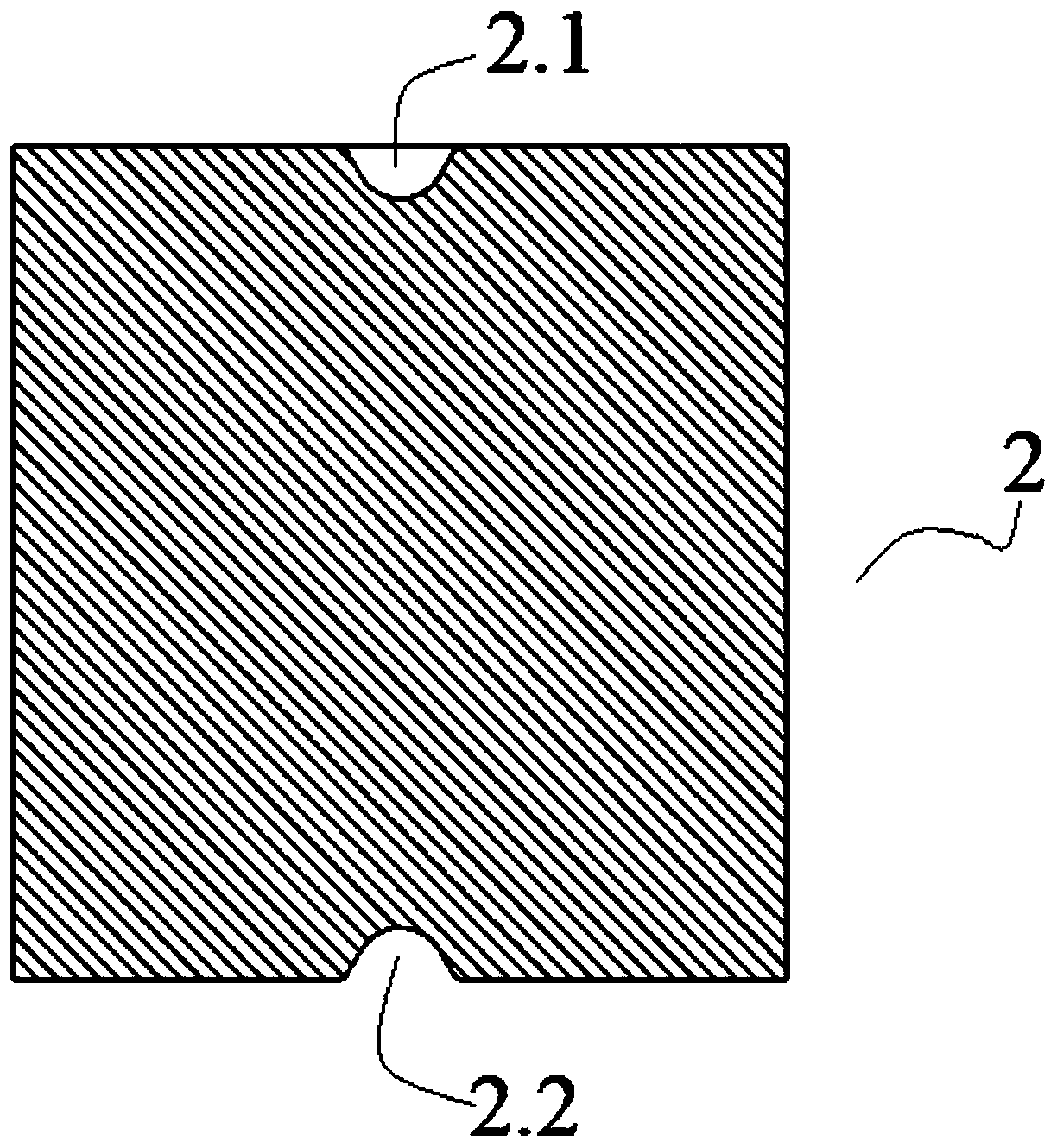

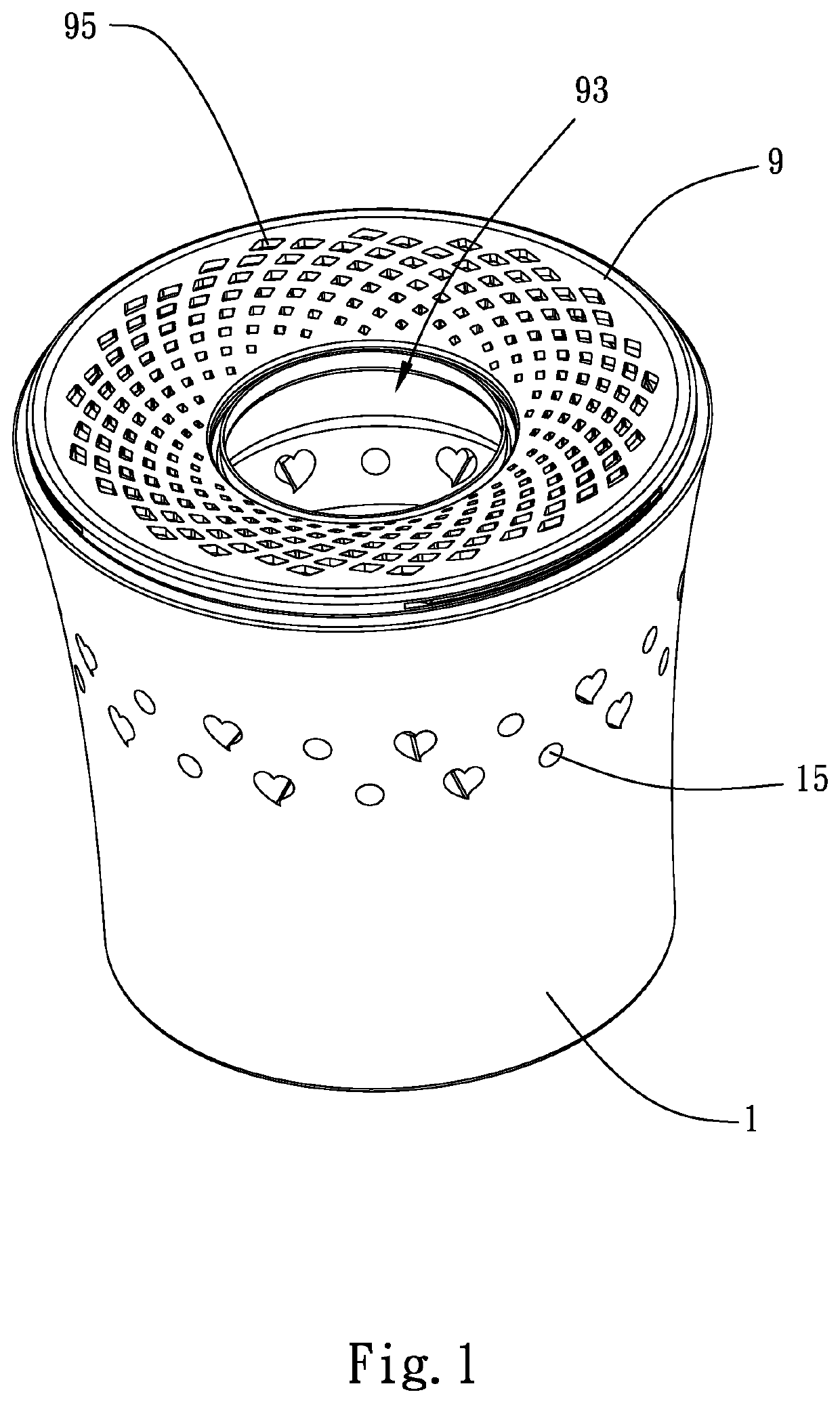

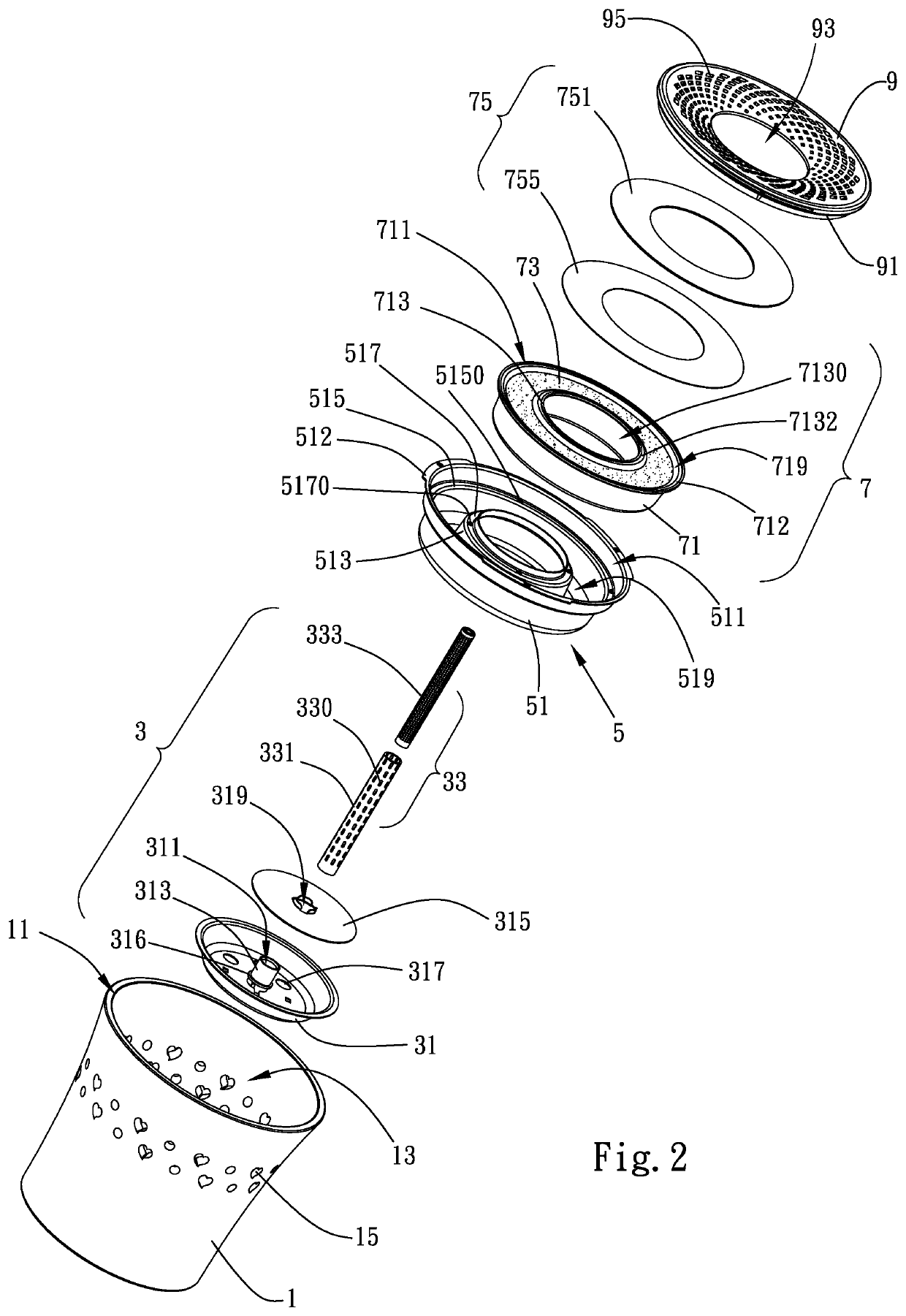

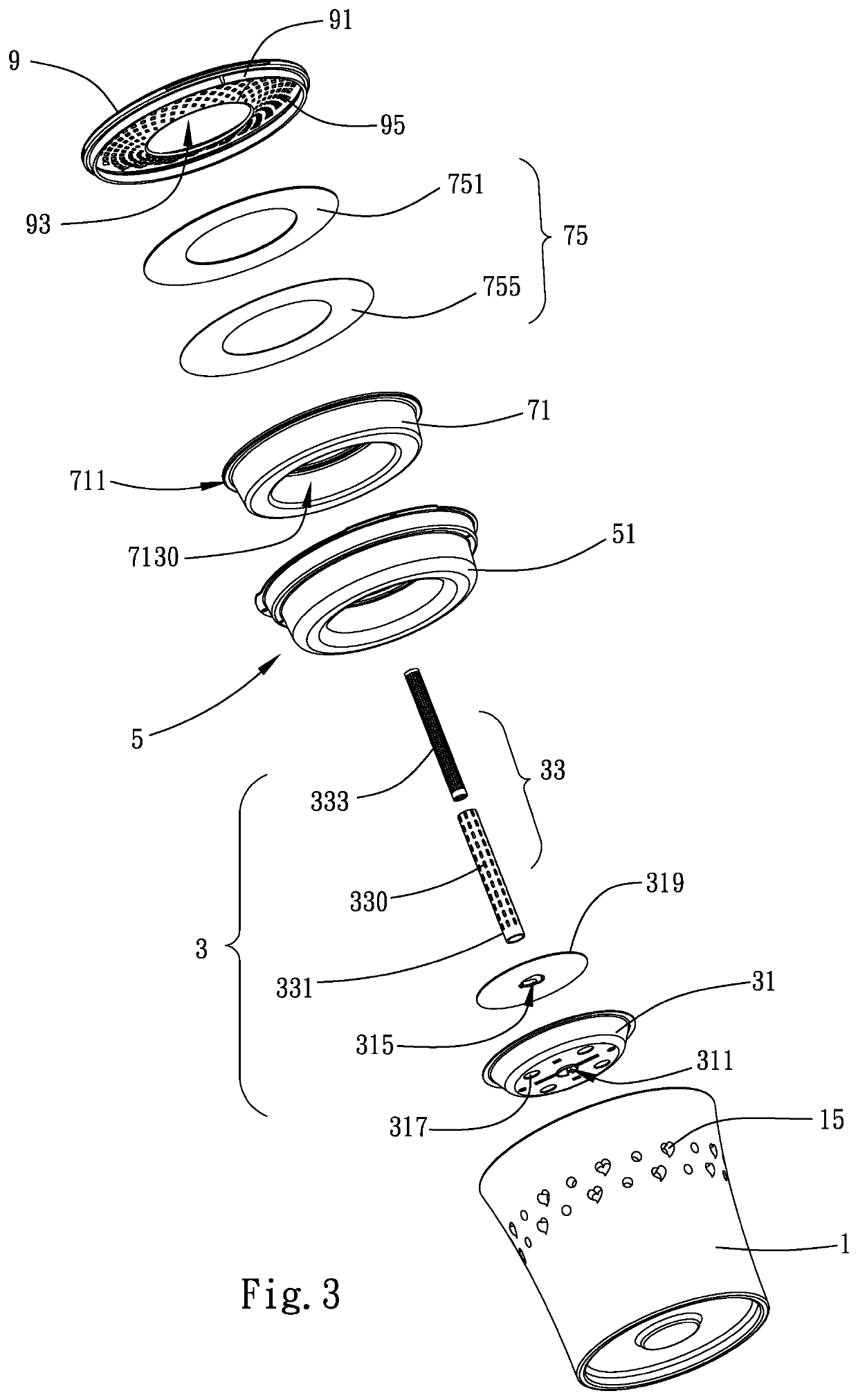

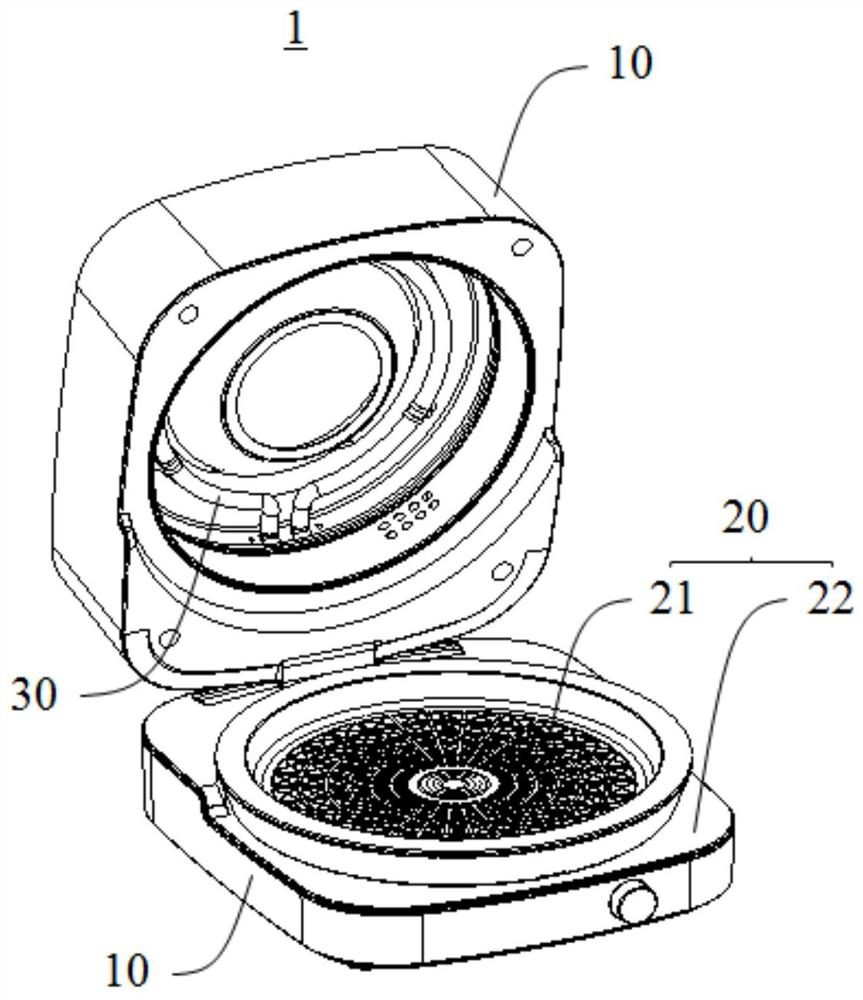

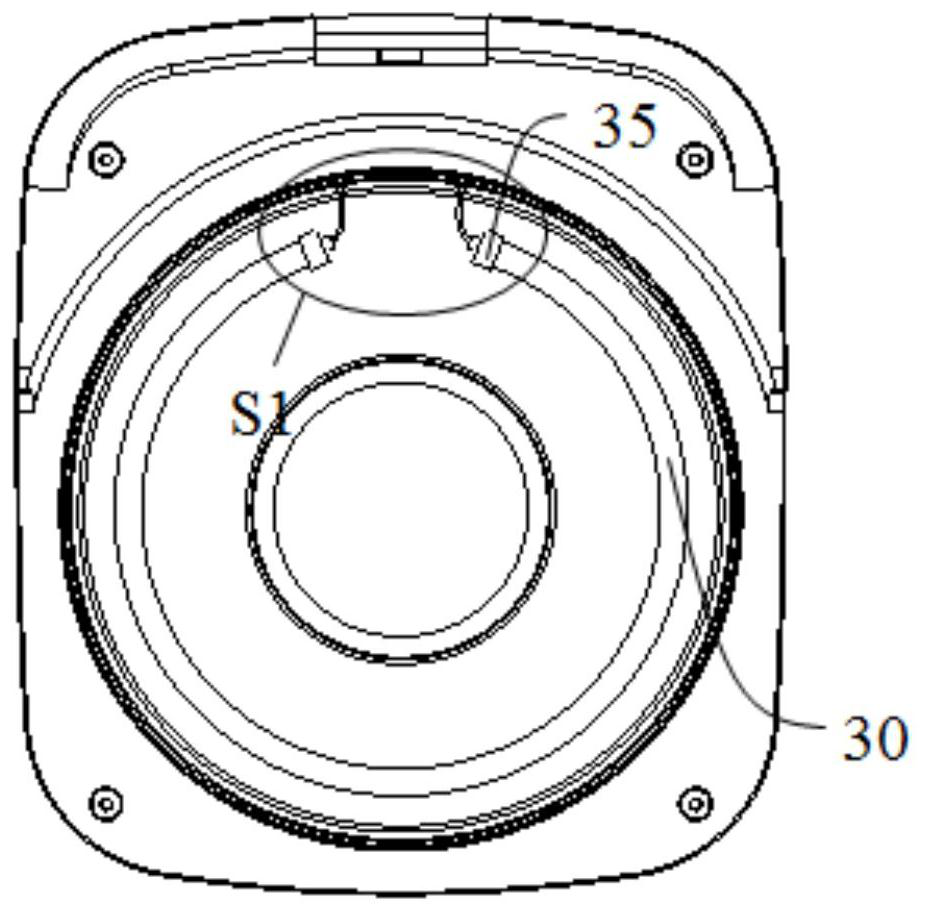

Aroma diffuser using fragrance capsule

InactiveUS20200171191A1Good breathabilitySafe to useGaseous substancesComposite materialThermal emission

An aroma diffuser includes a housing, a burner, a thermal conducting device and a hollow annular fragrance capsule. The burner and the thermal conducting device are combined in the housing. The thermal radiation of the thermal conducting device can be continuously and effectively transmitted to the donut-shaped fragrance capsule and the fragrance substance to quickly produce a stable aroma. The fragrance capsule is provided with a breathable film that prevents the fragrance substance from flowing to the outside of the fragrance capsule to contaminate the burner or the surroundings. The breathable film is formed of a fixing film and a microporous film. The fixing film combined with the microporous film is not deformed or ugly when heated, and the aroma can be diffused outward from the breathable film. The fragrance substance can be quickly replaced with another fragrance capsule after use.

Owner:DONGGUAN YIH TEH ELECTRIC PRODS

Novel Pt-Co/NC catalyst and preparation method and application thereof

PendingCN111987322AGood thermal conductivity and electron transportImprove the problem of uneven metal heatingCell electrodesDoped carbonPrecious metal

The invention relates to a novel Pt-Co / NC catalyst and a preparation method and application thereof. In the Pt-Co / NC catalyst, nitrogen-doped carbon is used as a carrier, metal Co (cobalt) is used asa cocatalyst, and precious metal Pt (platinum) is used as a main catalyst. In a fuel cell, a catalyst in a membrane electrode is easily in contact with a reactant oxygen, and the ORR activity and durability are improved under the synergistic catalytic action of platinum-cobalt. Main active components of the catalyst are Pt and Co, the catalyst is prepared by means of coprecipitation, high-temperature roasting, solvent evaporation and the like, and the preparation method is simple and convenient to operate. According to the Pt-Co / NC catalyst, porous carbon NC obtained after acid etching provides a very good loading surface and pore channels for metal particles, and platinum metal can be uniformly distributed. Nitrogen-doped carbon can activate ORR (oxygen reduction) reaction, indirectly plays a role in replacing rare precious metal platinum, is beneficial to manufacturing low-price fuel cells with low manufacturing environment load, and is more beneficial to promoting global energy distribution and development under the condition of not being controlled by resources.

Owner:广东能创科技有限公司

Preparation method of graphene foam

The invention discloses a preparation method of graphene foam. The preparation method comprises the following steps: firstly, graphene derivative foam is prepared from a graphene derivative solution; then the graphene derivative foam passes through a microwave heating region at a set speed in a set atmosphere, and the graphene derivative foam is heated to convert graphene derivatives into graphene which is cooled to obtain the graphene foam. The method provided by the invention solves problems of high energy consumption, low yield and graphene derivative foam performance requiring to be improved due to the existing graphene foam needs high temperature vapor deposition, realizes convenient, fast and mass production of the graphene foam material, and is expected to contribute to further development and application of graphene and foam materials.

Owner:SOUTHEAST UNIV

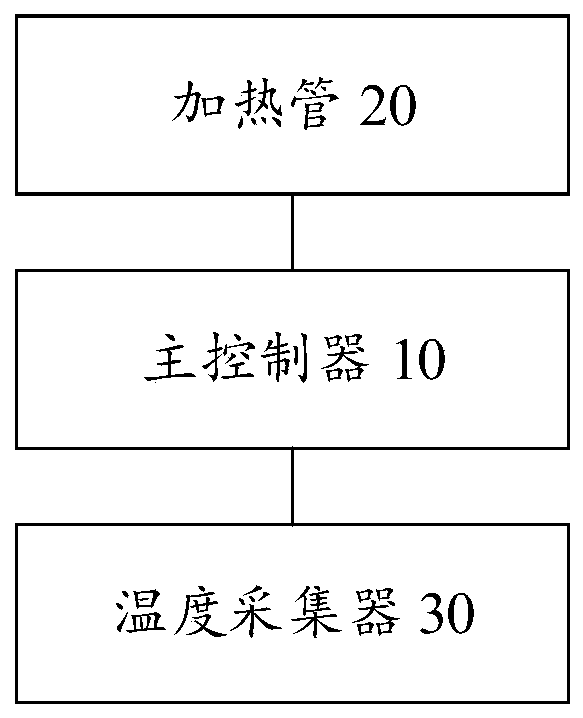

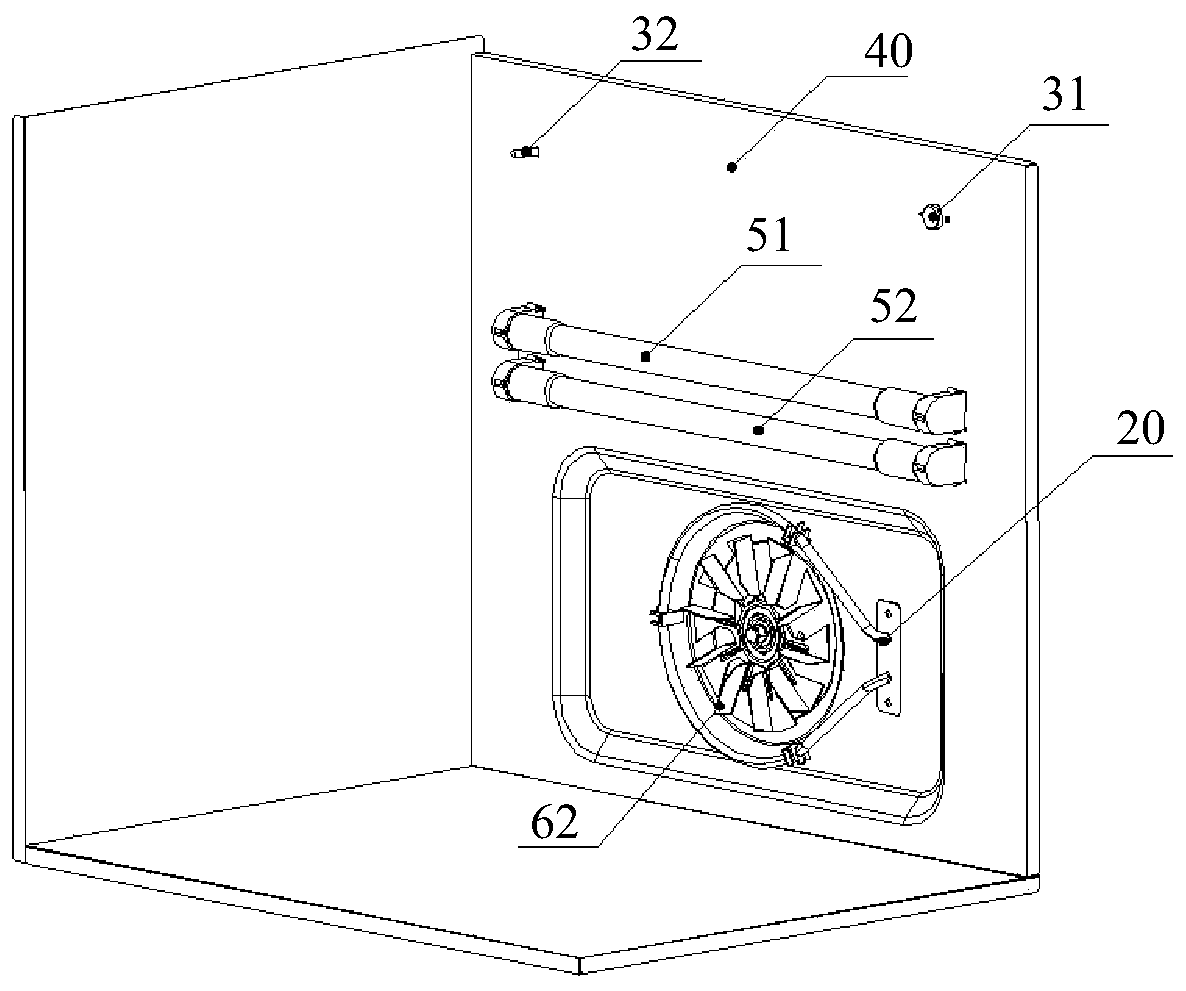

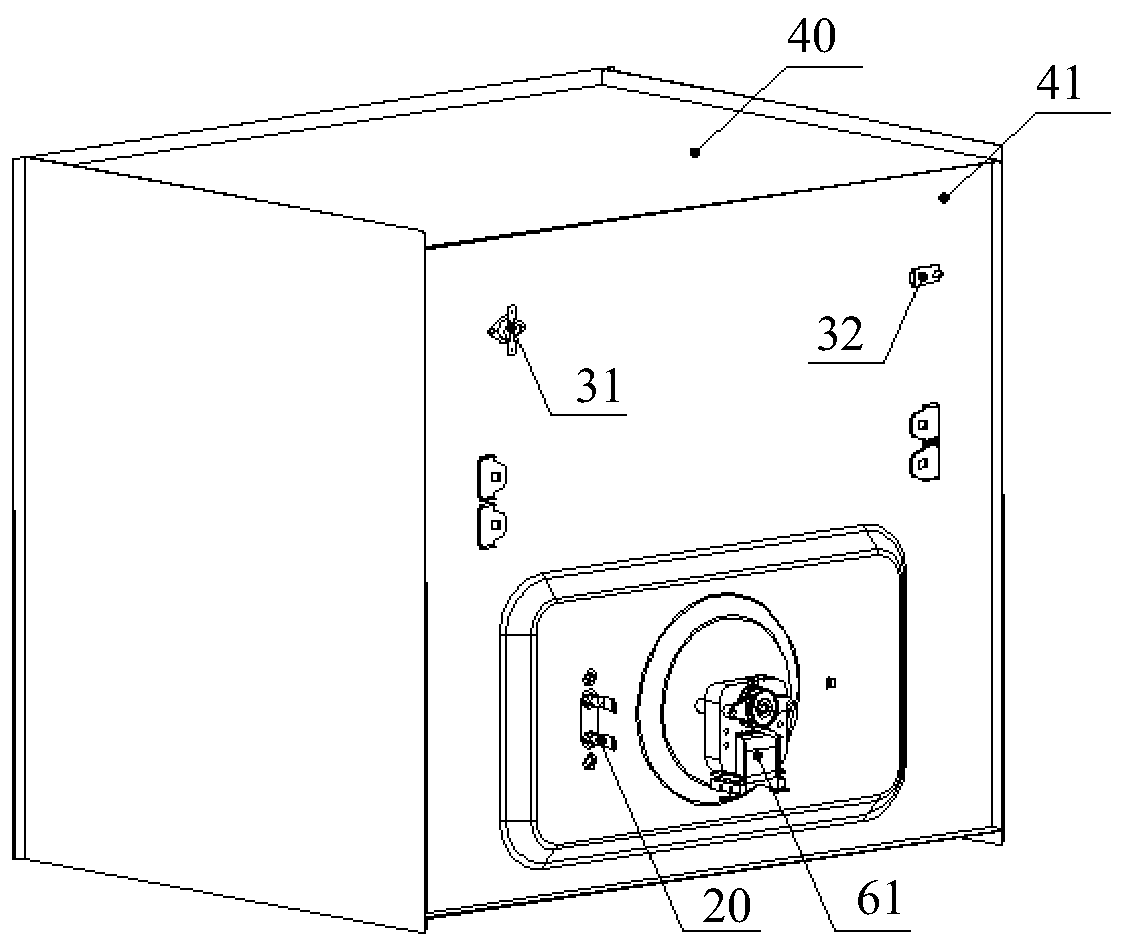

Disinfection cabinet and control method of disinfection cabinet

InactiveCN110075327AImprove uneven heatingKeep dryKitchenware cleanersLavatory sanitoryTemperature controlEngineering

The invention provides a disinfection cabinet and a control method of the disinfection cabinet, and relates to the technical field of disinfection cabinets. The disinfection cabinet comprises a cavity, wherein a heating pipe and a temperature collector are arranged in the cavity and are respectively connected with a main controller; the main controller is used for receiving mode setting information inputted by a user, tableware surface temperature and the temperature in the cavity collected by the temperature sensor, and is used for driving the heating pipe to run according to the mode settinginformation, the tableware surface temperature and the temperature in the cavity. The control method comprises the following steps of receiving the mode setting information inputted by the user; according to the mode setting information, enabling the temperature collector to collect the tableware surface temperature and the temperature in the cavity at a preset collecting interval; according to the tableware surface temperature and the temperature in the cavity, controlling the working state of the heating pipe. The disinfection cabinet and the control method of disinfection cabinet have theadvantages that the problem of nonuniform heating of the tableware surface temperature in the cavity can be improved, and the tableware drying effect is improved.

Owner:HANGZHOU ROBAM APPLIANCES CO LTD

Preparation method of graphene inorganic nonmetal composite material

The invention discloses a preparation method of a graphene inorganic nonmetal composite material. The preparation method comprises the following steps of enabling a graphene derivative to be dispersed in a solvent for the first time to be mixed with solid granules so as to obtain a mixture; drying the mixture, after the mixture is dried, performing heating treatment on the mixture at the set speed under set atmosphere through a microwave heating region, so as to convert a graphene derivative in the mixture into graphene, and then performing cooling so as to obtain a mixture of graphene and granular substances; and enabling the mixture to be compounded with inorganic nonmetal in methods of melting, high-temperature sintering, extruding, shaping and the like so as to obtain the graphene-inorganic nonmetal composite material. The method provided by the invention solves the problem that conventional graphene is difficult to disperse and the graphene derivative is poor in properties, can be used for convenient and quick batch production of the graphene-inorganic nonmetal composite material, and is hopeful to make contributions to further development and application of the graphene and inorganic nonmetal materials.

Owner:SOUTHEAST UNIV

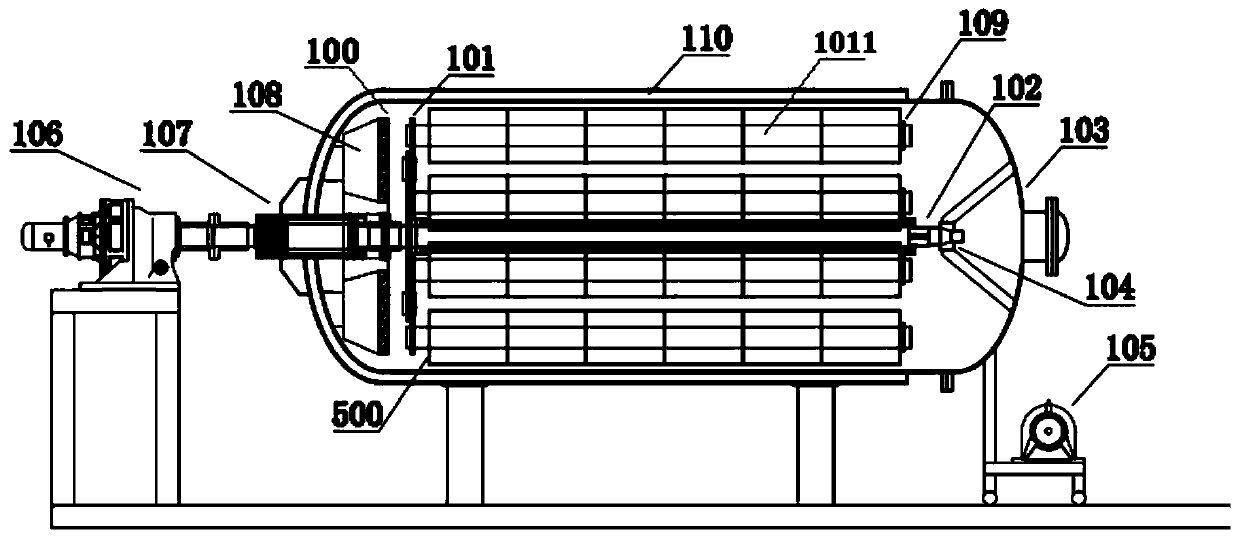

Fiber heat treatment reaction device, heat treatment system and heat treatment method

PendingCN111364109AEasy to realize industrializationPrevent oxidationArtificial thread manufacturing machinesFilament manufactureFiberThermodynamics

The invention discloses a fiber heat treatment device. The fiber heat treatment device comprises a reaction kettle body, a center shaft, a tow bearing device and a gas spraying device are arranged inthe reaction kettle body, wherein the tow bearing device is arranged on the center shaft and used for containing package fibers, and the central shaft is connected with an external driving mechanism.The invention further provides a fiber heat treatment system and a heat treatment method. According to the heat treatment reaction device, the whole roll of package fibers are placed on the tow bearing device, the space utilization rate of the heat treatment reaction device is increased, the heat treatment yield and the heat treatment efficiency are improved, and industrialization of fiber heat treatment is conveniently achieved; and meanwhile, the driving mechanism drives the center shaft to rotate so as to drive the whole roll of package fibers to rotate in the heat treatment process, the gas spraying device inputs inert gas into the heat treatment reaction device, the package fibers make full contact with the inert gas atmosphere, and small molecules separated out of the surfaces of thefibers due to the heat treatment reaction are blown away and brought away, so that heat treatment efficiency is improved.

Owner:宁波海格拉新材料科技有限公司

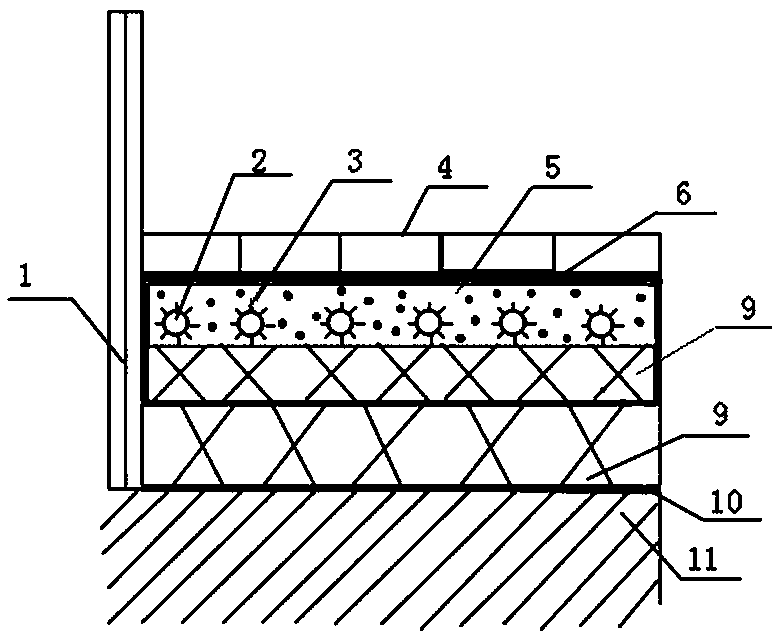

Fin type pulsating heat pipe phase change energy storage integrated module and application

InactiveCN108386899AImproved thermal inertiaLower water supply temperatureSolar heating energyHeat storage plantsInsulation layerEnhanced heat transfer

The invention relates to a fin type pulsating heat pipe phase change energy storage integrated module and application. The fin type pulsating heat pipe phase change energy storage integrated module comprises a steel plate box which is formed by stainless steel plates, the lower layer of the steel plate box is paved with a polyurethane insulation layer, a plurality of sets of pulsating heat pipes are arranged in the steel plate box, fins for enhanced heat transfer are fully distributed on the pulsating heat pipes, the steel plate box is filled with a phase change energy storage material, and the upper end of the steel plate box is sealed with an aluminum plate. According to the fin type pulsating heat pipe phase change energy storage integrated module and application, the thermal inertia ofa radiator arranged at the tail end is perfected, the water supply temperature required by a heating system is reduced, efficient and multiple utilization of energy sources in building heat supply isachieved, and the problem that at present, the environment is polluted by country fire coal heating in cold regions is solved.

Owner:NORTHEAST GASOLINEEUM UNIV

Insecticidal and bactericidal method for nut roasted food

InactiveCN112690331ANo change in flavorEfficient killingFood freezingFood thermal treatmentBiotechnologyMicroorganism

The invention discloses an insecticidal and bactericidal method for nut roasted food and relates to the technical field of nut processing. The method comprises the following steps: airing and selecting harvested nut raw materials, freezing, and carrying out insecticidal and bactericidal treatment on the frozen nut raw materials by microwave heating. Before adopting insecticidal and bactericidal treatment by microwave heating, nut raw materials are frozen firstly, so that the problem of heating nonuniformity in the microwave heating process is solved, then microorganisms, worm eggs and other diseases and insect pests in nut fruits are effectively killed, and the killing effect is good; and freezing and microwave heating are combined for insecticidal and bactericidal treatment, so that the microwave treatment time is shortened, and the problems of product discoloration and the like are avoided.

Owner:WUHU FEIYUE FOOD

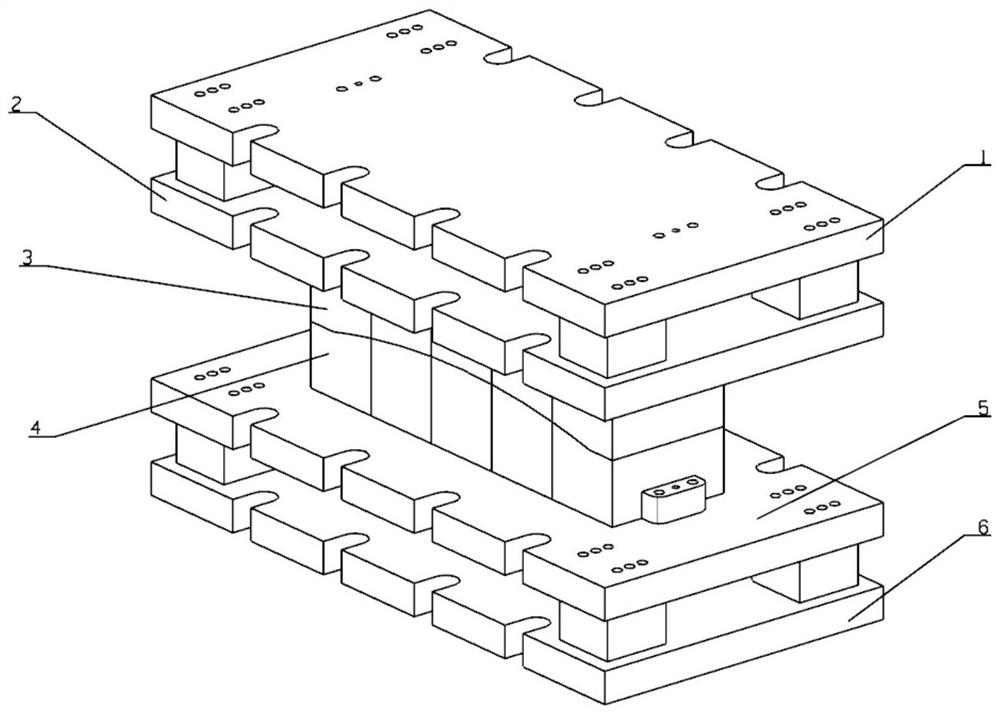

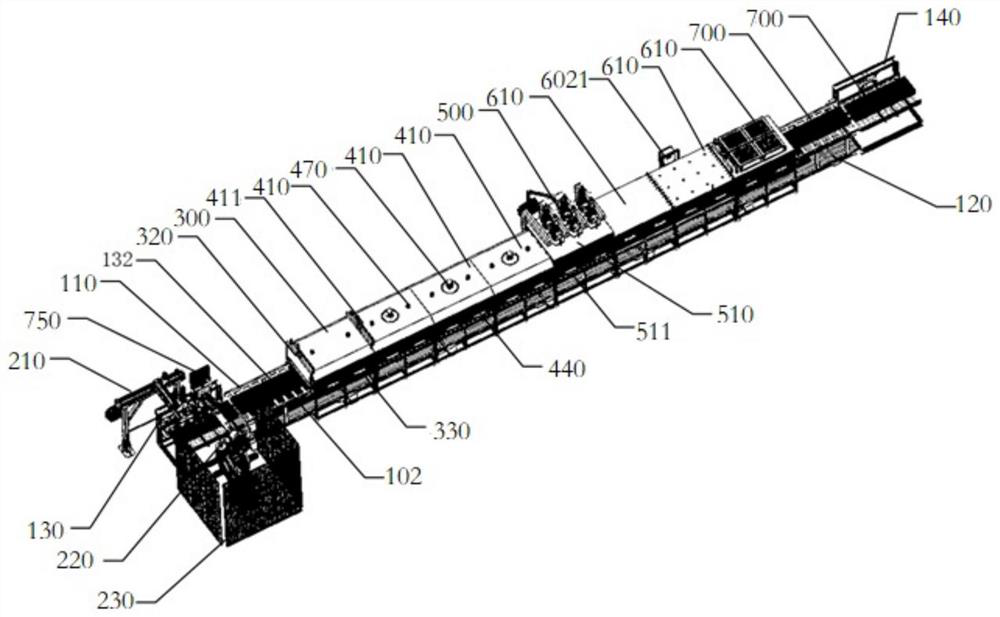

Conformal water-cooling mold for indirect thermal forming production line

PendingCN113182436AImprove material performanceEasy to controlShaping toolsVehicle componentsProduction lineThermodynamics

The invention discloses a conformal water-cooling mold for an indirect thermal forming production line, and belongs to the technical field of thermal forming modules. The conformal water-cooling mold for the indirect thermal forming production line comprises an upper mold bottom plate and a lower mold bottom plate, an upper mold mounting plate is fixedly connected to the bottom surface of the upper mold bottom plate, and a thermal forming upper mold is connected to the bottom surface of the upper mold mounting plate; a lower die mounting plate is fixedly connected to the top surface of the lower mold bottom plate, and a thermal forming lower mold is connected to the top surface of the lower mold mounting plate; a mounting cavity is formed between the bottom plate and the mounting plate, and a cooling water connecting device is mounted in the mounting cavity. The problems that an existing design structure is fixed and cannot be suitable for manufacturing work of automobile parts with complex profiles, and a water cooling structure mostly adopts a straight pipeline and cannot be attached to a complex transverse plane, so that local temperature distribution is unbalanced, the cooling effect is poor, and the temperature of a fillet part is too high are effectively solved.

Owner:HEFEI METALFORMING MACHINE TOOL

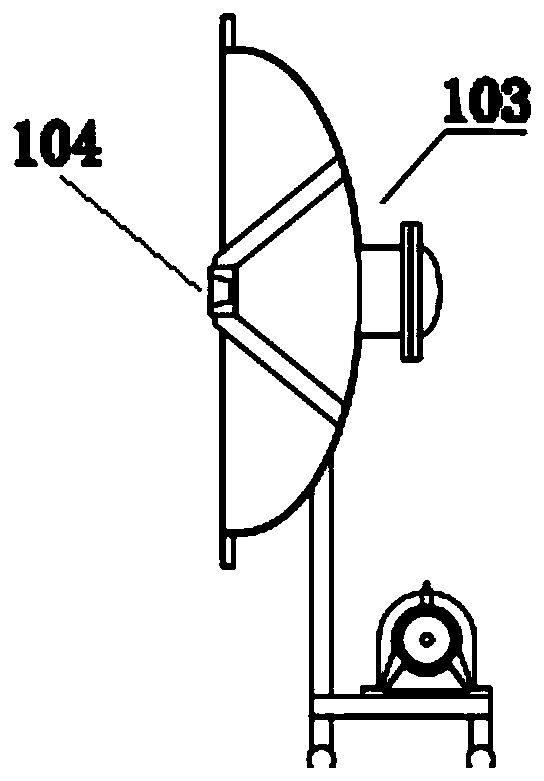

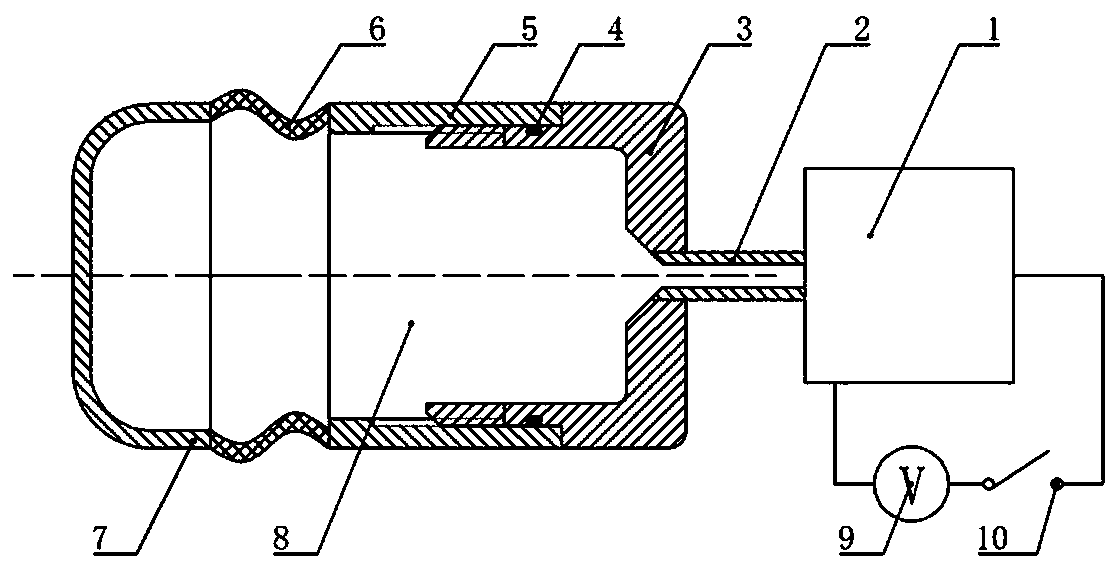

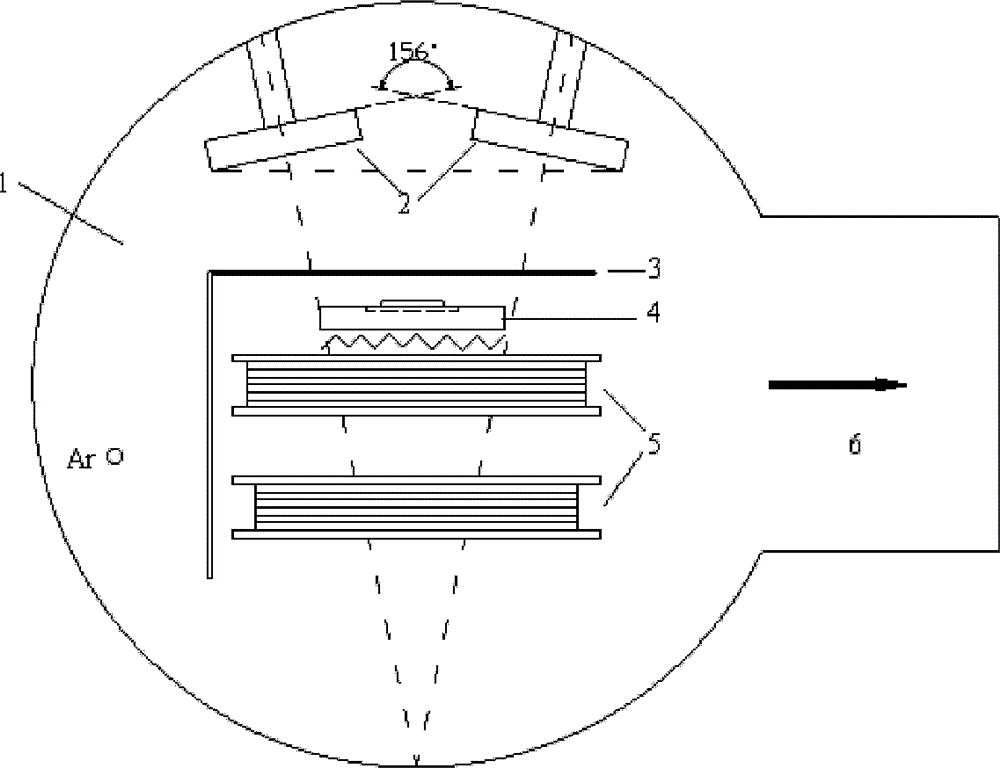

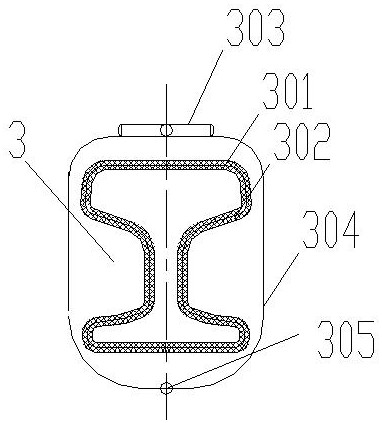

Phase-change buoyancy engine based on microwave heating

InactiveCN109795655AHeating evenlyImprove uneven heatingUnderwater vesselsUnderwater equipmentTemperature controlState of art

The invention discloses a phase-change buoyancy engine based on microwave heating. The phase-change buoyancy engine comprises a buoyancy generating unit and a temperature control unit. The buoyancy generating unit comprises a clamp, a sealing ring, a casing, a heat insulating material, a phase change material, a base and a watertight connector. The temperature control unit comprises a magnetron, afilter conduit, a metal reflector, a metal heat-radiating plate, a power supply and a switch. The phase-change buoyancy engine has the advantages that a microwave heating device is used for rapid anduniform heating, and accordingly, the problem that phase change materials in the prior art are heated slowly and unevenly is solved.

Owner:余姚市浙江大学机器人研究中心 +1

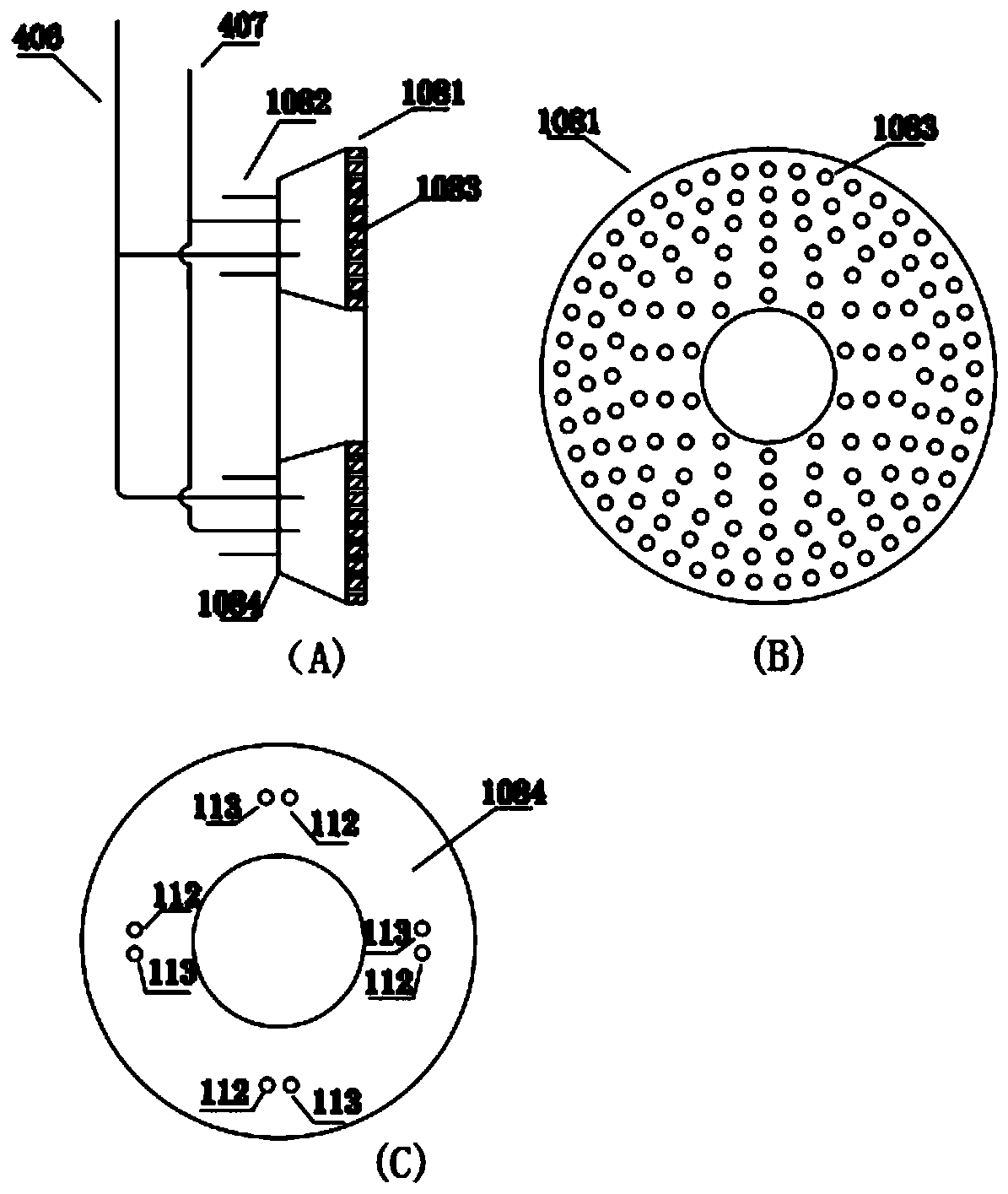

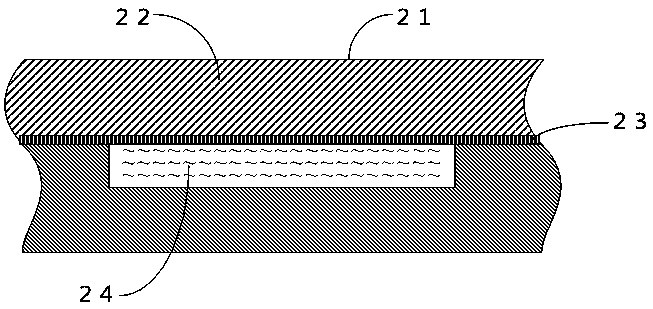

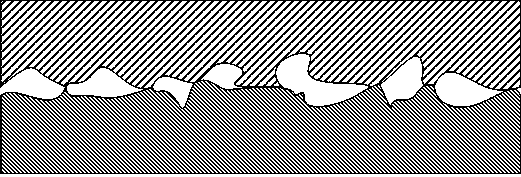

Vacuum plating cathode target using foam metal for enhancing cooling effect

PendingCN108130516AImprove uneven heatingDiffusion fastVacuum evaporation coatingSputtering coatingCooling effectGraphite

The invention relates to a vacuum plating cathode target using foam metal for enhancing a cooling effect. The vacuum plating cathode target comprises a magnet yoke, a magnetic body, a target material,a backboard, a graphite flake, the foam metal and a cooling liquid flow channel. The graphite flake arranged between the target material and the backboard is used for decreasing the thermal contact resistance, the foam metal which is tightly connected to the other surface of the backboard and is further filled into the cooling liquid flow channel is used for increasing the heat exchange area, andthe cooling effect is enhanced.

Owner:WUZHOU HGP ADVANCED MATERIALS TECH CORP

Glass hot bending forming device and method

ActiveCN113233743AImprove yieldReduce labor costsGlass reforming apparatusGlass productionMolding machineProcess engineering

The invention discloses a glass hot bending forming device and method. The device comprises a conveying mechanism, a feeding and discharging mechanism, a preheating mechanism, a forming mechanism and a cooling mechanism, the conveying mechanism comprises a production conveying module and a backflow conveying module, and the production conveying module sequentially penetrates through the preheating mechanism, the forming mechanism and the cooling mechanism; and the backflow conveying module is used for conveying glass finished products in the mold to the feeding and discharging mechanism in a backflow mode for material taking operation, the production conveying module comprises a first conveying frame, the backflow conveying module comprises a second conveying frame, and the first conveying frame and the second conveying frame are each provided with a plurality of first rollers at intervals. A to-be-processed glass blank is transferred into the mold through the feeding and discharging mechanism, so that the mold is respectively transferred to the preheating mechanism, the forming mechanism and the cooling mechanism under the driving of the conveying mechanism to be processed to prepare a glass finished product, and then the glass finished product in the mold is returned and conveyed to the feeding and discharging mechanism for material taking operation; therefore, whole-course automatic operation is achieved, and machining efficiency is improved.

Owner:GUANGDONG HUST IND TECH RES INST

Microwave heating apparatus and method

InactiveCN1175209CEasy to produceQuality declineDomestic stoves or rangesLighting and heating apparatusMicrowaveProcess engineering

An object such as food is heated favorably by means of microwaves while enclosing the food with superheated steam. The apparatus comprises a heating chamber in which an object to be heated is put, steam generating means for supplying superheated steam to the heating chamber, superheated steam maintaining means provided in the heating chamber to prevent the temperature of the superheated steam in the heating chamber from lowering, and microwave generating means for irradiating the object with microwaves. The object placed in the heating chamber is heated in superheated steam with microwaves, so that the food is efficiently heated from inside and outside and the food is not wetted.

Owner:PANASONIC CORP

Cooking device

PendingCN114680649AReduce temperature differenceImprove uneven heatingBaking vesselsRoasters/grillsEngineeringHome appliance

The invention provides a cooking device, and relates to the technical field of household appliances. According to the cooking device, a shell is provided with a hollow cooking cavity used for containing food, and the height of the cooking cavity is smaller than a preset value; the baking tray assembly is fixedly connected with the shell, is arranged below the cooking cavity, is adjacent to the cooking cavity and is used for bearing food; the light wave tube is connected with the shell and arranged above the cooking cavity so as to heat food through heat radiation; the light wave tube comprises a first light wave tube extending in an arc shape and two second light wave tubes arranged at the two ends of the first light wave tube respectively; wherein the first containing cavity in the first light wave tube communicates with the second containing cavity in the second light wave tube to form a containing cavity used for containing the heating wire, and the heating wire located in the first containing cavity and the heating wire located in the second containing cavity are both arranged in a winding mode. According to the cooking device, the uniformity degree of food heating can be effectively improved.

Owner:GUANGDONG MIDEA CONSUMER ELECTRICS MFG CO LTD

A flexible far-infrared heating aramid fiber nanofiber film and its preparation method

ActiveCN109763374BEvenly heatedNo hair lossCellulosic pulp after-treatmentNon-fibrous pulp additionPolymer scienceCarbon nanotube

Owner:SHAANXI UNIV OF SCI & TECH

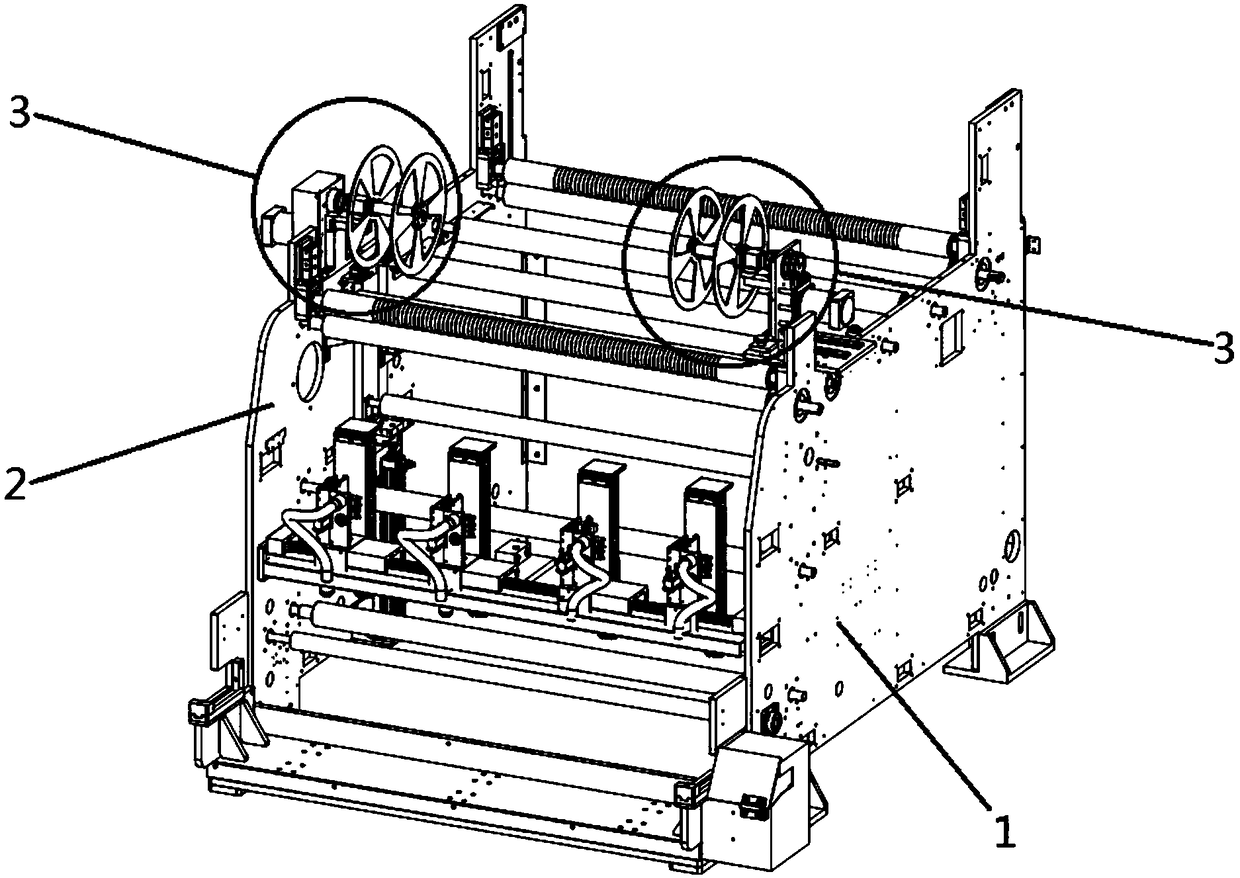

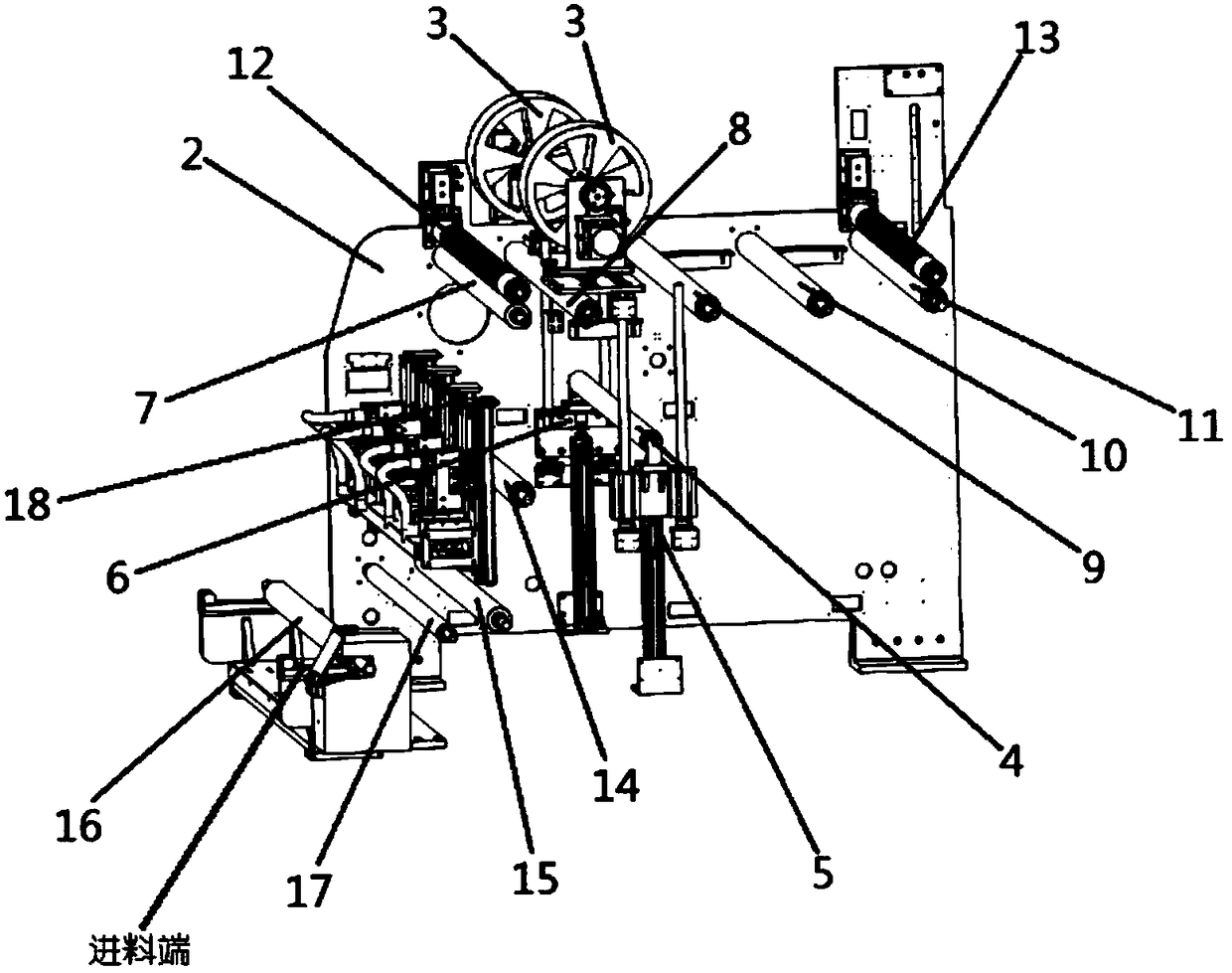

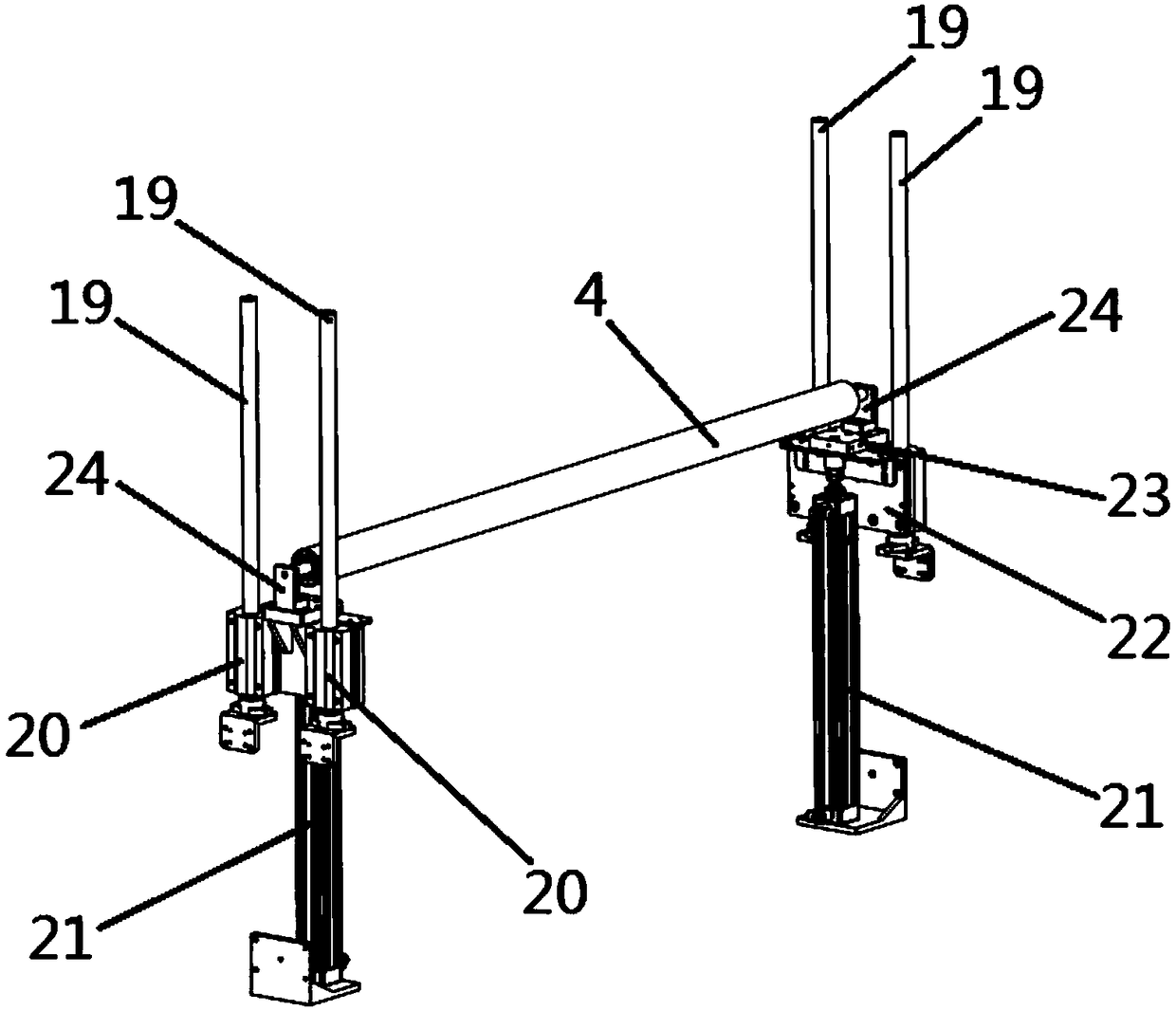

Buffer material mechanism

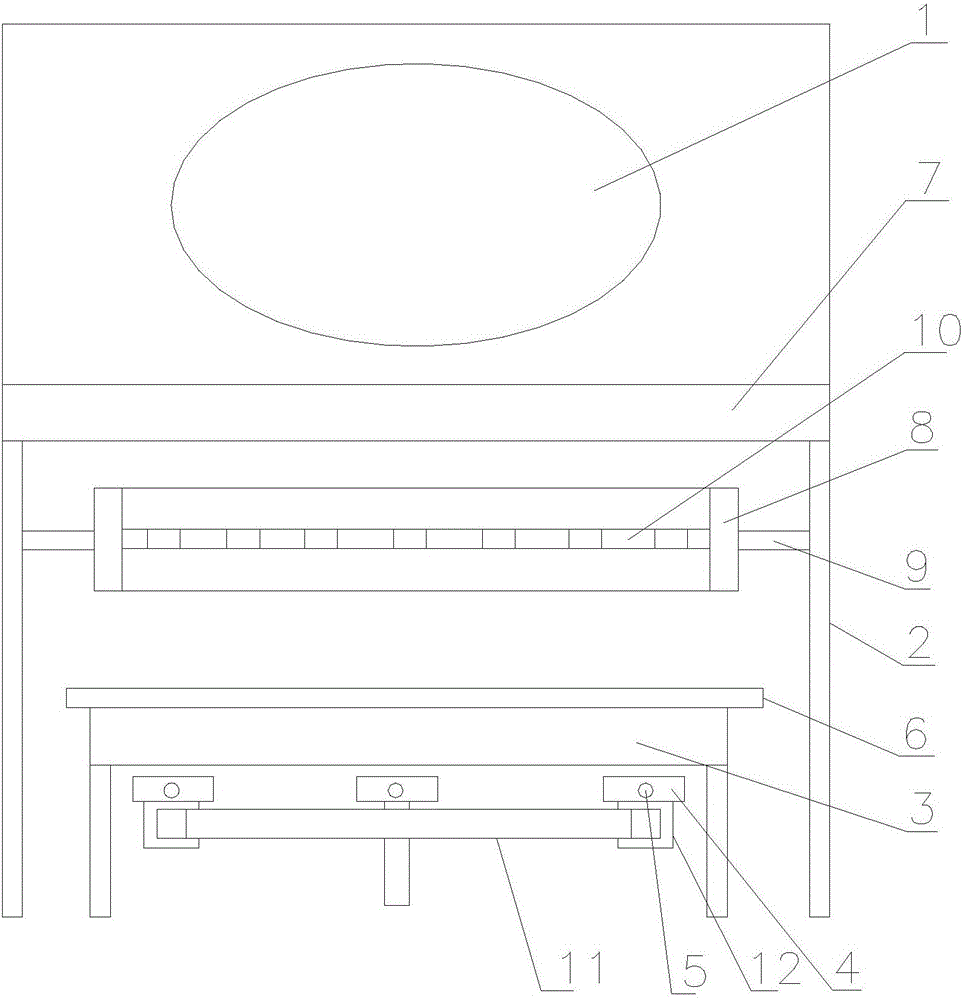

PendingCN108545527ARealize the function of buffer storageRealize the function of continuous dynamic heatingWebs handlingComputer science

The embodiment of the invention discloses a buffer material mechanism. The buffer material mechanism is used for solving the technical problems that a buffer process does not exist in the material conveying process of existing cutting machines, consequently, part of materials are heated unevenly, and white points of straight-cut splits exist. The buffer material mechanism disclosed by the embodiment comprises a first machine frame, a second machine frame and a buffer material device. The buffer material device comprises a charging air swelling shaft, a transition shaft, a first pulling shaft,a third pulling shaft, a fifth pulling shaft, a second pressing roller and a floating roller. The first pulling shaft, the third pulling shaft and the fifth pulling shaft are transversely arranged between a first machine frame and a second machine frame and connected with the first machine frame and the second machine frame. A first end of the floating roller is connected with a first driving assembly. A second end of the floating roller is connected with a second driving assembly. The floating roller is transversely arranged between the first machine frame and the second machine frame and canbe driven to move between the first pulling shaft and the third pulling shaft in the vertical direction.

Owner:GUANGDONG ZHENGYE TECH

A kind of preparation method of graphene-polymer composite material

The invention discloses a preparation method of a graphene and macromolecule composite material. The preparation method comprises the following steps: firstly dispersing a graphene derivative in a solvent, mixing a solid particulate matter to form a mixture, drying the mixture, performing heating treatment on the mixture through a microwave heating zone at a set speed in a set atmosphere to convert the graphene derivative in the mixture into grapheme, subsequently cooling to obtain a mixture of the grapheme and the solid particulate matter, and then compounding the mixture and macromolecules through methods of melting, bonding, forming and the like to obtain a grapheme-macromolecule compound. The preparation method disclosed by the invention solves the problems of difficult graphene dispersion and poor graphene derivative performance, can be used for conveniently and quickly producing the graphene and macromolecule composite material in batch and is expected to make a contribution to further development and application of the graphene and macromolecule material.

Owner:SOUTHEAST UNIV

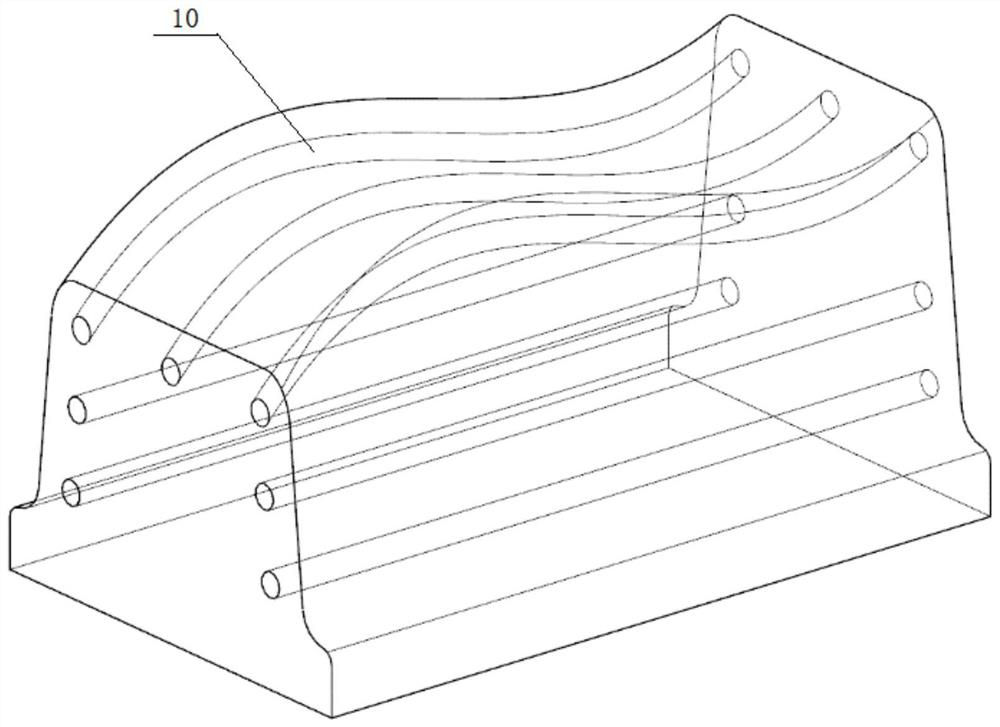

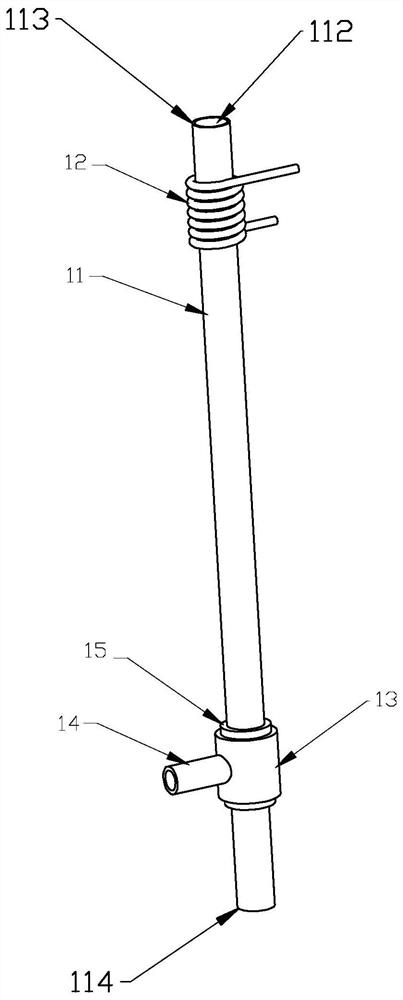

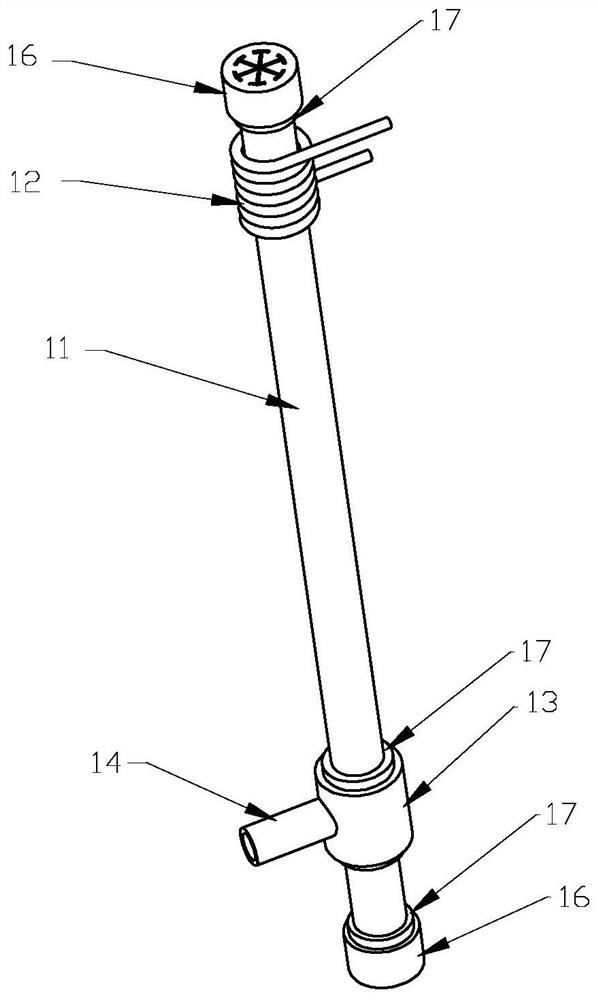

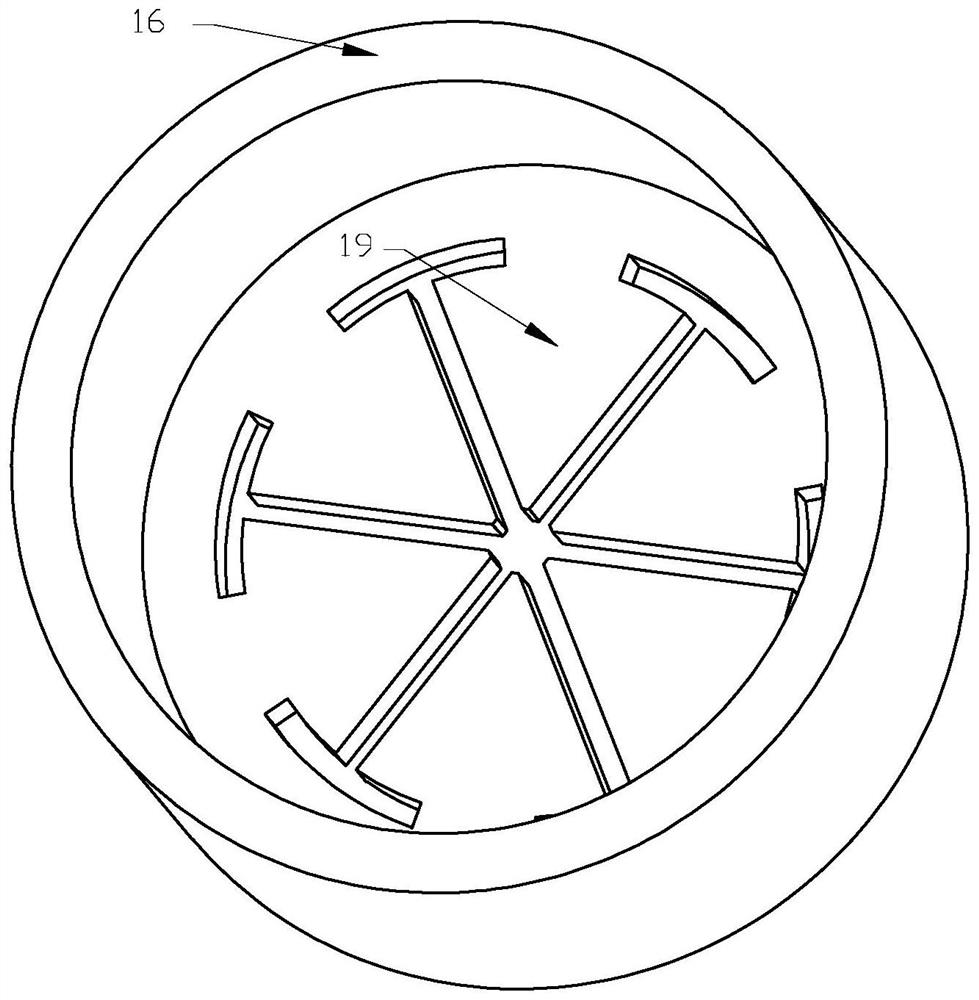

Heat treatment device for elastic titanium-nickel alloy glasses leg linear blank

PendingCN112410700AImprove uneven heatingSimple structureIncreasing energy efficiencyFurnace typesGlass tubeHeat treating

The invention discloses a heat treatment device for an elastic titanium-nickel alloy glasses leg linear blank. The heat treatment device comprises a heat-resistant glass tube, a high-frequency coil and a protective gas introducing device, the heat-resistant glass tube is vertically arranged and provided with a through hole in the axial direction, the through hole comprises a feeding port and a discharging port, the high-frequency coil is wound around the outer circumferential face of the heat-resistant glass tube, and the protective gas introducing device is communicated with the through hole.The high-frequency coil is wound on the heat-resistant glass tube and is used for heating the heat-resistant glass tube, so that the environment temperature in the through hole serving as a linear blank passing path meets the heat treatment requirement. The protective gas introducing device is arranged, and protective gas is introduced into the through hole of the heat-resistant glass tube from agas hole in the heat-resistant glass tube, so that the linear blank is protected by the protective gas when passing through the through hole.

Owner:WENZHOU SHENGLAN IND & TRADE

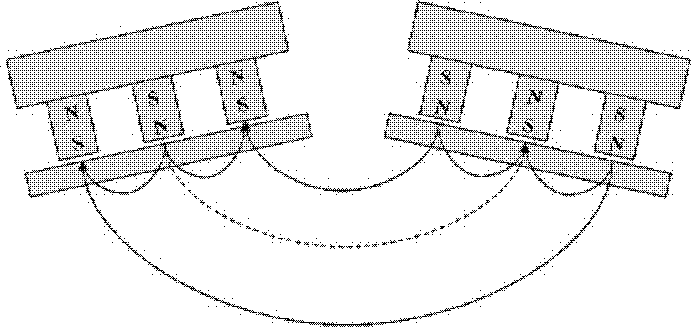

Method for preparing nanometer silicon film through intermediate-frequency magnetron sputtering process, and its special device

InactiveCN102817004BImprove uneven distributionAssisted depositionMaterial nanotechnologyVacuum evaporation coatingHigh rateIntermediate frequency

The invention relates to the silicon film material preparation filed, and concretely relates to a method for preparing a nanometer silicon film through an intermediate-frequency magnetron sputtering process, and its special device. The method comprises the following steps: sputtering non-equilibrium state twin magnetron silicon targets forming a coupling magnetic field with an applied solenoid by adopting an intermediate-frequency power supply to excite a plasma through utilizing the intermediate-frequency magnetron sputtering process; depositing a nanometer silicon film on a substrate, wherein sputtering of an Ar gas is adopted, the pressure is measured by an ionization gauge, the pressure is controlled between 0.2 and 1.5 in the whole deposition process, the current of the applied solenoid is 0-6A, and the deposition time is 30-90min; evacuating a vacuum chamber to 10<-3>-10<-4>Pa through adopting a vacuum pump group; and heating the substrate to 400-500DEG C to obtain the nanometer silicon film. In the invention, the applied solenoid is adopted to continuously adjust the nonequilibrium degrees of the twin targets, so high-rate ion auxiliary deposition of the nanometer silicon film under low power is realized, the crystal structure of the film is controllable in a large range, and the optical band gap is adjustable.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

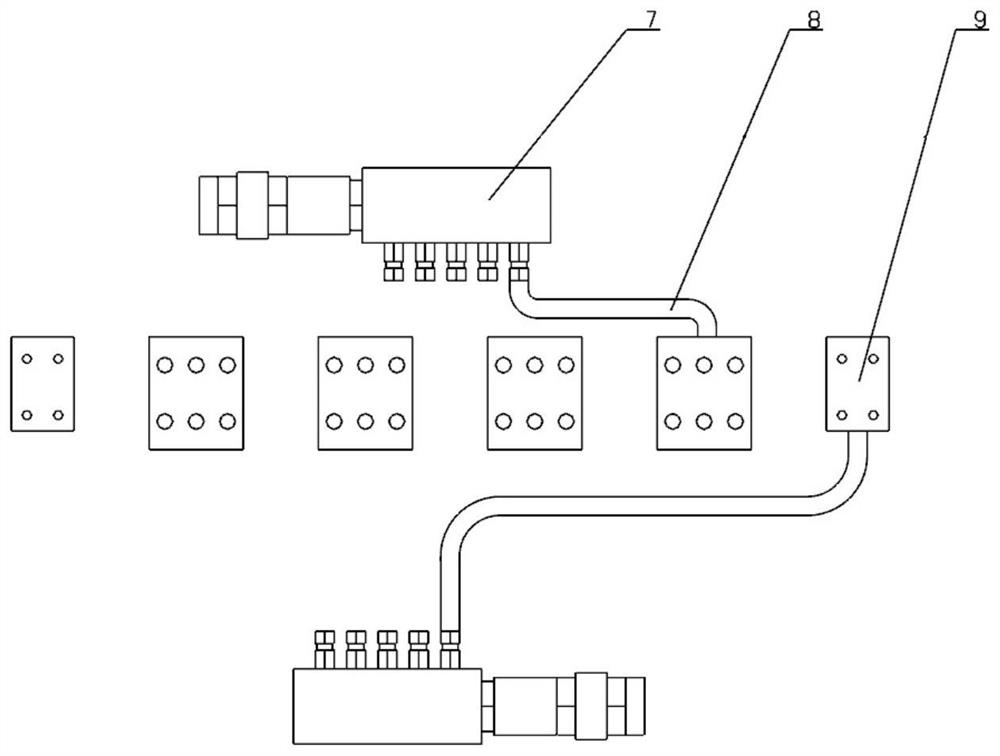

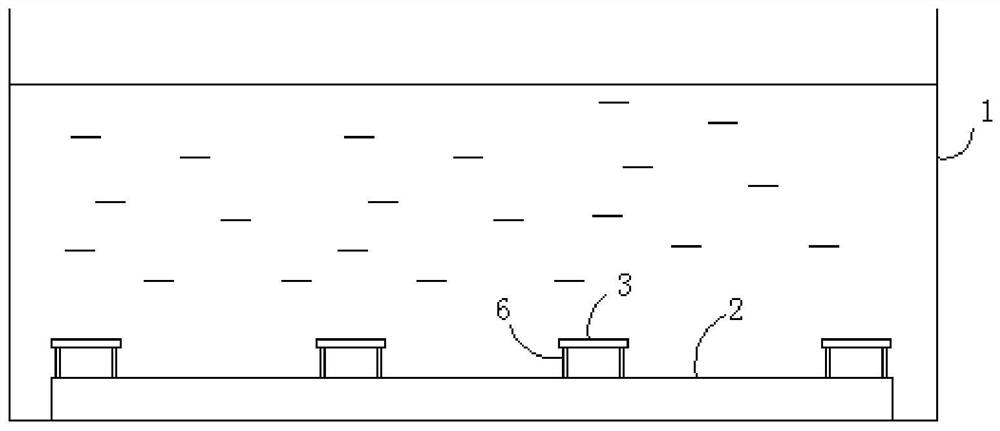

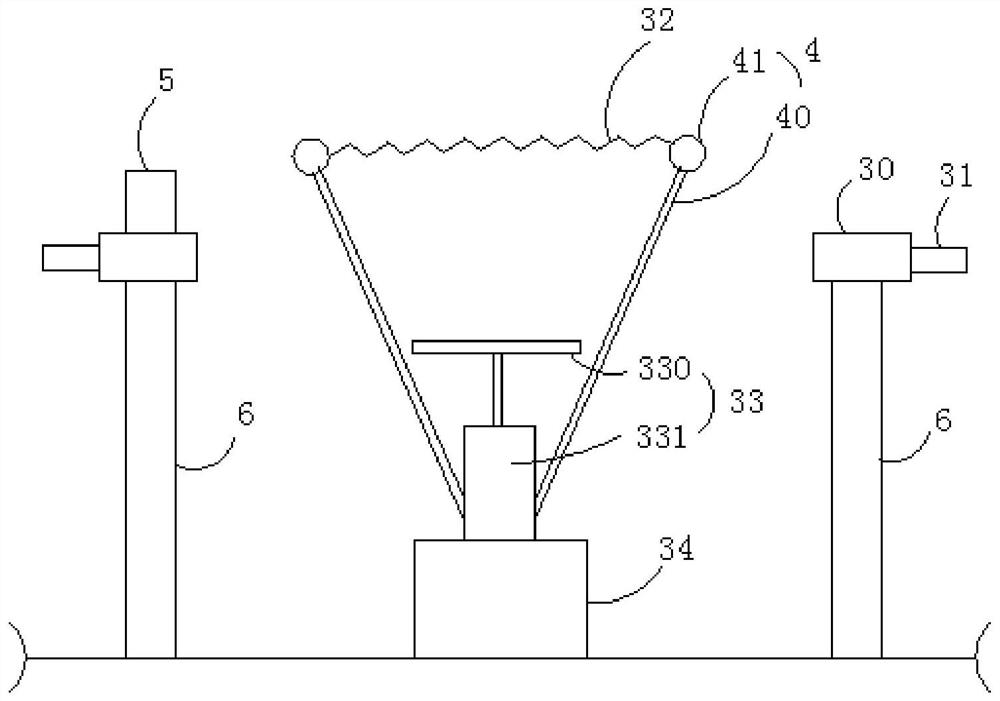

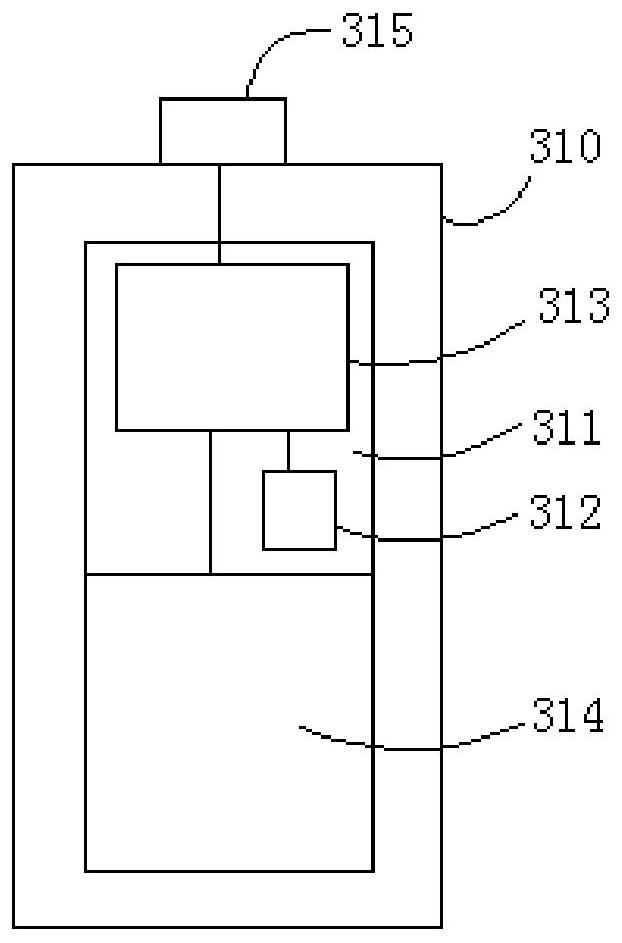

Tap water treatment biological tank temperature regulation and control device and method

InactiveCN113716678AImprove uneven heatingGood temperature compensation in different areasWater treatment parameter controlBiological water/sewage treatmentBiologyWater treatment

The invention relates to a tap water treatment biological tank temperature regulation and control device. The device comprises a biological tank, a mounting rack is arranged at the bottom of the biological tank, and a plurality of temperature detection regulation and control units are uniformly distributed on the mounting rack. Each temperature detection regulation and control unit comprises a connecting ring, and three temperature sensing units are uniformly distributed on each connecting ring. Each temperature detection regulation and control unit further comprises a heating assembly, a rotating assembly and a deflection adjusting assembly. The connecting rings are further provided with a controller, and the controller receives data sensed by the temperature sensing units and regulates and controls the heating assembly, the rotating motor and the deflection adjusting assembly. The problem of uneven temperature rise in the prior art is solved, meanwhile, temperature compensation of different areas can be well and automatically carried out, the temperature balance in the biological tank is greatly enhanced, and meanwhile the capacity of resisting external interference to the temperature can be remarkably improved.

Owner:深圳市迪卫尔环保科技有限公司

Tea frying machine with comprehensive effect

InactiveCN106359680AImprove uneven heatingEvenly heatedPre-extraction tea treatmentEngineeringThermal stability

The invention discloses a tea frying machine with a comprehensive effect. The tea frying machine comprises a pot body, wherein the pot body is arranged on a metal frame; a gas stove is arranged below the pot body; a flame gun is arranged inside the gas stove; gas is conveyed into the flame gun through gas pipelines. The tea frying machine is characterized in that the gas stove consists of an inner layer and an outer layer; and three gas pipelines are respectively positioned on the outer layer, the inner layer and another outer layer of the gas stove. The tea frying machine has the beneficial effects that the situation of non-uniform heating can be alleviated by using multiple heat sources, tea leaves can be uniformly heated, a good tea frying effect can be achieved, meanwhile, the heat source on the outer layer can be moved, so that the fixed heat source can be changed into a movable heat source, the whole heating stability can be enhanced, and the tea frying machine is simple and practical and remarkable in effect.

Owner:梁本家

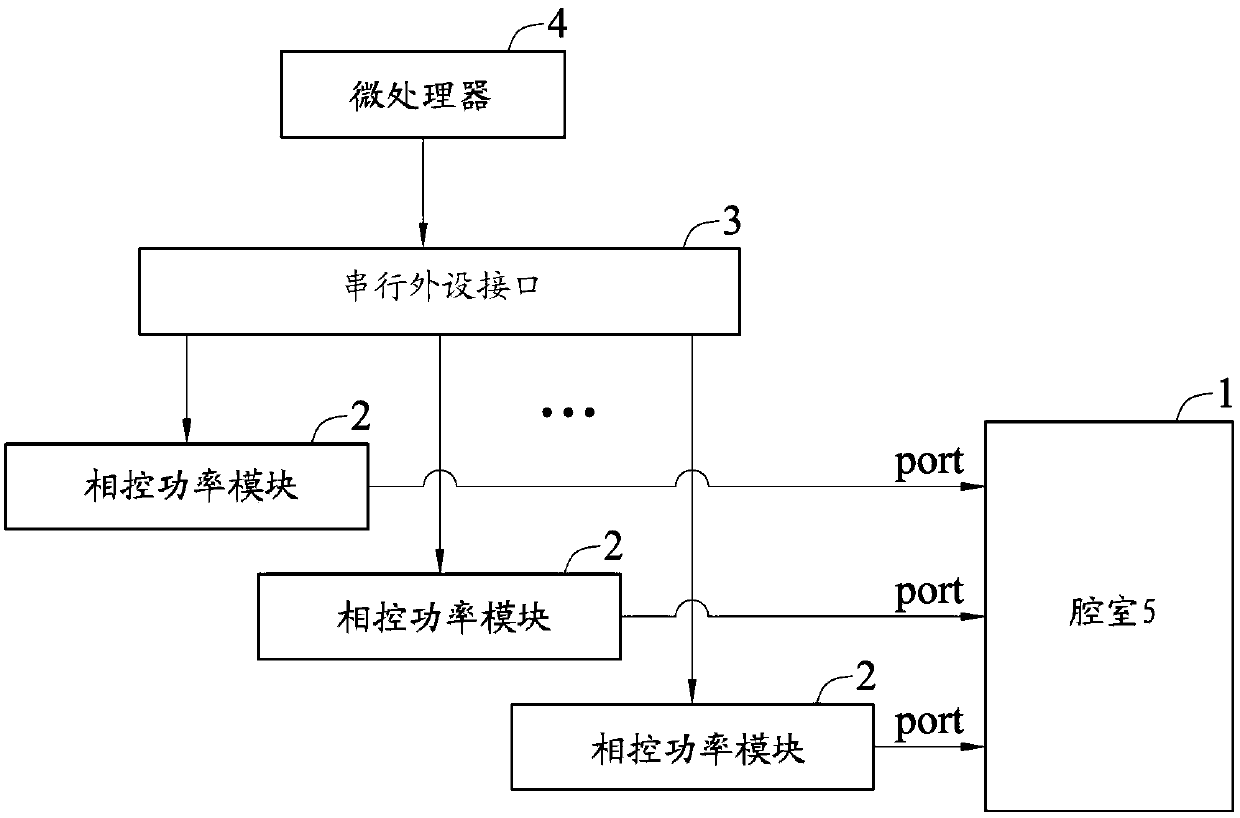

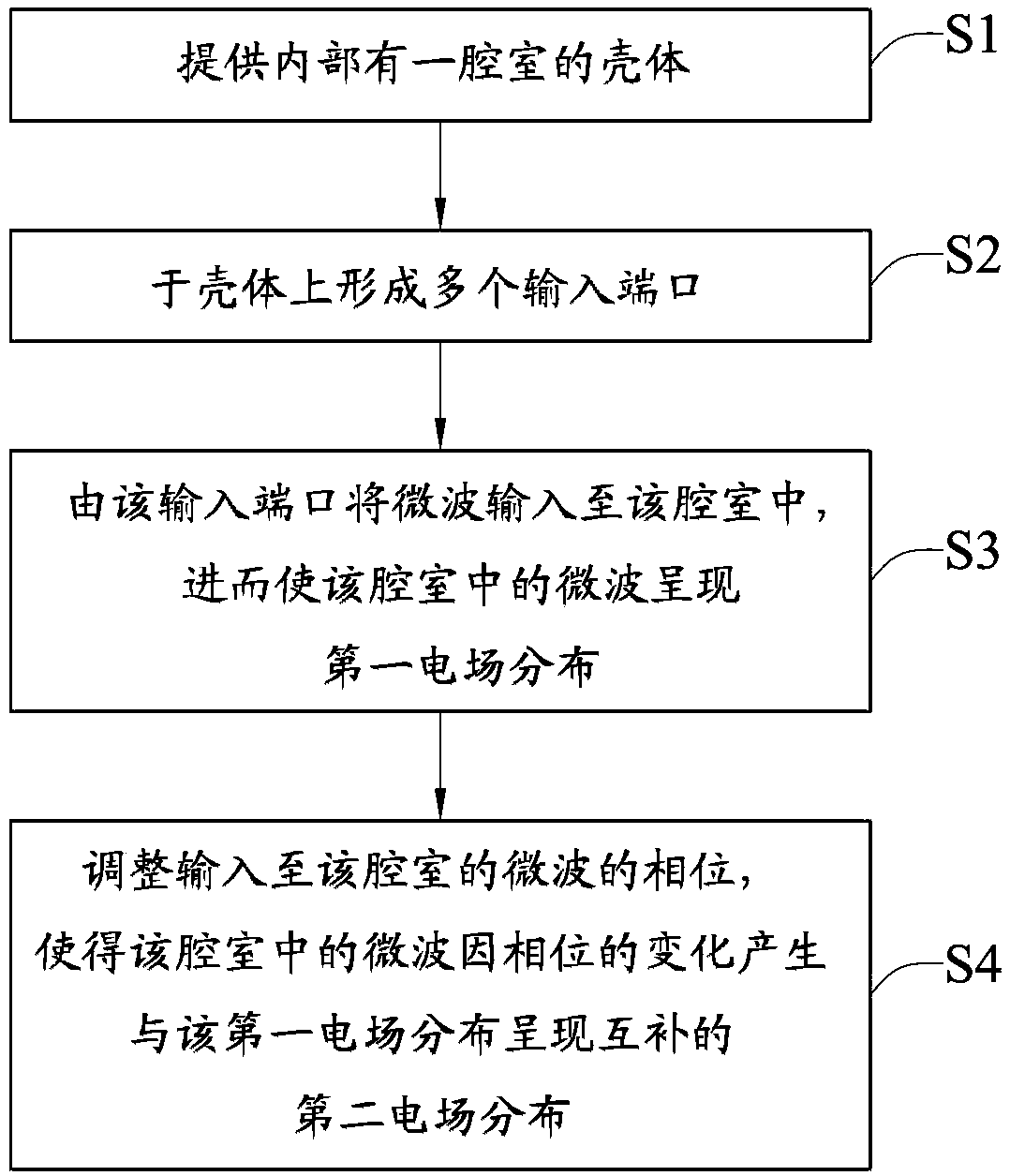

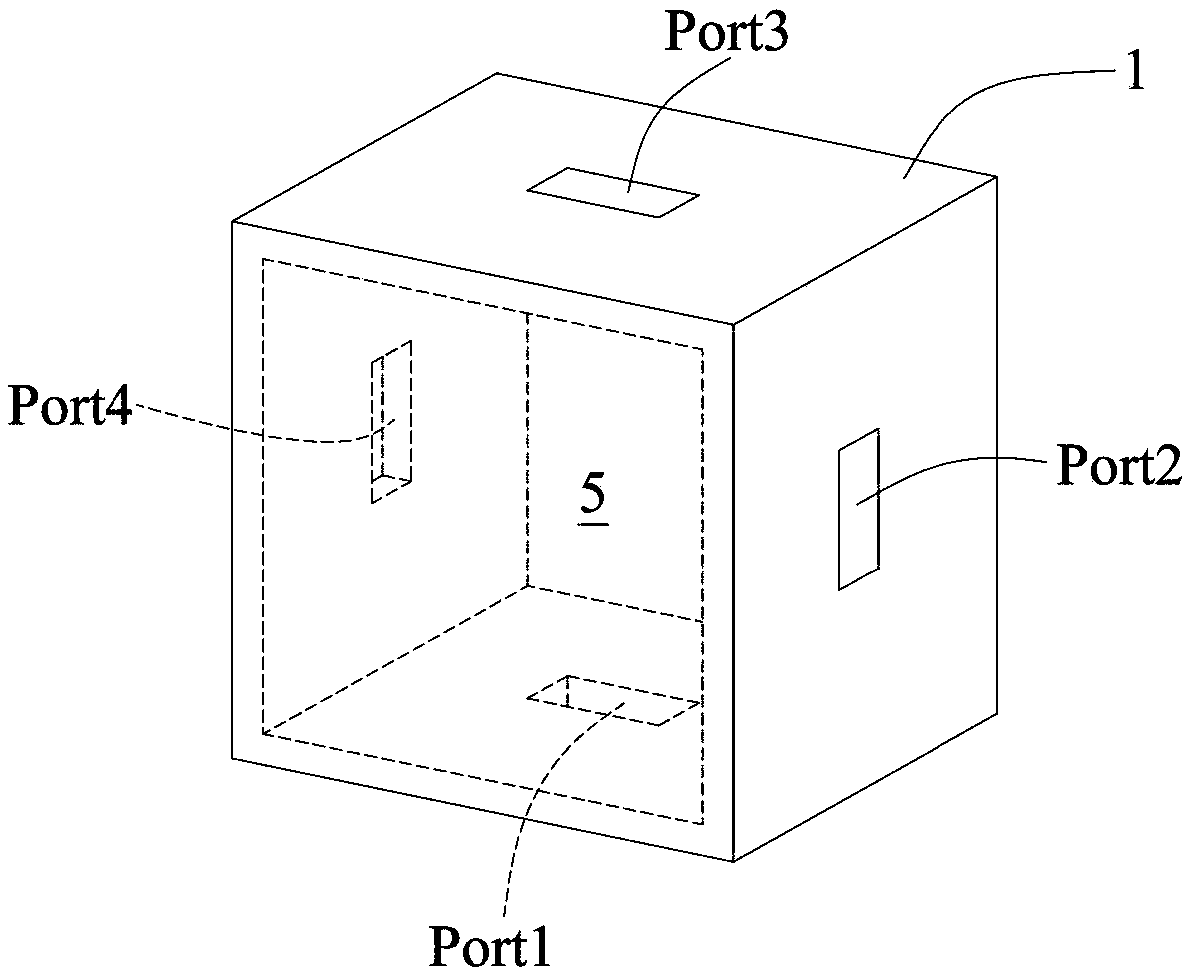

Distributed microwave phase control method

The invention discloses a distributed microwave phase control method, which comprises the following steps that a plurality of phase control power modules input microwaves into a cavity through each input port, so that the microwaves in the cavity are distributed in a first electric field; and each phase control power module adjusts the phase of the microwaves input into the cavity by each input port, so that the microwaves in the cavity generate second electric field distribution complementary to the first electric field distribution due to the change of the phase.

Owner:IND TECH RES INST

A method for laser high temperature brazing assisted by self-propagating reaction of nano-multilayer film

InactiveCN106695141BImprove connection strengthIncrease the areaSoldering apparatusWelding apparatusLap jointOptoelectronics

The invention belongs to the technical field of laser welding, and provides a method for assisting high-temperature laser brazing through self-propagating reaction of a nano-multilayer film. A double-metal nano-film is alternately deposited on a substrate by adopting a magnetron sputtering method; the deposited double-metal nano-multilayer film is stripped from the substrate; the stripped multilayer film is arranged between two layers of brazing materials, so that a composite intermediate layer is formed; surface pretreatment is conducted on base materials to be welded; and the composite intermediate layer is arranged between obtained base materials, a lap joint mode is adopted for welding, and lasers are adopted for carrying out scanning welding on the composite intermediate layer. The nano-multilayer film is subjected to the self-propagating reaction after being ignited by the lasers, a large amount of heat released by the reaction can melt low-melting-point brazing materials, and thus connection is achieved on both lap joints and whole lap-joint faces in the welding process, so that the joint connecting strength is improved, and material connection is completed. By means of the method, heating nonuniformity of the lasers used as local heat sources can be relieved, the more uniform interface reaction is achieved, and the joint density can be increased.

Owner:BEIJING UNIV OF TECH

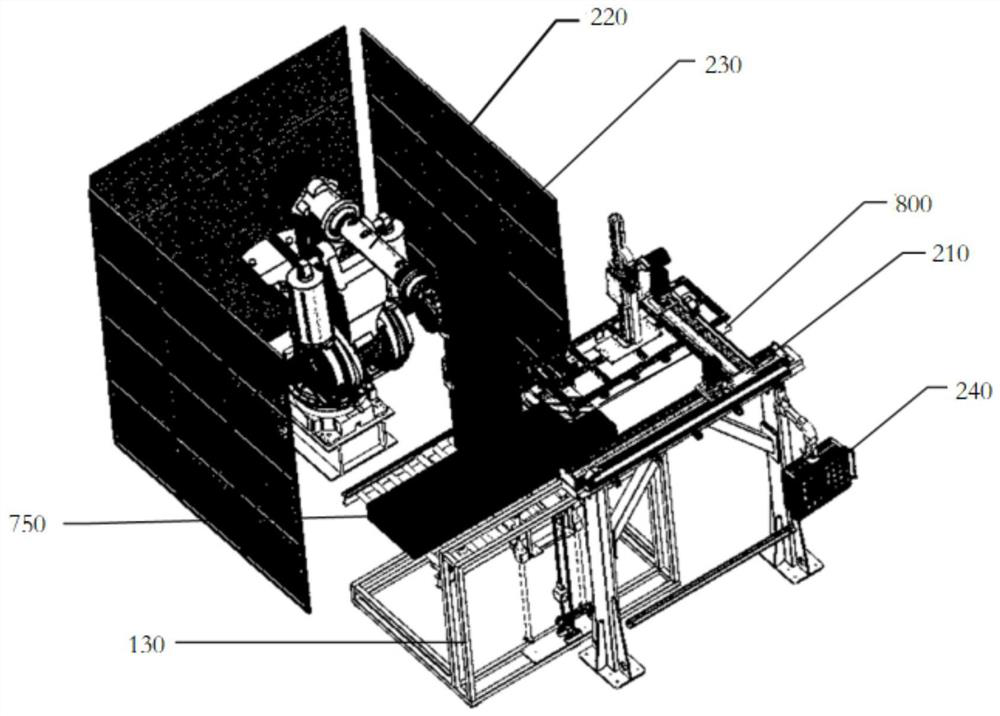

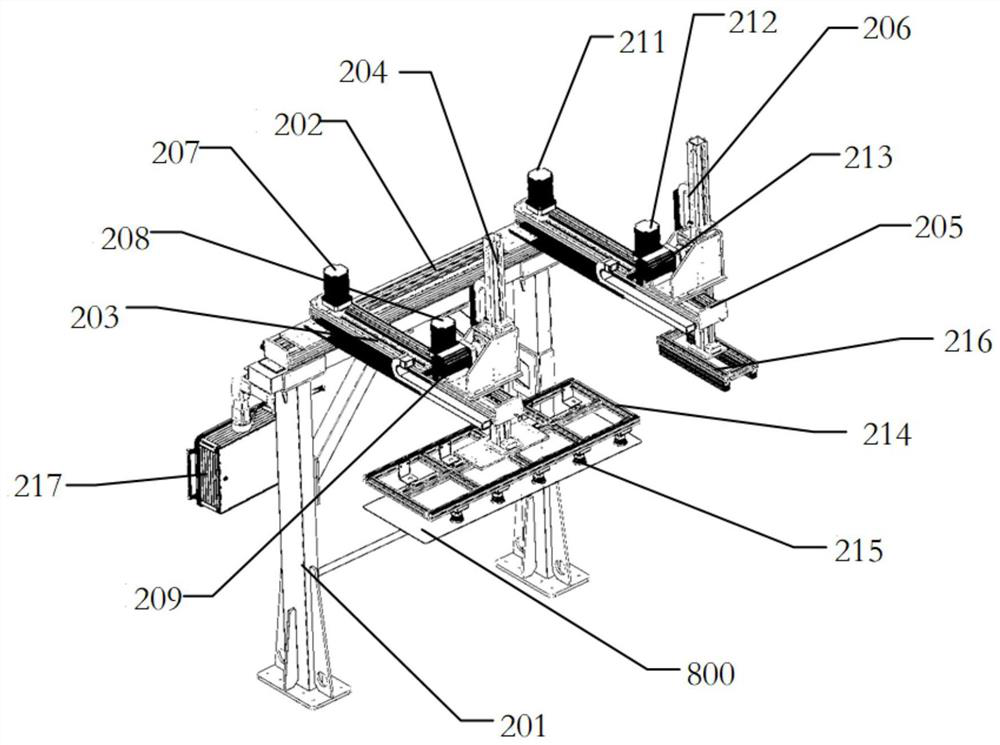

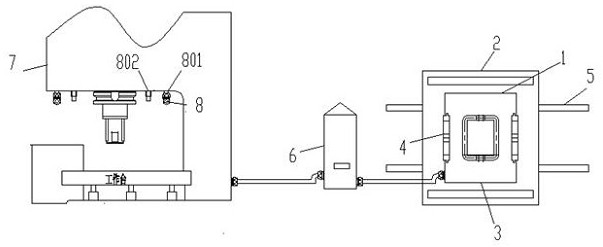

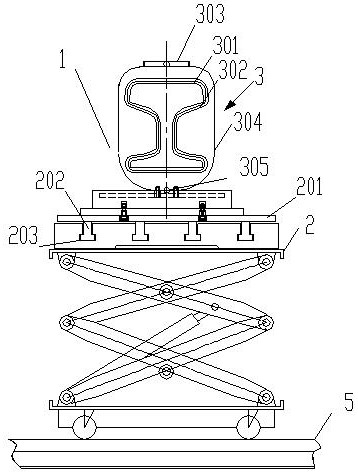

Asymmetric section steel rail straightening and preheating device

PendingCN113245411AWarm up evenlyImprove heating efficiencyMetal-working feeding devicesPositioning devicesEngineeringMechanical engineering

The invention provides an asymmetric section steel rail straightening and preheating device which comprises a steel rail preheating device. The steel rail preheating device is mounted at the top of a lifting platform. The lifting platform does translation along X-direction trolley rails. The steel rail preheating device comprises a steel rail preheating tool. The steel rail preheating tool is of an I-shaped structure in bilateral symmetry. Steel rail outline lateral auxiliary positioning devices are detachably mounted on the left side and the right side of the steel rail preheating tool. By means of the asymmetric section steel rail straightening and preheating device, the problem about rapid local preheating of an asymmetric section steel rail is solved, the preheating process progress is accelerated, the preheating operation difficulty is reduced, use is convenient, the number of times of clamping is reduced, the machining efficiency is improved, and the machining quality is guaranteed.

Owner:CHINA RAILWAY BAOJI BRIDGE GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com