Heat pump unit

A technology of heat pump units and components, which is applied in heat pumps, refrigerators, refrigeration components, etc., can solve the problems of insufficient cooling capacity of the return water of the primary network, limited heat of the condenser, and increased volume of the unit, achieving reasonable structure and reduced volume , small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

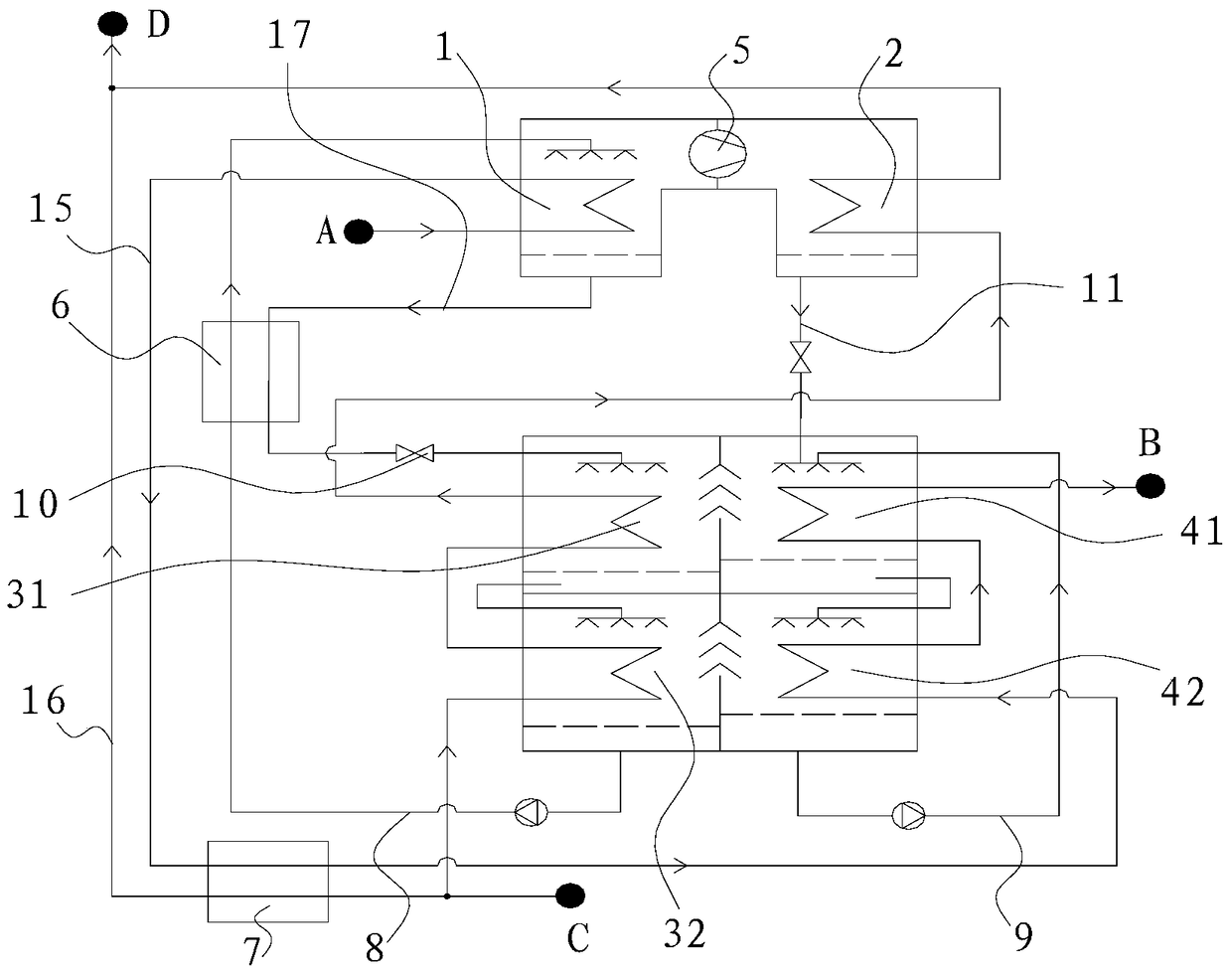

[0024] This preferred embodiment discloses a heat pump unit. Such as figure 1 As shown, the heat pump unit includes a generator 1 and a condenser 2 arranged adjacently, and an absorber assembly and an evaporator assembly adjacently arranged. Wherein, a water vapor compressor 5 is arranged between the generator 1 and the condenser 2; the absorber assembly includes a first absorber 31 and a second absorber 32 connected in series, and the first absorber 31 and the second absorber 32 The pipes are connected to form a passage, and the shells of the first absorber 31 and the second absorber 32 are communicated; the evaporator assembly includes a first evaporator 41 and a second evaporator 42 connected in series, and the first evaporator 41 and the second evaporator The pipes of the second evaporator 42 are connected to form a channel, the shells of the first evaporator 41 and the second evaporator 42 are connected, and a refrigerant water circulation pipeline 9 is provided.

[002...

Embodiment 2

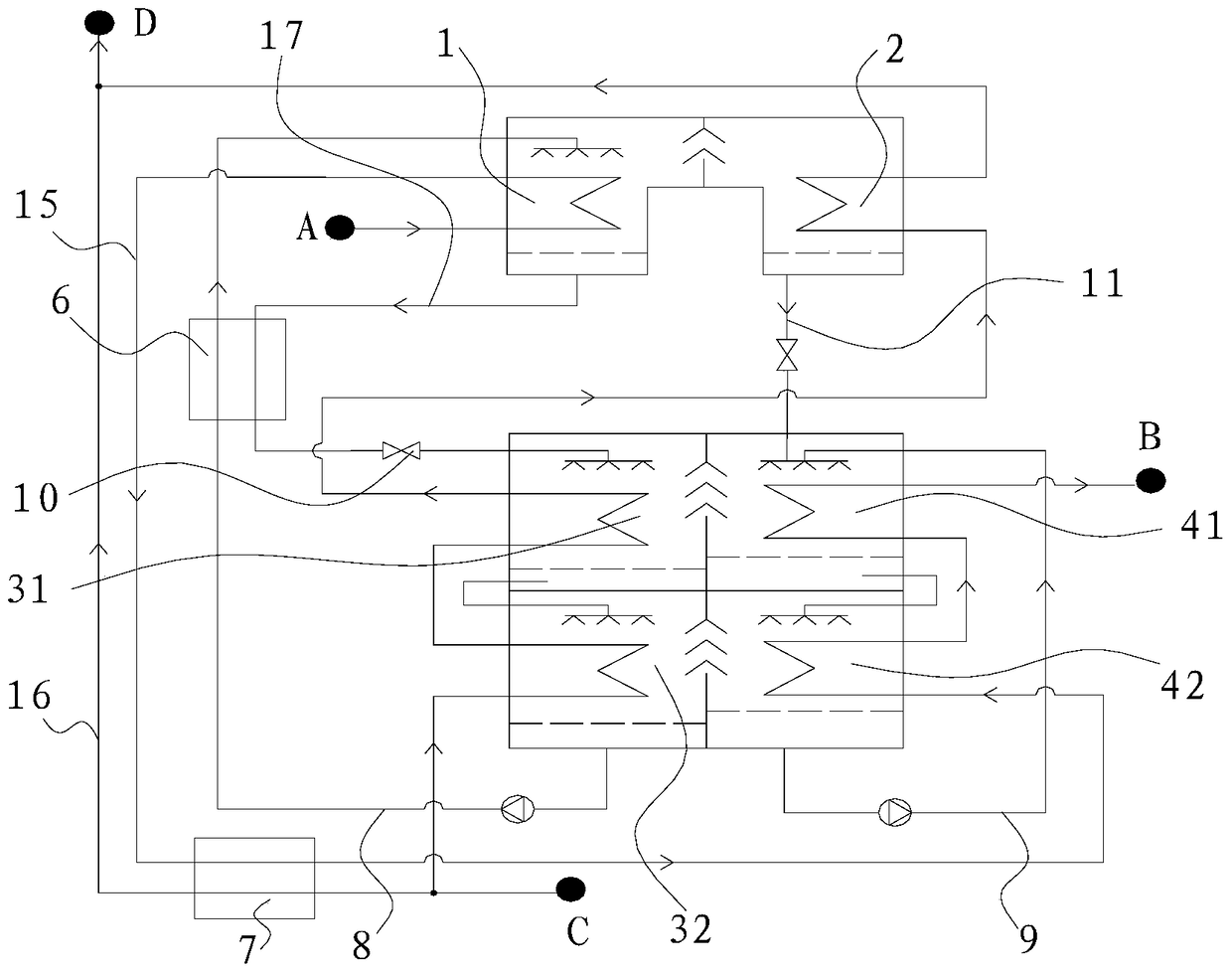

[0033] This preferred embodiment discloses a heat pump unit whose structure and working method are basically the same as those of the first preferred embodiment. The difference is that: if figure 2As shown, there is no steam compressor 5 between the generator 1 and the condenser 2 . In operation, the aqueous solution in the housing of the generator 1 evaporates to form water vapor which enters directly into the housing of the condenser 2 .

Embodiment 3

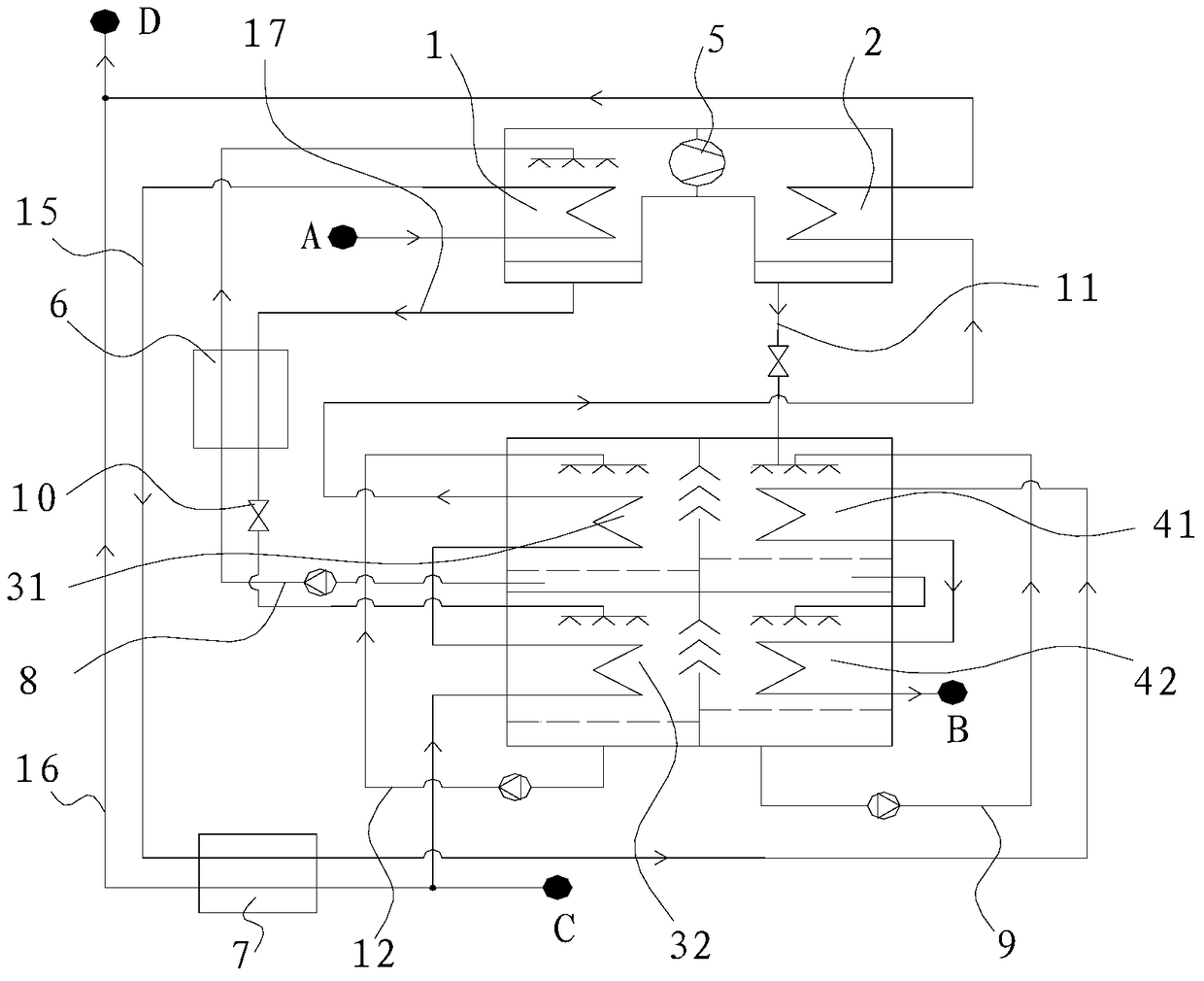

[0035] This preferred embodiment discloses a heat pump unit whose structure and working method are basically the same as those of the first preferred embodiment. The difference is that: if image 3 As shown, the shell of the second absorber 32 is connected to the shell of the first absorber 31 through the solution circulation pipeline 12, and the first branch 8 of the solution is connected between the shell of the generator 1 and the shell of the first absorber 31, The solution second branch 17 is connected between the shell of the generator 1 and the shell of the second absorber 32; the primary water pipe 15 is connected to the outlet end of the pipeline of the generator 1 and the pipeline inlet end of the first evaporator 41, and the primary water outlet B is provided at the pipe outlet end of the second evaporator 42 .

[0036] Correspondingly, the difference in the working method is: the solution in the shell of the second absorber 32 heats the secondary water in the pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com