Electric heating concrete plate for heating and preparation method thereof

A concrete and plate technology, applied in the field of conductive concrete, can solve the problems of uneven heating, increase the floor load, and reduce the net height, and achieve the effects of improving the uneven heating, reducing the floor load and reducing the net height.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] A second aspect of the present invention discloses a method for preparing an electric heating concrete slab for heating described in the first aspect of the present invention, comprising the following steps:

[0036] S1: Add the conductive material and water into the mixing tank, start stirring, and evenly disperse the conductive material in the water;

[0037] S2: mix cement, heat-conducting aggregate, ordinary aggregate, early strength agent, water reducer, and defoamer uniformly in proportion to obtain mixed powder;

[0038] S3: Add the mixed powder obtained in S2 into the mixing tank in S1 and stir evenly to obtain conductive concrete mortar;

[0039] S4: Pouring the conductive concrete mortar obtained in S3 into a mold with electrodes at both ends with a height of 10mm, and curing it for 28 days in a humid environment at room temperature to obtain an electrothermal concrete plate with a thickness not greater than 10mm, a length of 800mm, and a width of 400mm.

[0...

Embodiment 1

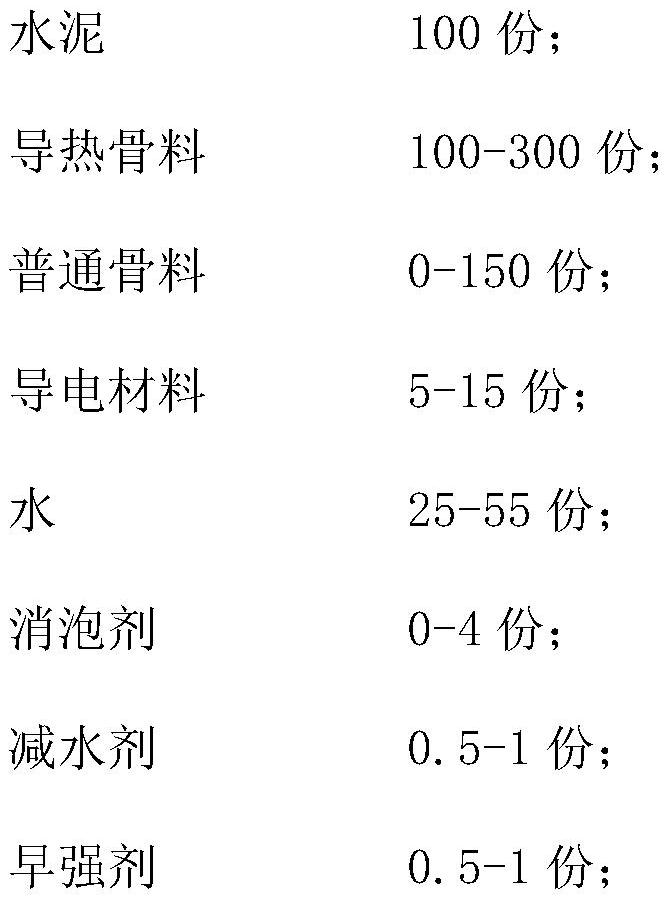

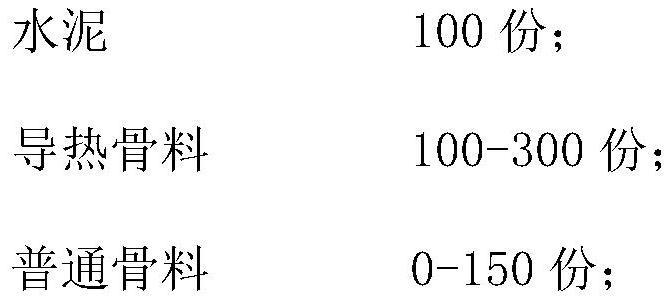

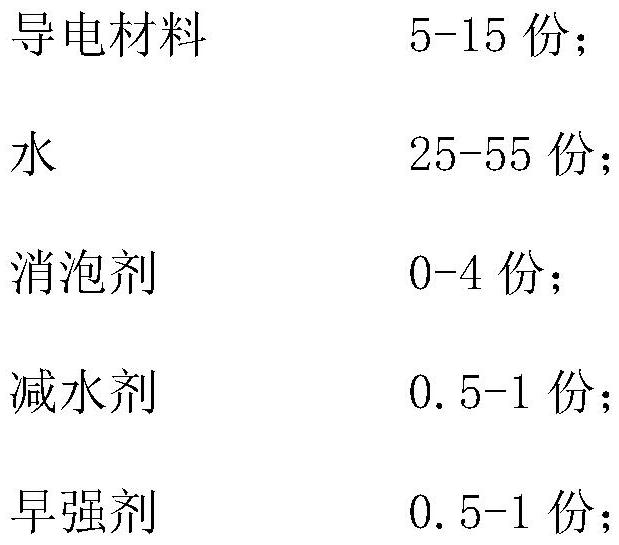

[0055] An electrothermal concrete for heating, comprising the following raw materials in parts by weight:

[0056] 42.5 Portland cement: 100 parts

[0057] Graphene: 1.5 parts

[0058] Conductive carbon black: 9.5 parts

[0059] 1-3mm white corundum: 67 parts

[0060] 0.15-1mm corundum: 33 parts

[0061] 0.15-1.5 river sand: 40 parts

[0062] 1-4mm gravel: 60 parts

[0063] Calcium acetate: 0.5 parts

[0064] Calcium formate: 0.25 parts

[0065] Water reducing agent: 0.5 parts

[0066] Defoamer: 0.3 parts

[0067] Water: 45 parts.

[0068] A method for preparing electric heating concrete for heating comprises the following steps:

[0069] S1: Add graphene, conductive carbon black and water into the mixing tank according to the above weight parts, start stirring, so that graphene and conductive carbon black are evenly dispersed in the water;

[0070] S2: Mix 42.5 Portland cement, white corundum, corundum, river sand, crushed stone, calcium acetate, calcium formate, w...

Embodiment 2

[0075] An electrothermal concrete for heating, comprising the following raw materials in parts by weight:

[0076] 42.5 Portland cement: 100 parts

[0077] Graphene: 2 parts

[0078] Conductive carbon black: 8 parts

[0079] 1-3mm white corundum: 80 parts

[0080] 0.15-1mm corundum: 120 parts

[0081] 0.15-1.5 river sand: 60 parts

[0082] 1-4mm gravel: 90 parts

[0083] Calcium acetate: 0.5 parts

[0084] Calcium formate: 0.5 parts

[0085] Water reducing agent: 0.5 parts

[0086] Defoamer: 0.3 parts

[0087] Water: 40 parts.

[0088] A method for preparing electric heating concrete for heating comprises the following steps:

[0089] S1: Add graphene, conductive carbon black and water into the mixing tank according to the above weight parts, start stirring, so that graphene and conductive carbon black are evenly dispersed in the water;

[0090] S2: Mix 42.5 Portland cement, white corundum, corundum, river sand, crushed stone, calcium acetate, calcium formate, water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com