Sliding valve type two-mode engine intake valve delaying shutdown system

A delayed shutdown and engine technology, applied to engine components, machines/engines, valve devices, etc., can solve the problems of difficult exhaust valve adjustment, low manufacturing cost, etc., and achieve low power consumption, long service life, and system components little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

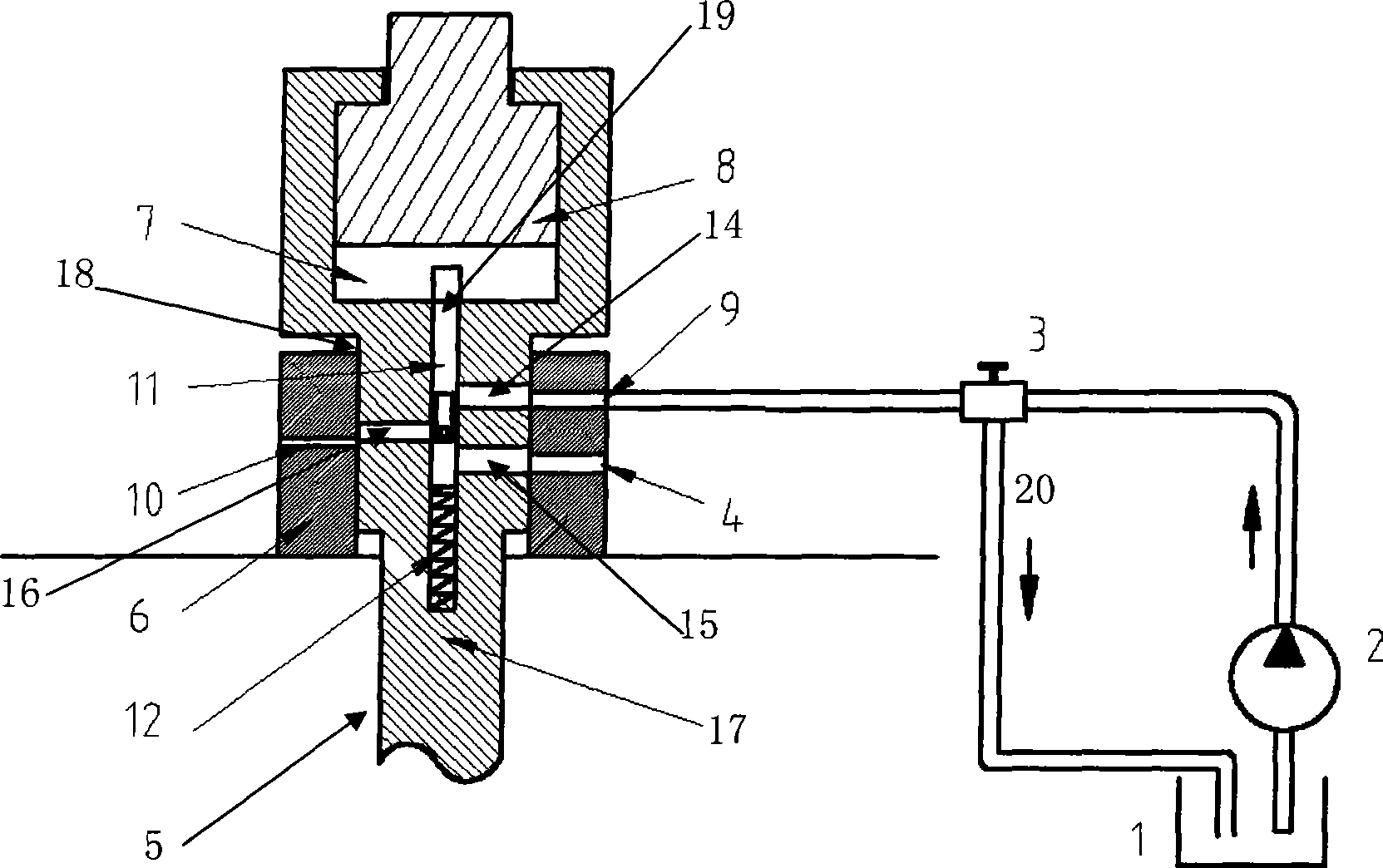

[0027] The slide valve type two-mode engine intake valve delay closing system of the present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings.

[0028] Such as figure 1 As shown, the spool type two-mode engine intake valve delay closing system of the present invention is a valve delay closing system controlled by a mechanical slide valve and utilizing the expansion and contraction of the hydraulic lifter assembly to realize valve phase adjustment. It includes: a base 6 and a hydraulic lifter assembly 5 that slides up and down along the base 6, and the top end is connected to the valve, and the bottom end is connected to the engine. It is characterized in that an oil supply system for supplying oil to the hydraulic lifter assembly 5 is also provided 13. The hydraulic tappet assembly 5 is formed with an assembly oil inlet hole 14 and an assembly drain hole; the base 6 is formed with one end communicating with the oil s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com