Heat treatment device for elastic titanium-nickel alloy glasses leg linear blank

A heat treatment device, titanium-nickel alloy technology, applied in the direction of heat treatment furnace, heat treatment equipment, furnace type, etc., can solve the problems of affecting the heat treatment effect, poor elasticity of glasses legs, hindering heat conduction, etc., to achieve uneven heating and convenient Observation, the effect of low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

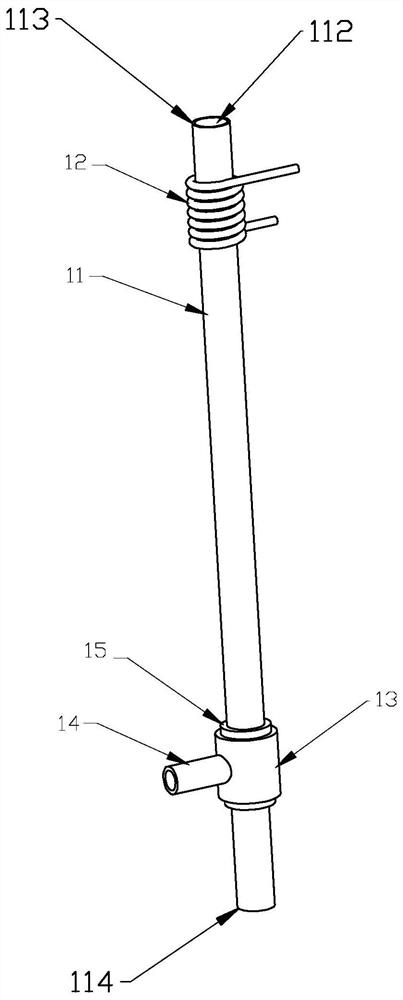

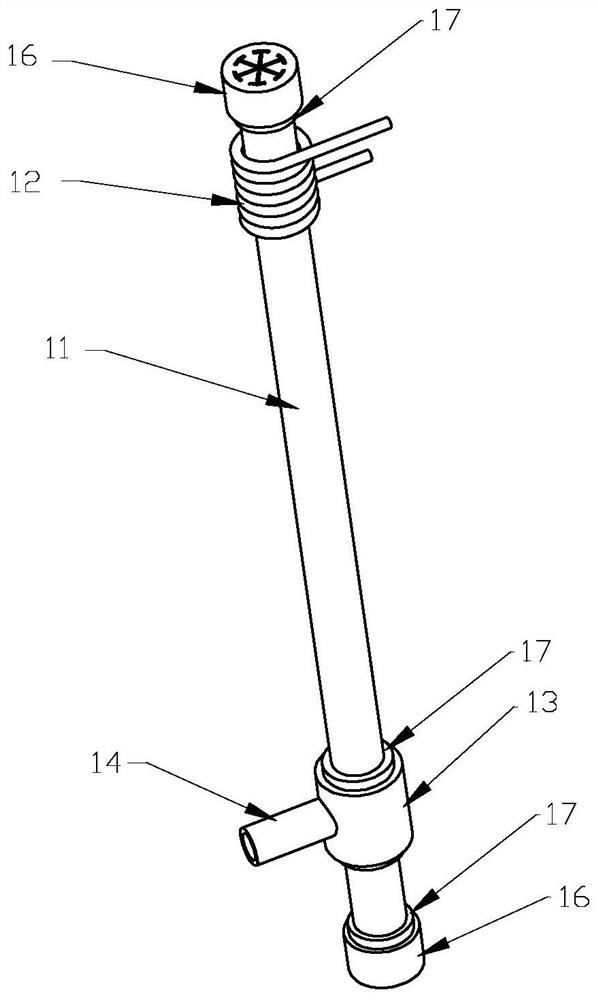

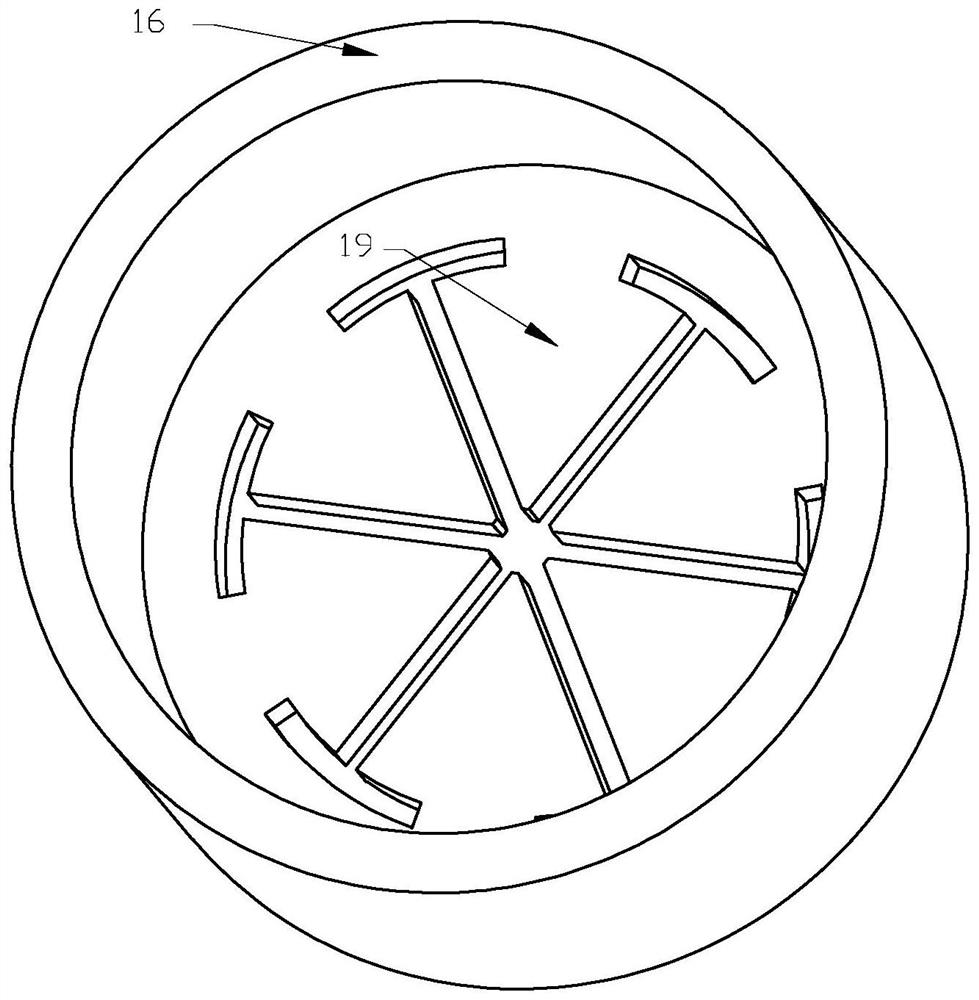

[0022] Below in conjunction with accompanying drawing, the present invention is introduced in detail, as Figure 1-3 As shown, a heat treatment device for elastic titanium-nickel alloy spectacle leg linear blanks, the heat treatment device includes a heat-resistant glass tube 11, a high-frequency coil 12 and a protective gas introduction device 13, the heat-resistant glass tube 11 is vertical It is arranged vertically, and is provided with a through hole 112 along the axial direction. The through hole 112 includes a material inlet 113 and a material outlet 114. The high frequency coil 12 is wound on the outer peripheral surface of the heat-resistant glass tube 11. The protective gas introduction device 13 communicates with the through hole 112.

[0023] The protective gas introduction device 13 is arranged on the side of the discharge port 114 of the heat-resistant glass tube 11, sleeved on the outer periphery of the heat-resistant glass tube 11, and includes an interface 14 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com