Pull-sensitivity sensor with negative resistance effect and manufacturing method thereof

A manufacturing method and sensor technology, applied in the direction of instruments, measuring devices, measuring force, etc., can solve the problems of small change range of mechanical force, inability to bend, lack of flexibility and elasticity, etc., and achieve large change range of force force, excellent flexibility and elasticity , the effect of good stability performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

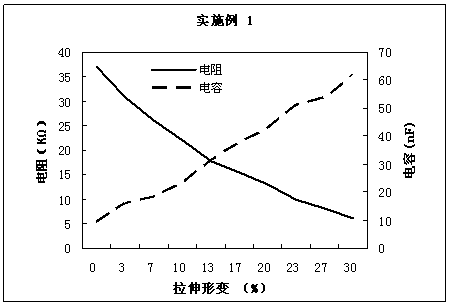

Embodiment 1

[0030] The pull-sensitivity sensor with negative resistance effect of the present embodiment adopts conductive natural rubber as the pull-sensitivity material, and its manufacturing method is as follows:

[0031] The composition ratio and production method of conductive rubber are as follows:

[0032] In the following order, 100 parts by mass of natural rubber NR (brand SCR5, Hainan rubber), 1 part by mass of antioxidant D (chemical name: diphenylguanidine), carbon black (Raven520U, particle size 58nm, oil absorption value 120m 2 / g, Columbia Chemicals) 120 parts by mass, sequentially added to a two-roll mill for mixing, the temperature of the mill was set at 50°C, and after the components were mixed evenly, the thin sheets were discharged. Put the kneaded conductive natural rubber into a mould, and mold it at 130° C. under a pressure of 15 MPa for 10 minutes to obtain a semi-finished conductive rubber with a thickness of 1 mm.

[0033] The natural rubber semi-finished produc...

Embodiment 2

[0065] combine figure 2 , according to the same method as in Example 1 to manufacture the pull-sensitive electric sensor of negative resistance effect, but with 110 mass parts of carbon black (Raven520U, particle diameter 58nm, oil absorption value 120m 2 / g, Columbia Chemical) replaces the carbon black (Raven520U, particle diameter 58nm, oil absorption value 120m 2 / g, Columbia Chemicals). The properties of the pull-sensitivity sensor were tested in the same manner as described in Example 1, and the results are listed in Table 2.

Embodiment 3

[0067] combine image 3 , according to the same method as in Example 1 to manufacture the pull-sensitivity sensor of negative resistance effect, but with 100 mass parts of carbon black (Raven520U, particle diameter 58nm, oil absorption value 120m 2 / g, Columbia Chemical) replaces the carbon black (Raven520U, particle diameter 58nm, oil absorption value 120m 2 / g, Columbia Chemicals). The properties of the pull-sensitivity sensor were tested in the same manner as described in Example 1, and the results are listed in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com