Conductive rubber material for flexible sensor and preparation method and application of conductive rubber material

A flexible sensor and conductive rubber technology, applied in the field of flexible sensors, can solve the problems of poor flexibility and complex structure of strain sensors, and achieve the effects of achieving consistency, simple and controllable methods, and high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

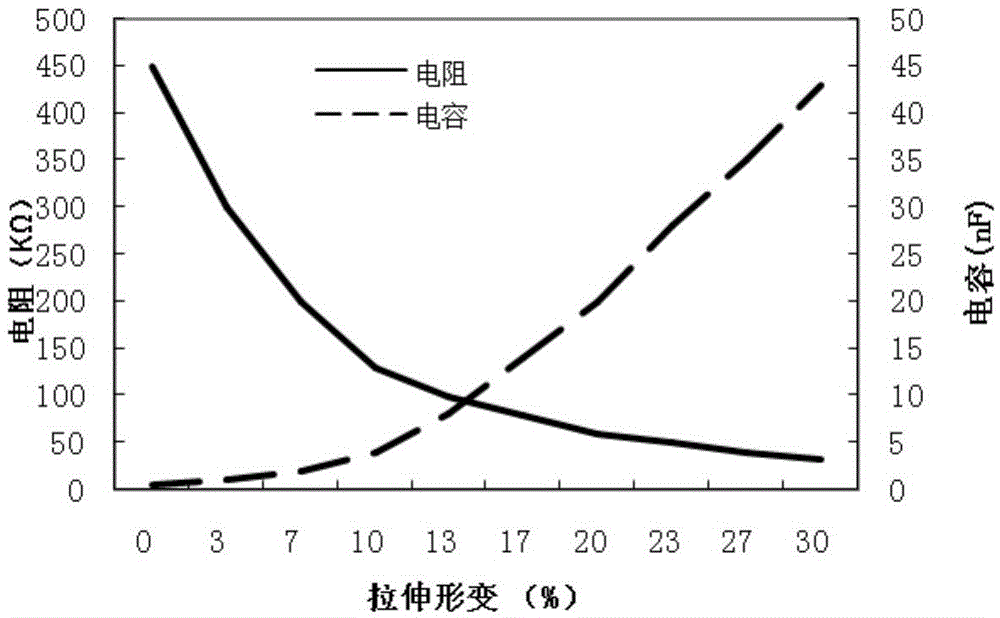

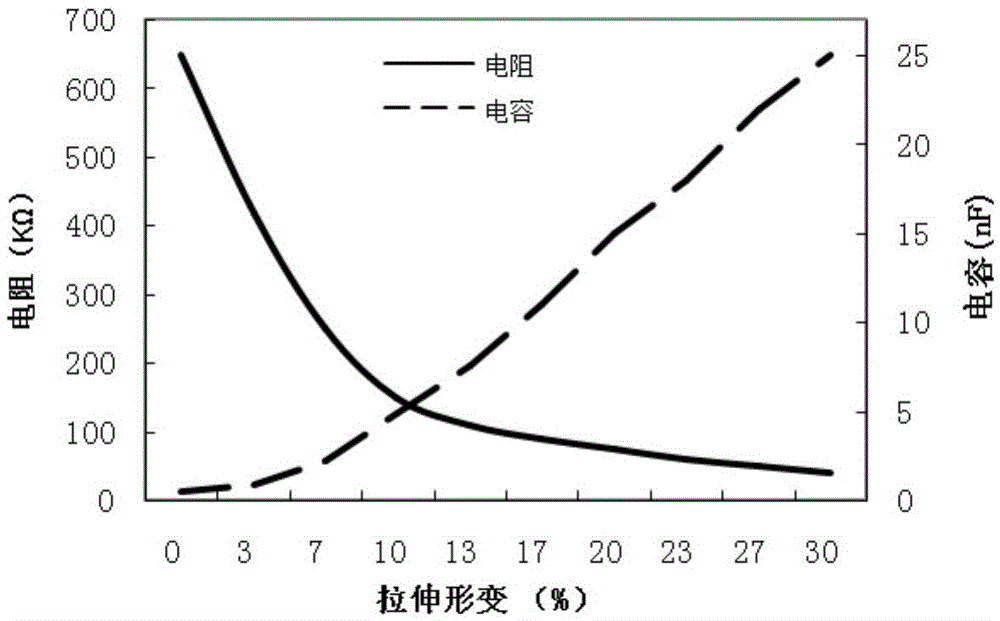

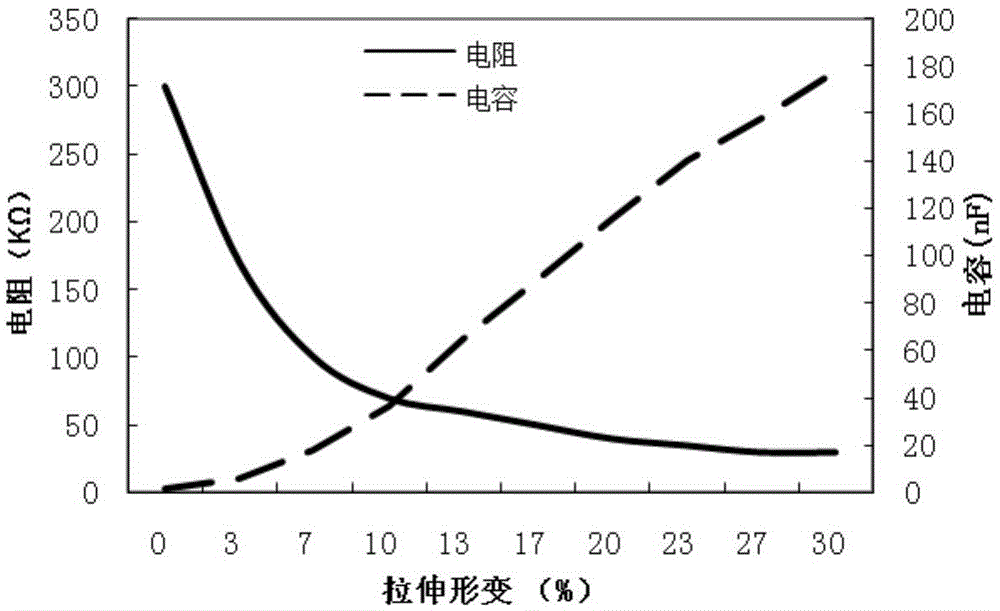

[0067] The preparation method of the conductive rubber material described in the embodiment of the present invention adopts electron beam or γ-ray radiation for cross-linking, and the degree of cross-linking of the rubber can be regulated arbitrarily by controlling the absorbed dose, and the electron beam or γ-ray can penetrate the rubber glue layer , so that the overall cross-linking degree of the rubber is consistent and uniform; when the rubber conductive material is used as the sensor sensitive unit material, the consistency of the distribution of the resistance value of the strain sensor can be achieved, especially the change of electrical signals such as resistance and capacitance under the action of external force Sensitivity, stability, recovery and other properties. In addition, the method of the embodiment of the present invention is simple and controllable, and is easy to realize industrialization.

[0068] And, a strain sensor includes a sensitive unit and metal el...

Embodiment 1

[0077] A kind of conductive rubber material for flexible sensor, comprising each content component described in the embodiment 1 of table 1, and described conductive rubber material is by dispersing conductive filler in rubber material, through electron beam or gamma ray radiation exchange Jointly made.

[0078] And, the preparation method of the conductive rubber material for the flexible sensor includes the following steps:

[0079] S11. Weigh each component according to the above formula for the conductive rubber material of the flexible sensor;

[0080] S12. Add the rubber matrix and the conductive filler into the open mill for mixing, and the mixing time is 20 minutes. After the various fillers are mixed evenly, the sheets are thinned out to obtain the mixed rubber;

[0081] S13. Molding the mixed rubber with a rubber plate vulcanizer to obtain a sheet rubber material, the size of the sheet rubber material is 100 mm in length x 100 mm in width x 1 mm in thickness;

[0082...

Embodiment 2

[0085] A kind of conductive rubber material for flexible sensor, comprising each content component described in the embodiment 2 of table 1, and described conductive rubber material is made by dispersing conductive filler in rubber material, through electron beam or gamma ray radiation exchange Jointly made.

[0086] And, the preparation method of the conductive rubber material for the flexible sensor includes the following steps:

[0087] S21. Weigh each component according to the above formula for the conductive rubber material of the flexible sensor;

[0088] S22. Add the rubber matrix and the conductive filler into the open mill for mixing, the mixing time is 20min, and after the various fillers are mixed evenly, the sheets are thinned out to obtain the mixed rubber;

[0089] S23. Molding the mixed rubber with a rubber flat vulcanizer to obtain a sheet rubber material, the size of the sheet rubber material is 100 mm in length x 100 mm in width x 1 mm in thickness;

[009...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com