Fiber heat treatment reaction device, heat treatment system and heat treatment method

A technology of heat treatment reaction and heat treatment system, which is applied in the field of heat treatment of polyarylate fibers, can solve problems such as low efficiency of heat treatment equipment, huge energy consumption of equipment, and restrictions on the industrialization progress of liquid crystal polyarylate fibers, so as to improve production and heat treatment efficiency , Improve the effect, increase the output and the effect of heat treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] At present, the preparation of liquid crystal polyarylate fiber is still in the research stage in China, and the relevant research is as follows:

[0054] CN104746155A introduces a thermotropic liquid crystal polyarylate monofilament heat treatment device and a heat treatment method thereof. The method is only for monofilament, and the treatment condition is heat treatment in a heated vacuum airtight box, and the heat treatment efficiency is low. At the same time, an unwinding roller, a heating tension roller and a winding roller are sequentially arranged in the box, and the fibers are dynamically heat-treated in the box. Such a structure makes the whole equipment huge, so the energy consumption and cost of the whole heat treatment are high.

[0055] CN106087177B introduces a continuous solid-state polycondensation heat treatment method for liquid crystal polyester fibers. The method adopts a plurality of high and low temperature chambers to carry out continuous heat tre...

Embodiment 1

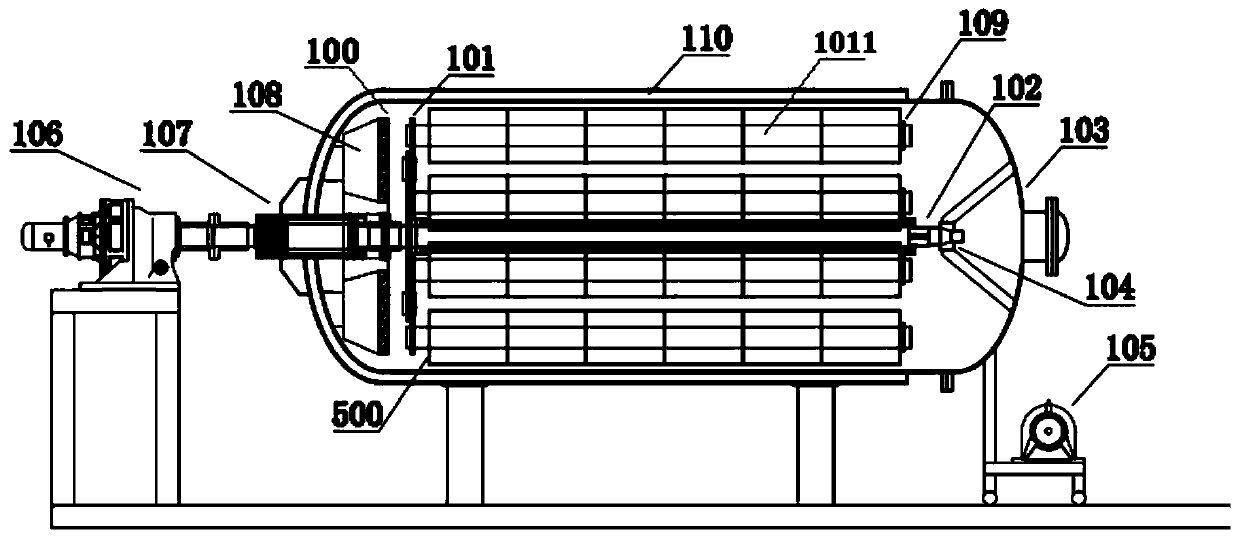

[0062] This embodiment provides a heat treatment reaction device, see Figure 1-4 , comprising a reactor body 100, the reactor body 100 is provided with a central axis 102, a tow carrying device 101 and a gas spray device 108, the tow carrying device 101 is arranged on the central axis 102, the The central shaft 102 is connected to an external drive mechanism.

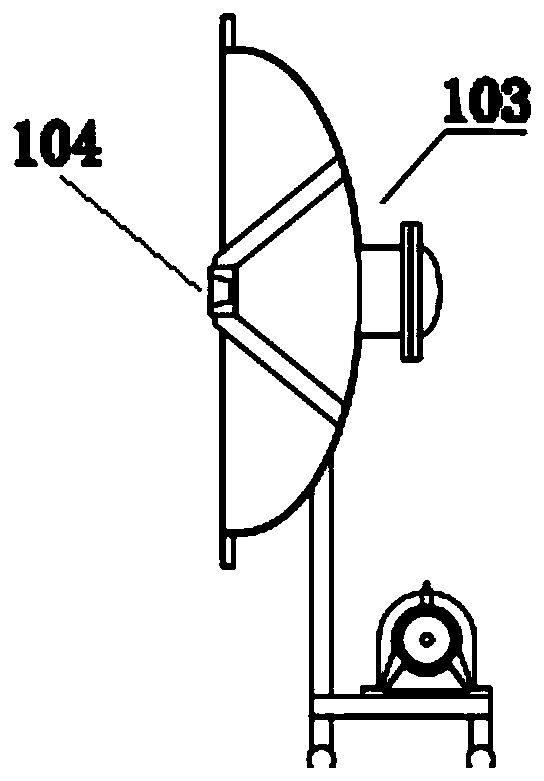

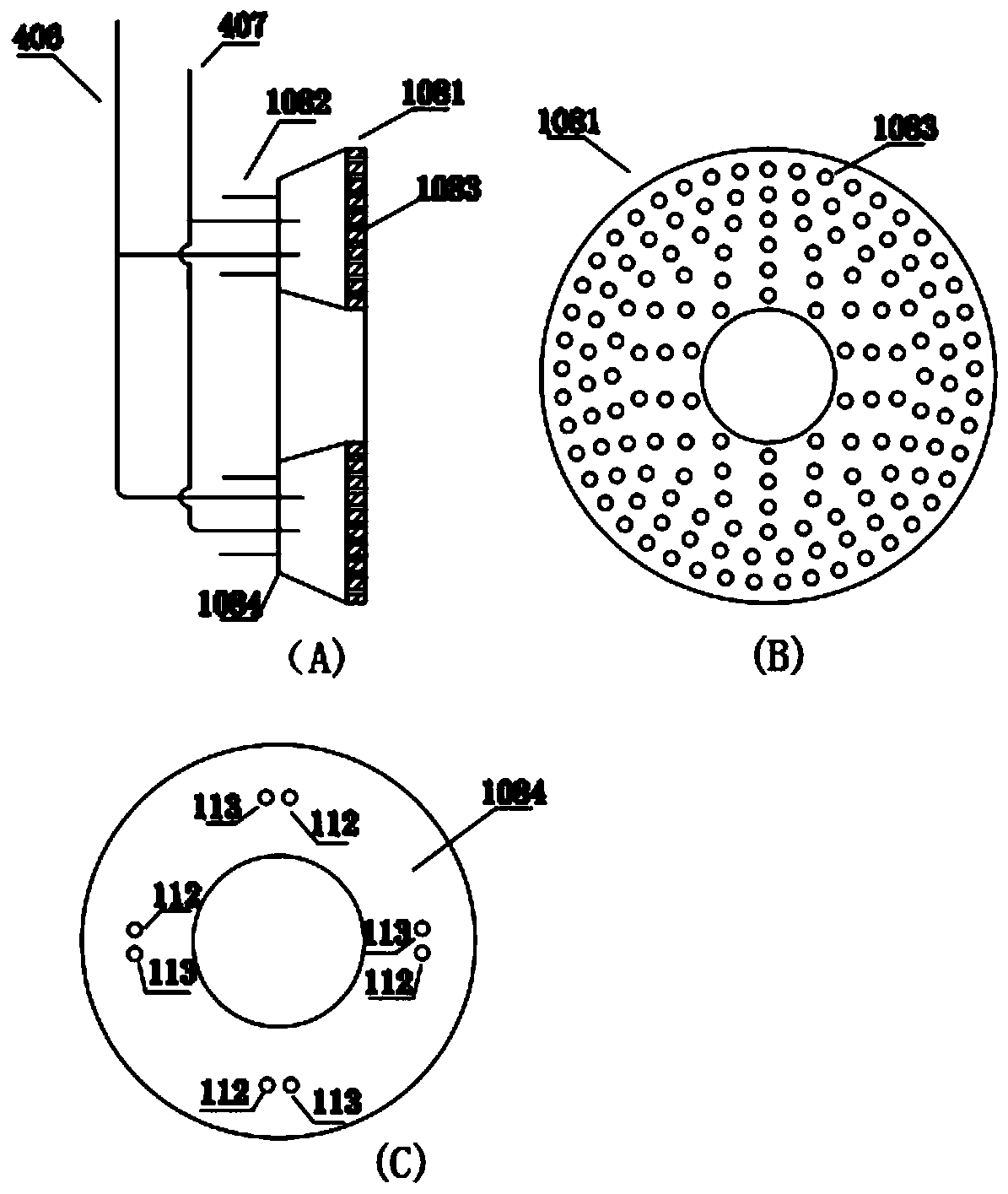

[0063] Specifically, the reaction kettle body 100 is a horizontal tank body, and the gas spray device 108 is a spray plate, which is arranged between the reaction kettle body 100 and the tow carrying device 101 . The central axis 102 is connected to the end of the horizontal tank body and extends toward the inside of the reactor body 100, the other end is provided with a kettle door 103, and the inside of the kettle door 103 is provided with a central axis positioning member 104, It is used for the alignment of the distal end of the central shaft 102 to make the rotation stable.

[0064] Described drive mechanism com...

Embodiment 2

[0074] This embodiment provides a heat treatment system that can be used for heat treatment of polyarylate fibers. see Figure 5 , Fig. 6, including heat treatment reaction device, said heat treatment reaction device is respectively connected with heating and cooling system, vacuum system and nitrogen system. The heat treatment reaction device is the reactor body 100 described in Example 1.

[0075] Specifically, the heating and cooling system includes a heating system and a cooling system. The heating system includes a heat conduction oil heating tank 201, an oil pump 202, and an oil-gas separator 203 connected in sequence, and also includes a heating control unit. The heating control unit mainly includes A controller is electrically connected to the heater inside the heat conduction oil heating tank 201, and the heating control unit controls the heating to start and stop. The coil outlet 115 of the annular coil type oil passage interlayer 110 of the reactor body 100 is con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com