White smoke elimination system for blast furnace slag flushing dead steam

A technology of blast furnace slag flushing and slag flushing, which is applied in the whitening system of blast furnace slag flushing and exhausted steam, and the whitening system field of blast furnace slag flushing exhausted steam "source dehumidification + condensation dehumidification + cyclone dehydration", which can solve corrosion, Waste of water resources, environmental pollution and other issues, to achieve the effect of enhancing heat and mass transfer and increasing exhaust steam stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

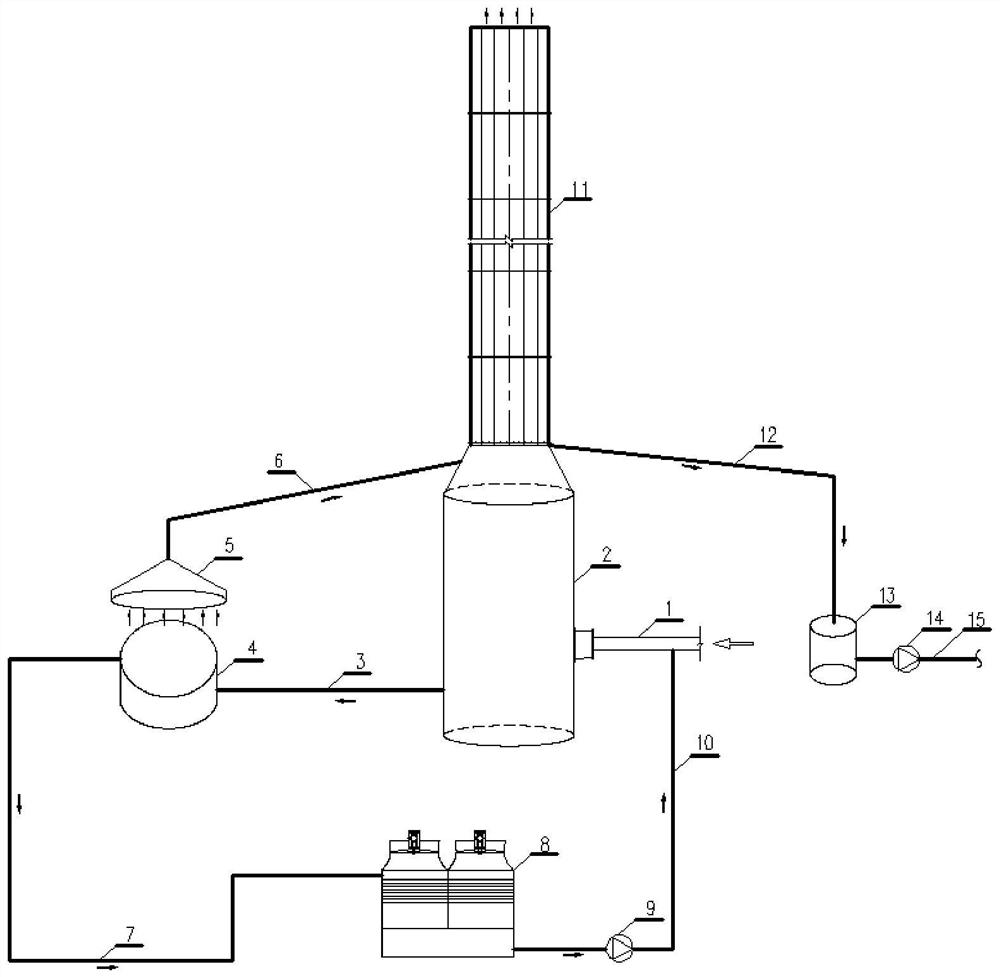

[0020] A blast furnace slag flushing waste steam "source dehumidification + condensation dehumidification + cyclone dehydration" whitening system, characterized in that it mainly includes a slag ditch 1, a granulation tower 2, a granulation tower outlet water pipeline 3, and a stirring cage 4 , Stirring cage sealing cover 5, exhaust steam pipeline 6, stirring cage outlet water pipeline 7, cooling tower 8, slag flushing water supply pump 9, slag flushing water supply pipeline 10, environmental protection condensation dehumidification and whitening device 11, condensed water collection pipeline 12. Condensed water tank 13, condensed water pressurized pump 14, condensed water conveying pipeline 15, the blast furnace slag is connected to the granulation tower 2 along the slag ditch 1, and the granulation tower 2 is connected with the environmental protection condensation dehumidification through variable diameter The inlet of the whitening device 11 is connected, the outlet water p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com