Method for preparing NaY molecular sieve by in-situ crystallization

An in-situ crystallization and molecular sieve technology, applied in the direction of crystalline aluminosilicate zeolite, fajhedral crystalline aluminosilicate zeolite, etc., can solve the problems of harsh synthesis conditions, high synthesis cost, difficult industrial application, etc. Growth rate, grain size reduction, effect of slowing dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] With kaolin 2000g (calcium base), sodium silicate 4%, add deionized water and be prepared into the mixed slurry that kaolin solid content is 42%, spray drying, obtain the kaolin spray microsphere that 1840g average particle diameter is 70 μ m; The kaolin spray microsphere The balls were roasted at 950°C for 2 hours to obtain roasted high soil microspheres; the roasted high soil microspheres were soaked in 12mol / L hydrochloric acid and reacted at 45°C for 5 hours, filtered, washed with water, and dried to obtain acid-treated high soil microspheres; 50g The acid-treated high soil microspheres were mixed with 40 mL of silicon source, 95 mL of sodium hydroxide solution, and 3 mL of directing agent, crystallized at 96 ° C for 24 hours, and the filter cake was filtered, washed, and dried to obtain the in-situ crystallization product.

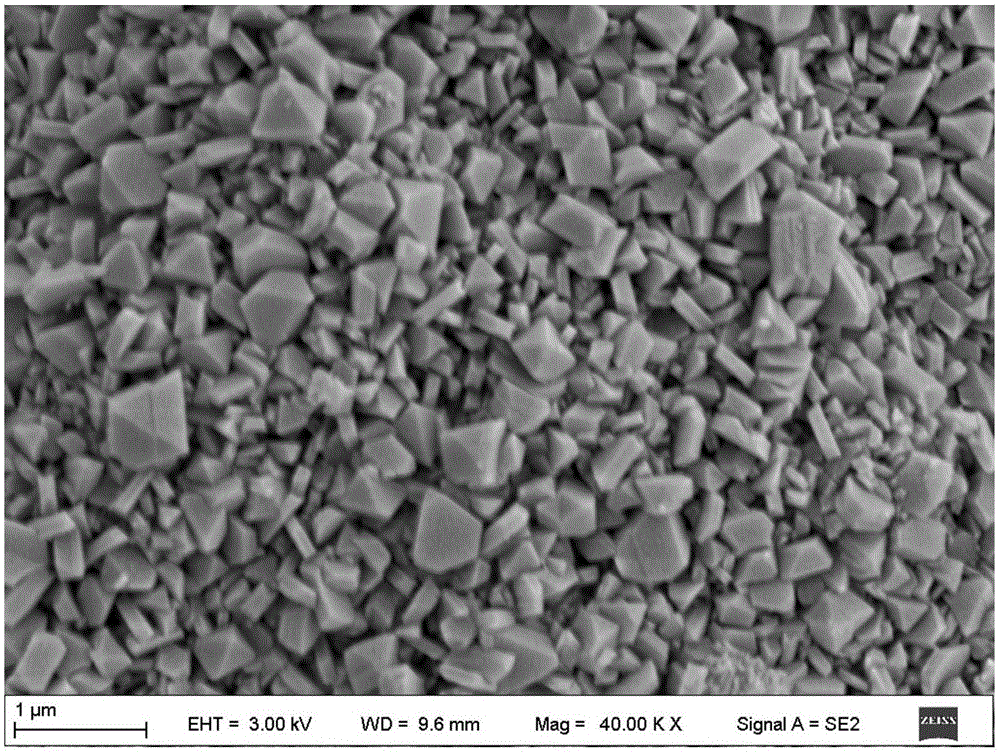

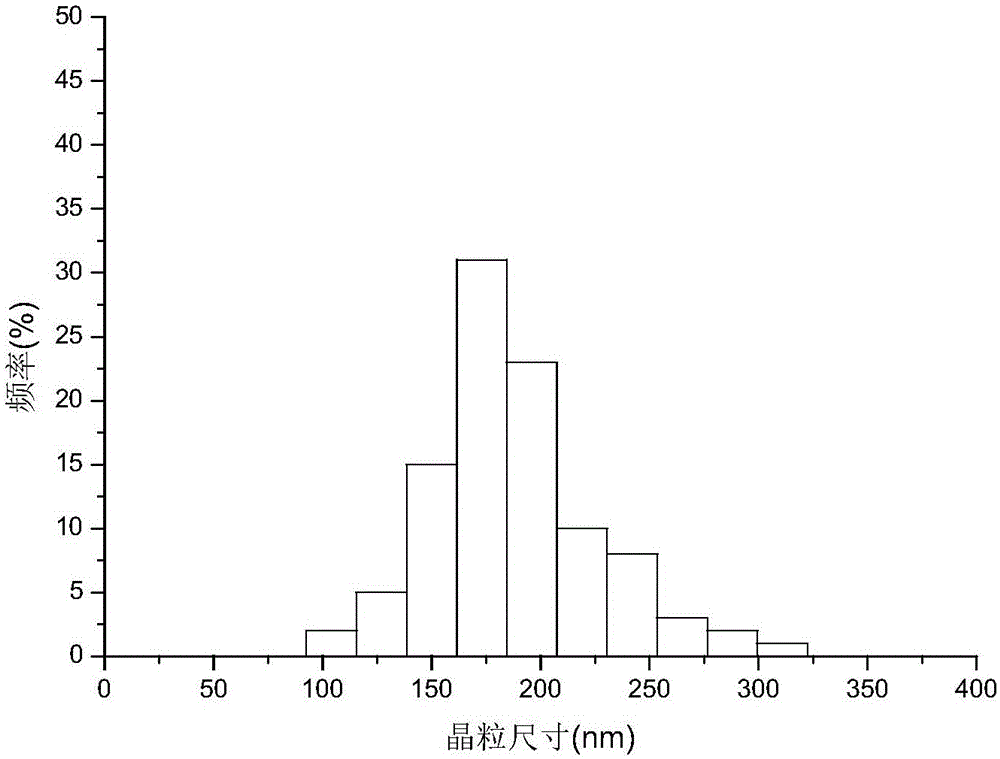

[0038] Measured by X-ray diffraction, the relative crystallinity is 24%, and its scanning electron micrograph and particle size distribution ar...

Embodiment 2

[0040] Using the roasted high soil microspheres obtained in Example 1, soak them in 6mol / L hydrochloric acid and react at 40°C for 5h, filter, wash with water, and dry to obtain acid-treated high soil microspheres; 50g of acid-modified high soil microspheres The ball was mixed with 35mL of silicon source, 90mL of sodium hydroxide solution, and 3mL of directing agent, crystallized at 94°C for 26h, and the filter cake was filtered, washed, and dried to obtain the in-situ crystallization product.

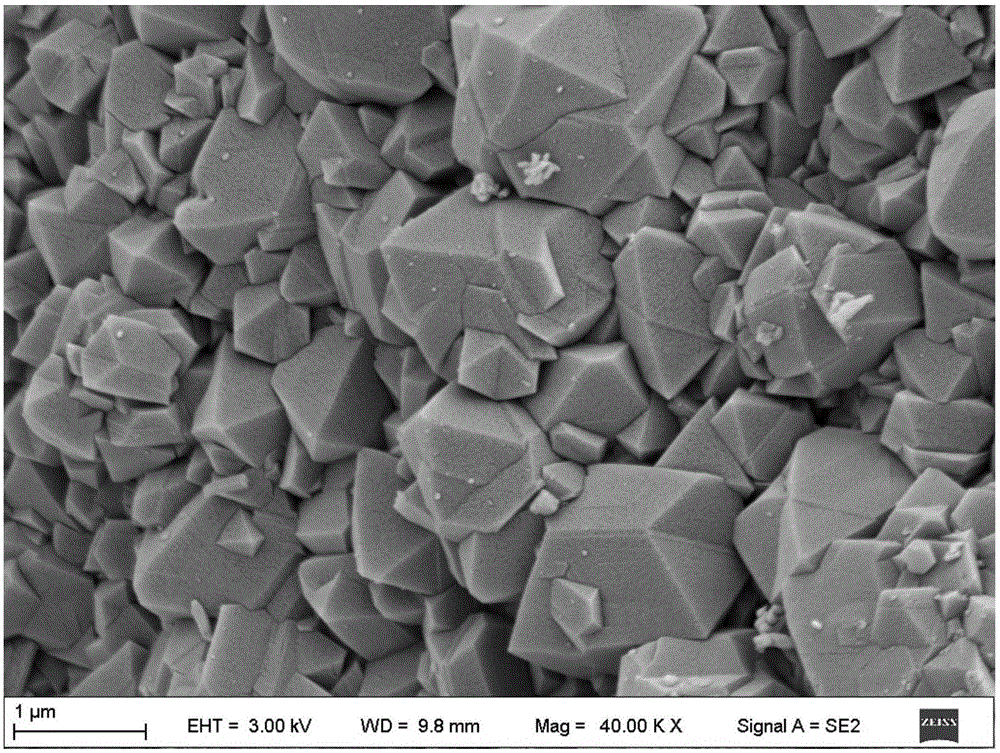

[0041] As determined by X-ray diffraction, the relative crystallinity is 27%, and the scanning electron micrograph and particle size distribution show that the obtained molecular sieve has an average particle size of 214nm.

Embodiment 3

[0043] Using the roasted high soil microspheres obtained in Example 1, soak them in 1mol / L hydrochloric acid and react at 48°C for 5h, filter, wash with water, and dry to obtain acid-treated high soil microspheres; 50g of acid-modified high soil microspheres The ball was mixed with 30mL of silicon source, 85mL of sodium hydroxide solution, and 4mL of directing agent, crystallized at 92°C for 20h, and the filter cake was filtered, washed, and dried to obtain the in-situ crystallization product.

[0044] As determined by X-ray diffraction, the relative crystallinity is 23%, and the scanning electron micrograph and particle size distribution show that the obtained molecular sieve has an average particle size of 240nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com