Phase-change buoyancy engine based on microwave heating

A microwave heating and buoyancy technology, which is applied to special-purpose ships, underwater operation equipment, ships, etc., can solve the problems of reducing the response speed of phase-change buoyancy engines and heating wires that cannot be heated, so as to improve uneven heating, ensure speed, The effect of increasing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing.

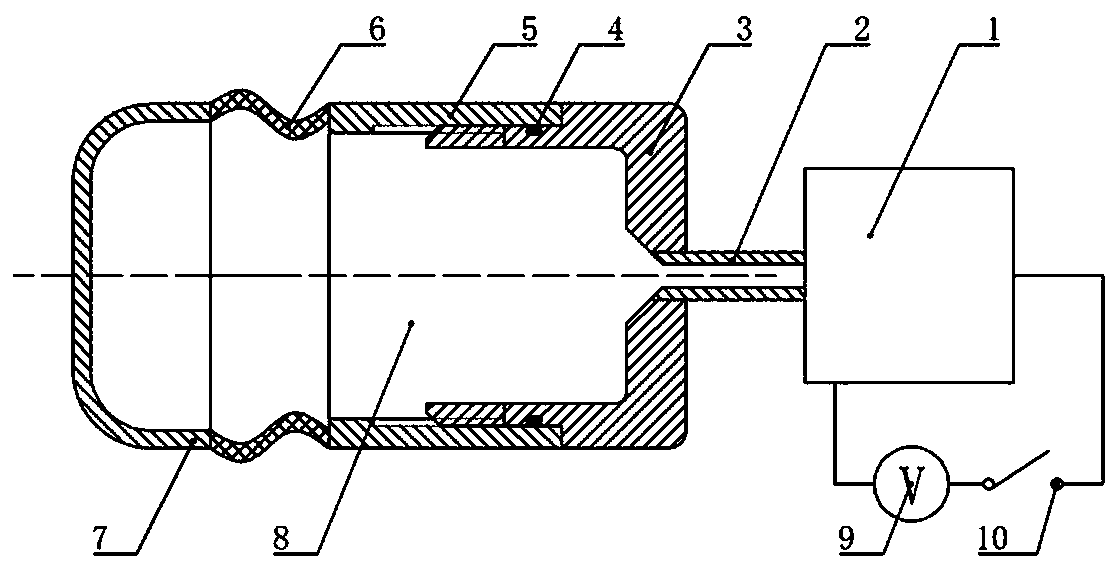

[0017] Such as figure 1 Shown, the phase-change buoyancy engine utilizing microwave heating of the present invention is made up of buoyancy generation unit and temperature control unit, and wherein buoyancy generation unit is made up of base 3, sealing ring 4, connecting ring 5, soft ring 6, end cover 7, phase Variable material 8 constitutes. The temperature control unit is composed of a magnetron 1 , a filter conduit 2 , a power supply 9 and a switch circuit 10 .

[0018] Base 3, connecting ring 5 and end cap 7 are made of metal, and soft ring 6 is made of soft material. The base 3 and the connecting ring 5 are threaded together, and the inner side of the connecting ring 5 is sealed waterproofly with the sealing ring 4; the soft ring 6 is glued together with the connecting ring 5 and the end cap 7 respectively; 6. A cavity is formed inside the end cap 7, and the phase c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com