Apparatus and method for highly controlled electrodeposition

a technology of electroplating substrates and apparatuses, which is applied in the direction of evaporation applications, soldering apparatuses, manufacturing tools, etc., can solve the problems of inferior to a metallic ion source, insufficient control of the deposition process, and easy variation of operating geometries and other parameters of the cell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

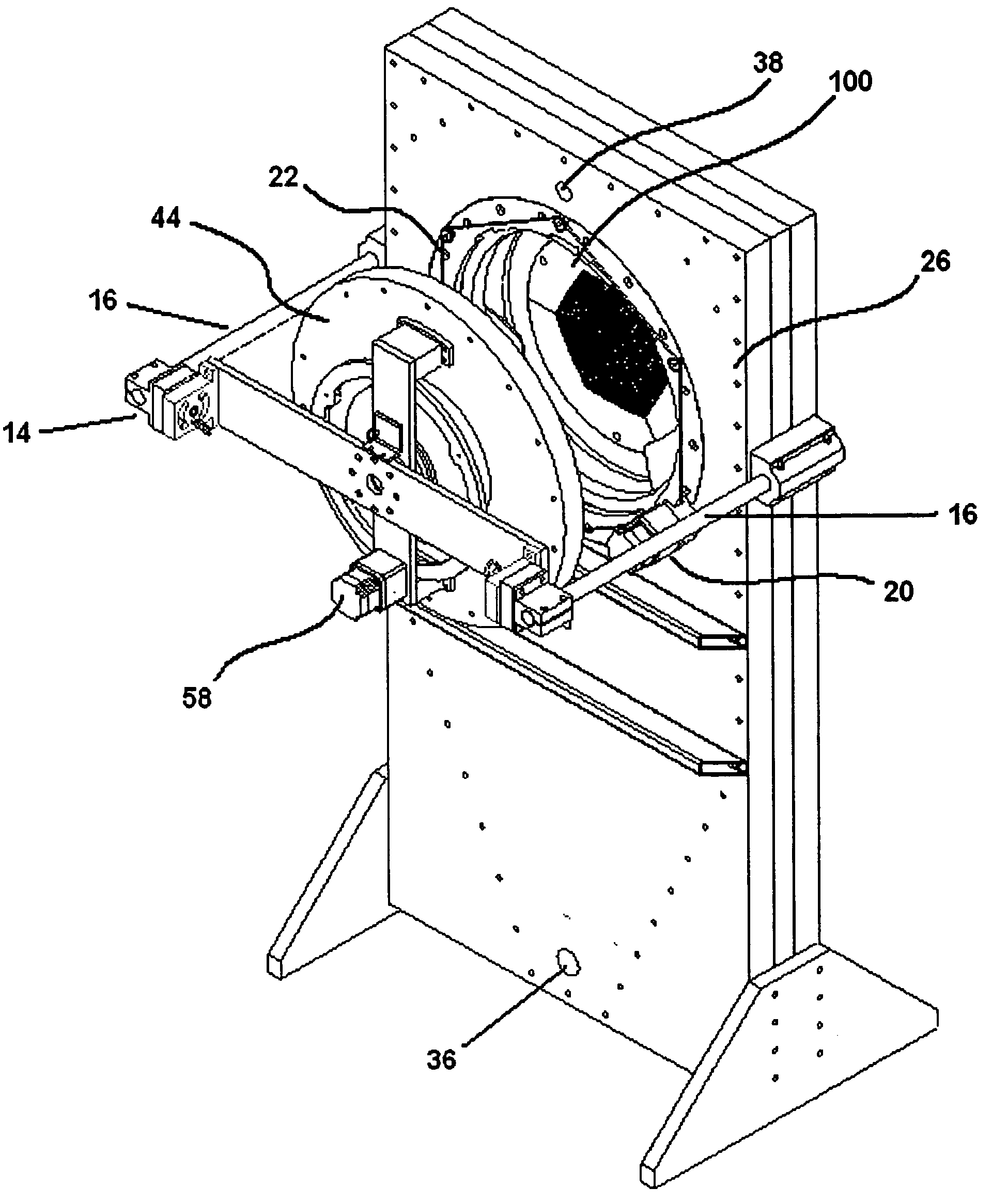

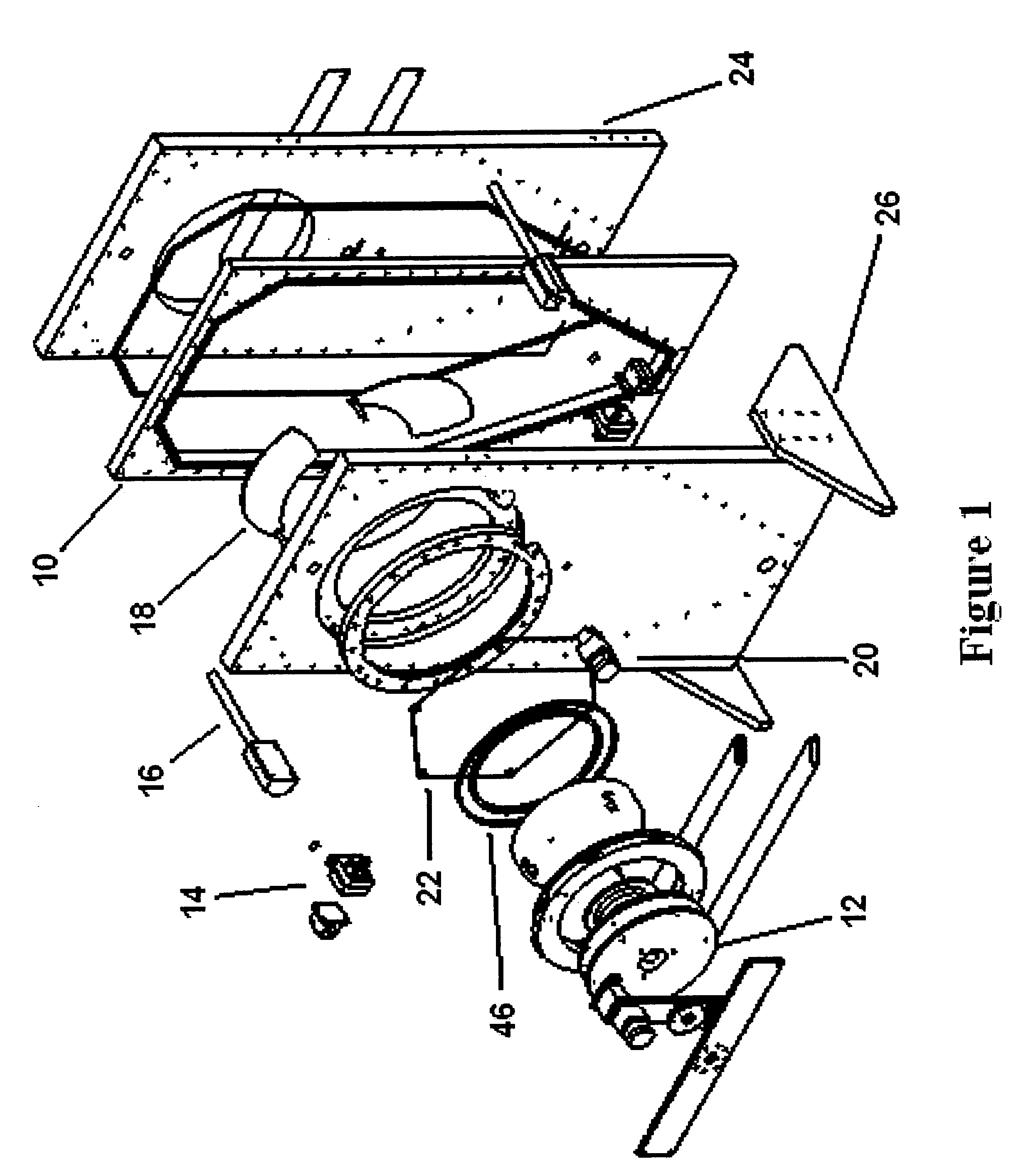

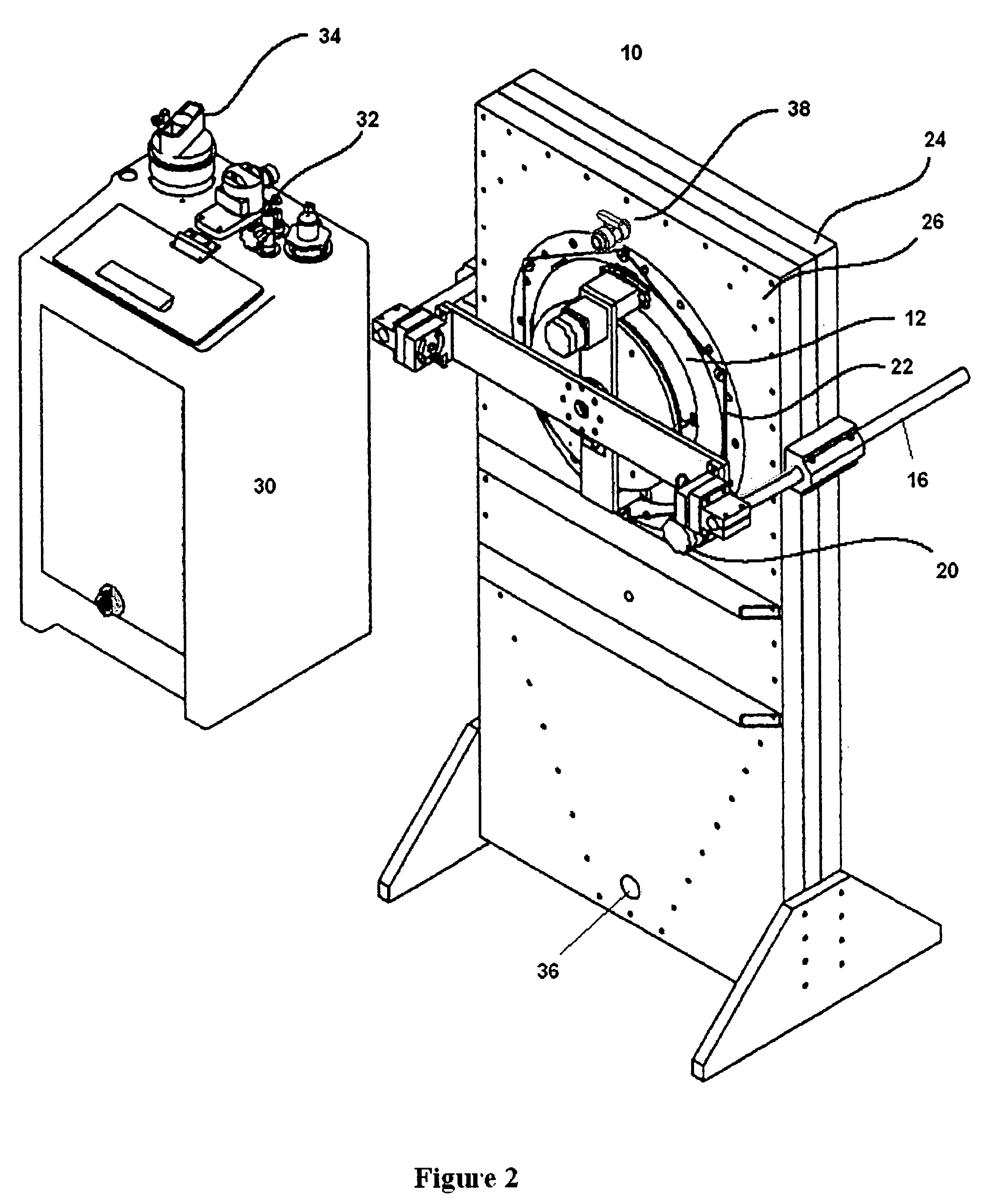

[0048] The present invention is of an apparatus and method for highly controlled electrodeposition, particularly useful for electroplating submicron structures. Enhanced control of the process provides for a more uniform deposit thickness over the entire substrate, and permits reliable plating of submicron features, for example those on a semiconductor wafer. A primary advantage of the invention is that the kinetics of the cell, which are based on the geometries of the cell, can be changed quickly to optimize plating on the substrate surface, for all deposits including very thick film deposits and thin film deposits.

[0049] As used throughout the specification and claims, "substrate" means any substrate, wafer, lens, panel, and the like, or any other item which is to be attached to an electrode to be plated. Such substrate may comprise any material such as a semiconductor, including but not limited to silicon, gallium arsenide, sapphire, glass, ceramic, metal alloy, polymer, or photo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com