Fin type pulsating heat pipe phase change energy storage integrated module and application

A technology of phase change energy storage and pulsating heat pipes, which is applied in the field of heating devices, can solve the problems of large thermal inertia and high system water supply temperature, and achieve the effects of improving thermal inertia, reducing high water supply temperature, and improving uneven heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

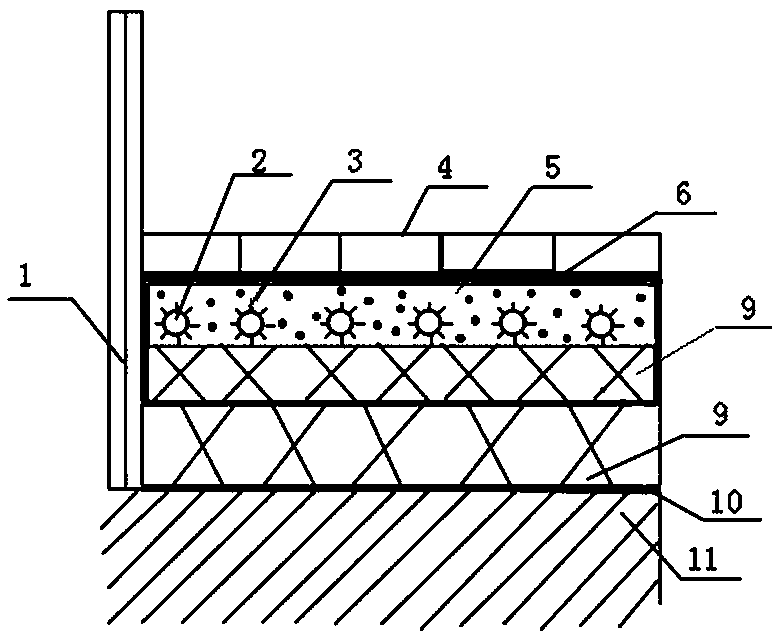

[0015] Below in conjunction with accompanying drawing, the present invention will be further described:

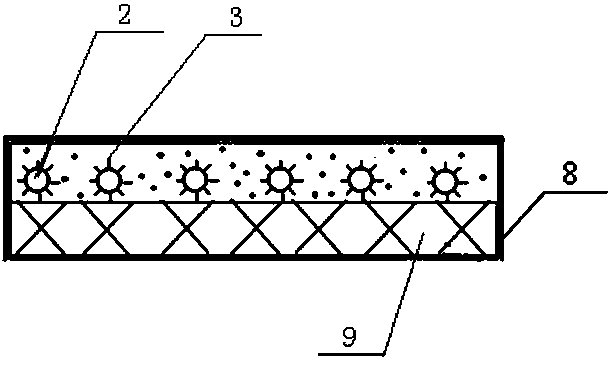

[0016] combine figure 1 As shown, this rib-type pulsating heat pipe phase change energy storage integrated module includes a steel plate box 8, which is composed of stainless steel plates, and the lower layer of the steel plate box 8 is laid with a polyurethane insulation layer. 2. The pulsating heat pipe 2 is covered with ribs 3 for enhancing heat transfer, the steel box 8 is filled with phase change energy storage materials, and the upper end of the steel box 8 is sealed with an aluminum plate 7 .

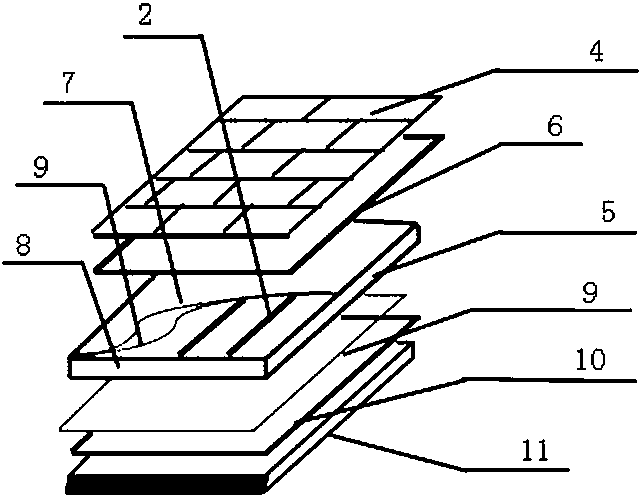

[0017] refer to figure 2 , image 3 , the finned pulsating heat pipe phase change energy storage integrated module of the present invention is used to make the finned pulsating heat pipe phase change energy storage floor, and the finned pulsating heat pipe phase change energy storage floor is as follows from bottom to top: dehumidification and dehumidification layer , the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com