Network-shaped electrode applicable to high-power GaN-based LED chips

A LED chip and network-like technology, applied in circuits, electrical components, semiconductor devices, etc., can solve problems such as unsatisfactory current expansion, and achieve the effects of improving uneven heating, uniform current flow, and improving current distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

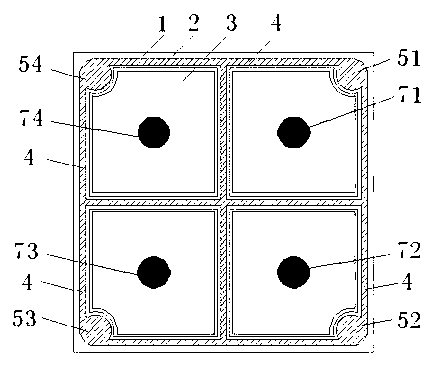

Embodiment 1

[0032] See attached figure 1 . A network electrode suitable for high-power GaN-based LED chips, using a chip with a size of 1mm×1mm. First, grooves 2 are etched on the front of the GaN epitaxial layer until the N layer, and the chip is divided into 4 mesas 1 : The line width of the mesa 1 is 100 microns, and the line width of the trench 2 is 30 microns; the mesa 1 is a rectangular structure, and its length and width are 762 microns. The trench 2 completely disconnects the quantum well layer, the superlattice layer, and the P-type GaN layer on the N-type layer of the four mesas 1 . Metal electrodes are deposited in the trench 2 and on the mesa 1, and the metal line width in the trench 2 and on the mesa 1 is 20 microns.

[0033] The N-type electrode is a network formed by the first N-type metal pad 51, the second N-type metal pad 52, the third N-type metal pad 53, the fourth N-type metal pad 54 and the N-type metal electrode 4. The N-type metal electrode 4 is a strip electrod...

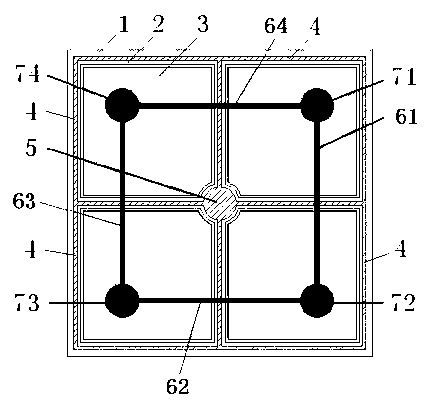

Embodiment 2

[0038] See attached figure 2 . A network electrode suitable for high-power GaN-based LED chips, using a chip with a size of 762 microns × 762 microns. First, grooves 2 are etched on the front of the GaN epitaxial layer until the N layer, and the chip is divided into 4 mesas. 1: The line width of trench 2 is 23 microns, and the line width of mesa 1 is 76 microns. The groove 2 completely disconnects the quantum well layer, the superlattice layer, and the P-type GaN layer on the N-type layer of the four mesas 1 . Metal electrodes are deposited in the trench 2 and on the mesa 1, and the metal line width in the trench 2 and on the mesa 1 is 15 microns.

[0039] The N-type electrode is a network electrode composed of N-type metal pads 5 and N-type metal electrodes 4. The N-type metal electrodes 4 are strip-shaped electrodes interlaced to form a network, and are arranged on the mesa structure of the mesa 1. Buried by a silicon dioxide passivation layer and isolated from the edge ...

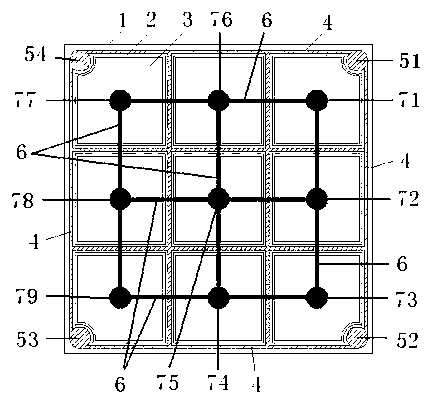

Embodiment 3

[0044] See attached image 3 . A network electrode suitable for high-power GaN-based LED chips, using a chip with a size of 1500 microns × 1500 microns. First, grooves 2 are etched on the front of the GaN epitaxial layer until the N layer, and the chip is divided into 9 mesas. 1: The line width of trench 2 is 45 microns, and the line width of mesa 1 is 150 microns. The groove 2 completely disconnects the quantum well layer, the superlattice layer, and the P-type GaN layer on the N-type layer of the nine mesas 1 . Metal electrodes are deposited in the trench 2 and on the mesa 1, and the metal line width in the trench 2 and on the mesa 1 is 30 microns.

[0045] The N-type electrode is a network formed by the first N-type metal pad 51, the second N-type metal pad 52, the third N-type metal pad 53, the fourth N-type metal pad 54 and the N-type metal electrode 4. The N-type metal electrode 4 is a strip-shaped electrode interlaced to form a network, which is arranged on the mesa ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com