Conformal water-cooling mold for indirect thermal forming production line

A thermoforming and production line technology, applied in the direction of forming tools, manufacturing tools, heat treatment equipment, etc., which can solve the problems of inability to fit complex cross-sections, fixed structures, and unbalanced local temperature distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

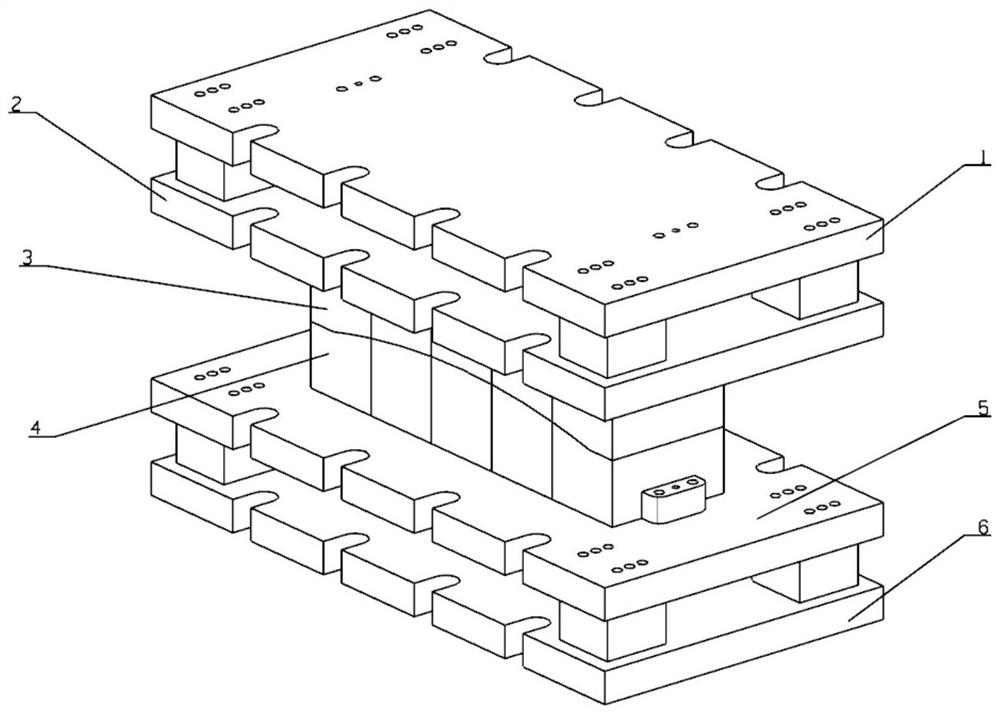

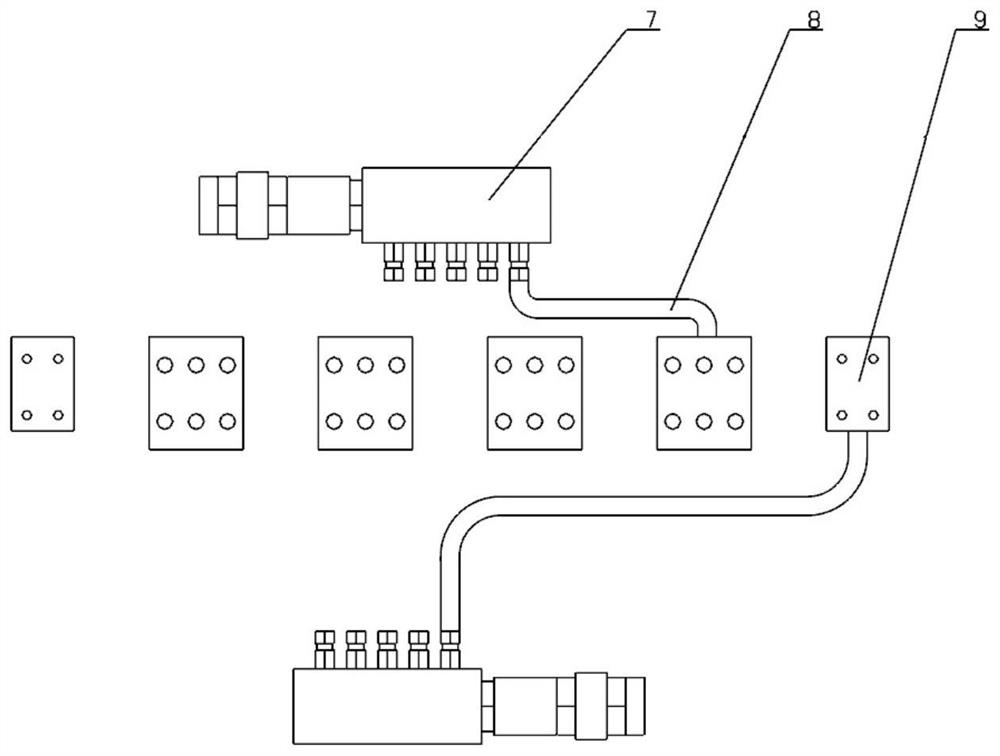

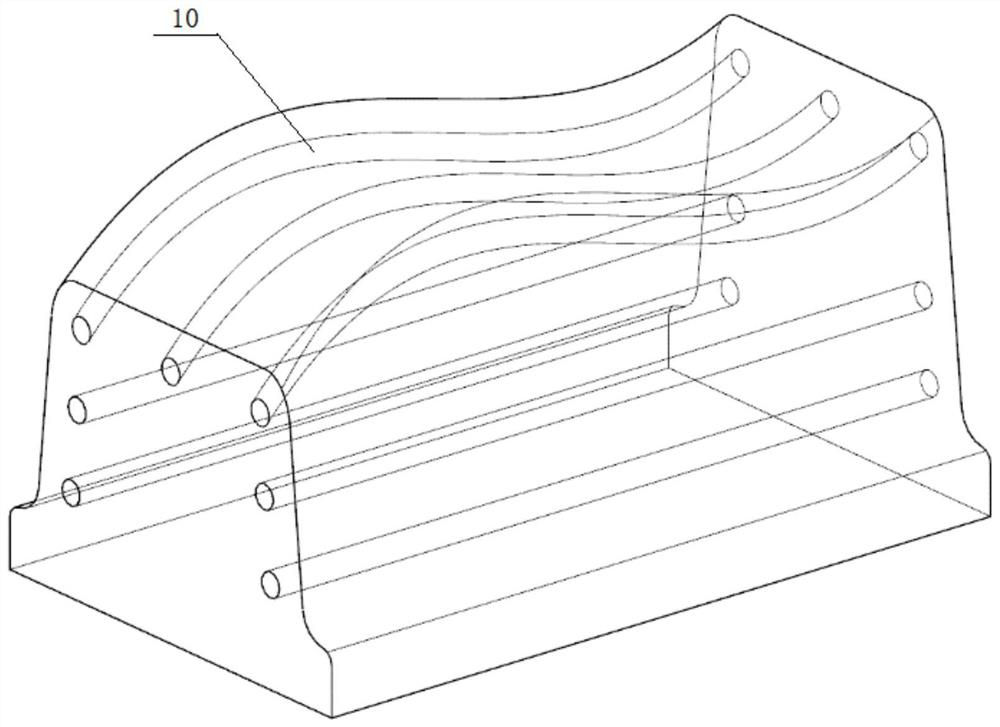

[0023] see Figure 1-3 , a conformal water-cooled mold used in an indirect thermoforming production line, comprising an upper die base plate 1 and a lower die base plate 6, an upper die mounting plate 2 is fixedly connected to the bottom surface of the upper die base plate 1, and the bottom surface of the upper die mounting plate 2 A thermoforming upper die 3 is connected to the upper part; a lower die mounting plate 5 is fixedly connected to the top surface of the bottom plate 6 of the lower die, and a thermoforming lower die 4 is connected to the top surface of the lower die mounting plate 5. According to the shape characteristics of the thermoforming parts, the The thermoforming upper die 3 is set as a concave die, and the thermoforming lower die 4 is set as a convex die; an upper die mounting cavity is arranged between the upper die base plate 1 and the upper die mounting plate 2, and the lower die base plate 6 and the lower die mounting plate 5 A lower mold installation c...

Embodiment 2

[0030] see Figure 1-3 , based on Embodiment 1, the difference is that;

[0031] The main equipment of the indirect thermoforming process includes: cold stamping line, automatic handling system, thermoforming press, heating furnace, and water-cooled mold.

[0032] In the production line, the blanking, preforming, trimming and punching of the sheet are first completed on the ordinary cold stamping line, and then coated with high-temperature anti-oxidant, placed in the heating furnace by the manipulator to complete the austenitization of the material, and then passed through The manipulator is quickly placed on the thermoforming mold fixed with the press for forming. After forming, it is cleaned and oiled for storage.

[0033] Such as figure 1 As shown, the upper mold bottom plate 1 is fixed to the upper worktable of the thermoforming press with a standard T-shaped slot by bolts, and the lower mold bottom plate 6 is fixed to the lower worktable of the thermoforming press. Take ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com