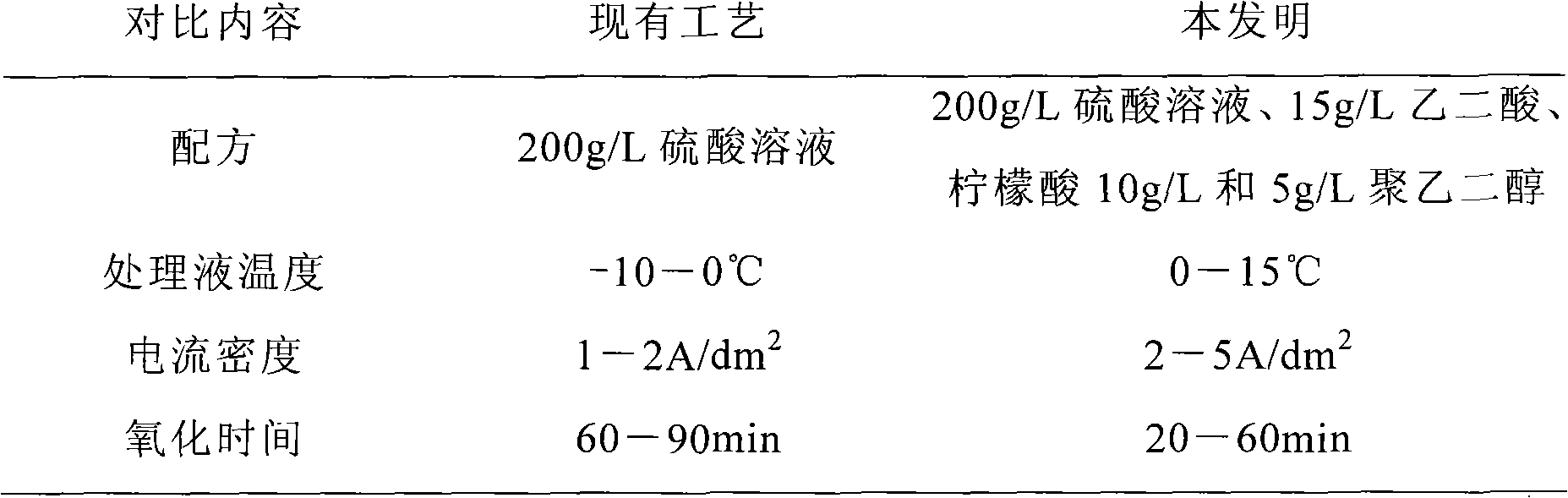

Additive, solution and technology used for hard anodic oxidation of high-silicon aluminum alloy

A hard anodic oxidation, high-silicon aluminum alloy technology, applied in the direction of electrolytic coating, surface reaction electrolytic coating, coating, etc., to achieve the effect of reducing cell voltage, improving appearance quality, and avoiding ablation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

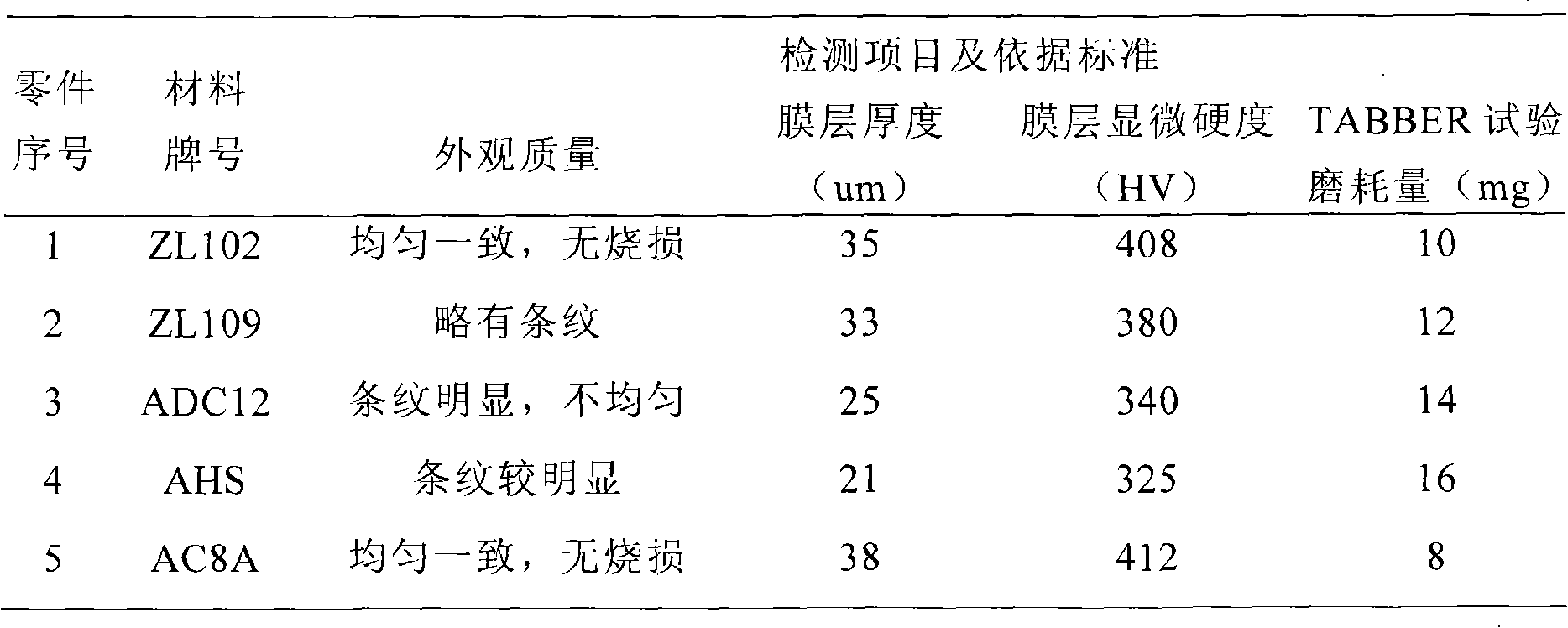

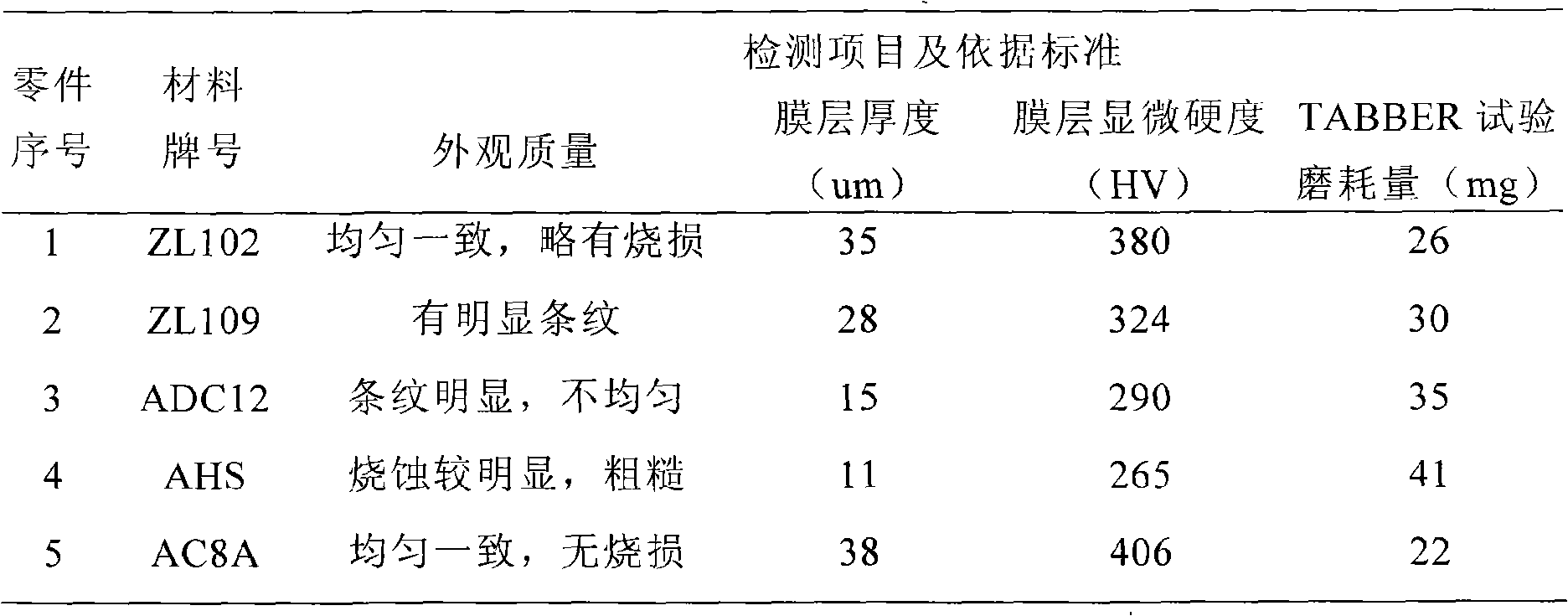

Examples

Embodiment 1

[0063] Embodiment 1 is to the hard anodic oxidation of automobile air-conditioning compressor parts-planet disc

[0064] The product is an A3 56 aluminum alloy with a Si content of 6.5-7.5% and an area of 1.8dm 2 .

[0065] This product is installed in the car air-conditioning compressor and works under the conditions of high temperature, high pressure and frequent dynamic friction. The specific technical requirements for processing are: the oxide film is uniform, the thickness is 20-25μm, the microhardness of the film layer is 400-500Hv, and the wear amount of the TABER test is less than 20mg.

[0066] Each liter of hard anodizing solution contains: 180g of sulfuric acid, 20g of oxalic acid, 15g of citric acid and 5g of polyethylene glycol (PEG200).

[0067] The process flow is: degreasing at 55°C for 10 minutes—water washing—pickling for 60 seconds—water washing—hard anodizing current density 3A / dm 2 , 10°C, 40min——water washing——90°C sealing for 10min——100°C drying for...

Embodiment 2

[0071] Embodiment 2 is to the hard anodic oxidation of automobile air-conditioning compressor parts-piston

[0072] The product is ZL102 aluminum alloy with Si content of 10-13%, with an area of 0.16dm 2 .

[0073] This product is installed in the compressor of automobile air conditioner and works under the conditions of high temperature, high pressure and frequent dynamic friction. The specific technical requirements for processing are: the oxide film is uniform, the thickness is 30-40um, the microhardness of the film layer is >350Hv, and the wear amount of the TABER test is <20mg.

[0074] Each liter of hard anodizing solution contains: 200g of sulfuric acid, 25g of oxalic acid, 15g of citric acid and 8g of polyethylene glycol (PEG200).

[0075] The process flow is: degreasing at 55°C for 10 minutes—water washing—pickling for 60 seconds—water washing—hard anodizing current density 4A / dm 2 , 10°C, 50min——water washing——90°C sealing for 10min——100°C drying for 10min.

[...

Embodiment 3

[0079] Embodiment 3 is to the hard anodic oxidation of automobile air-conditioning compressor parts - scroll

[0080] The product is an AC8A aluminum alloy with a Si content of 11-13% and an area of 3.6dm 2 .

[0081] This product is installed in the compressor of automobile air conditioner and works under the conditions of high temperature, high pressure and frequent dynamic friction. The specific technical requirements for processing are: the oxide film is uniform, the thickness is 10-20μm, the microhardness of the film layer is >350Hv, and the wear amount of the TABER test is <20mg.

[0082] Each liter of hard anodizing solution contains: 200g of sulfuric acid, 25g of oxalic acid, 20g of citric acid and 10g of polyethylene glycol (PEG400).

[0083] The process flow is: degreasing at 55°C for 10 minutes—water washing—pickling for 40 seconds—water washing—hard anodizing 3A / dm 2 , 10°C, 25min——water washing——90°C sealing for 15min——100°C drying for 20min.

[0084] The we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Microhardness | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com