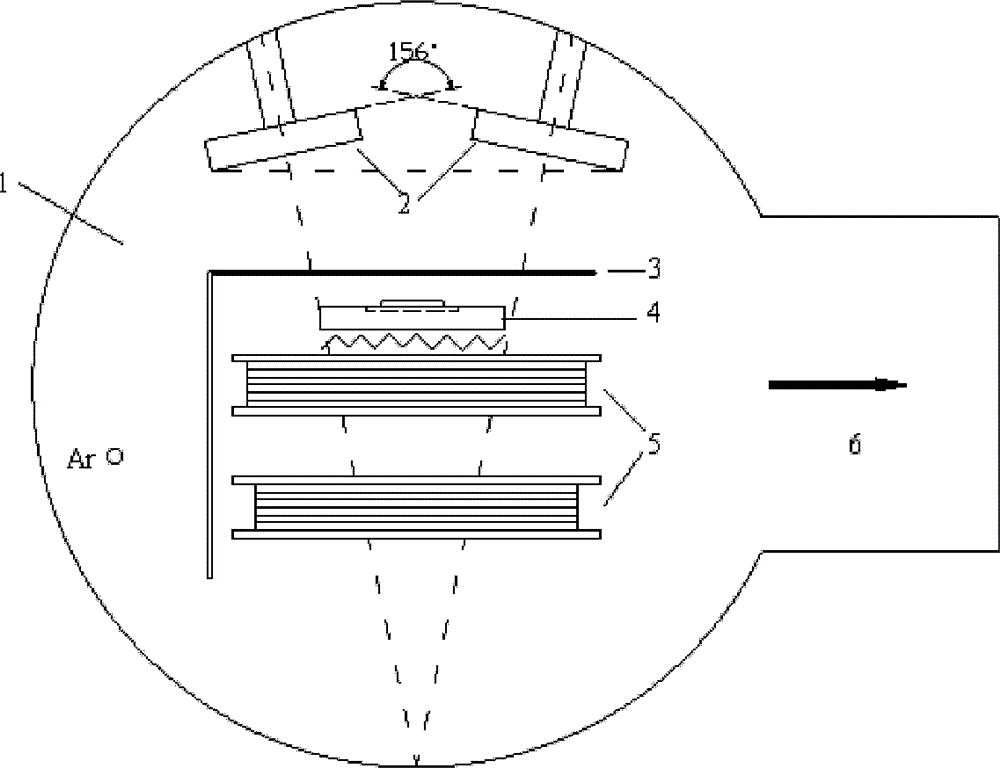

Method for preparing nanometer silicon film through intermediate-frequency magnetron sputtering process, and its special device

A technology of nano-silicon film and magnetron sputtering, which is applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of difficult to obtain nano-silicon film, unfavorable disordered silicon network relaxation, silicon Problems such as grain nucleation and growth difficulties, to achieve good thermal stability, wide-range controllable thin film crystal structure, and improve the effect of uneven heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

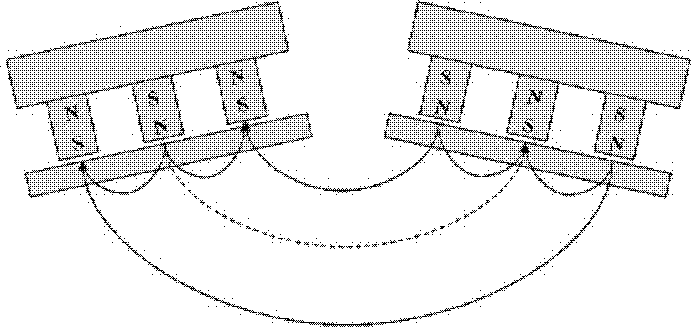

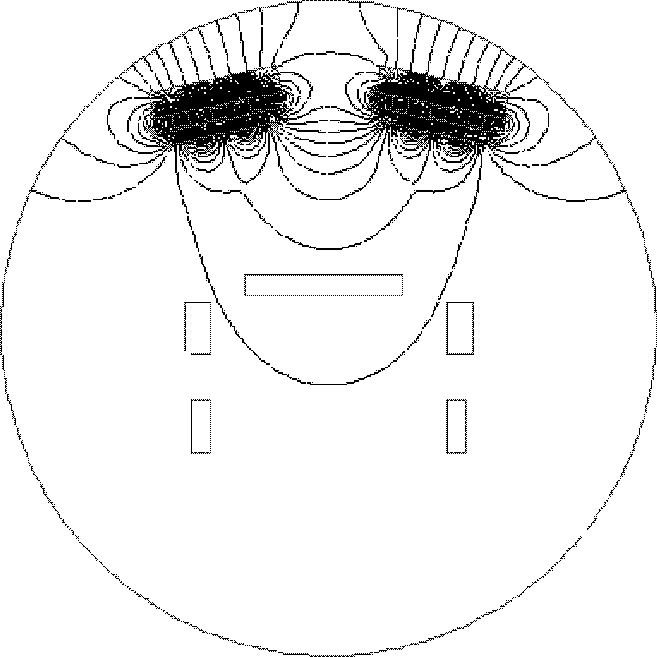

Method used

Image

Examples

Embodiment 1

[0050] Pre-evacuation chamber, background vacuum to 1.5×10 -3 Pa, heat the glass substrate to a temperature of 160°C, and at the same time pass in Ar gas to increase the pressure of the vacuum chamber to 1Pa, keep it warm for 30 minutes for desorption, remove impurities physically adsorbed on the surface of the substrate, and facilitate the combination of the film and the substrate, and Nucleation of silicon thin film; then close the Ar gas and re-evacuate the vacuum chamber to 1.5×10 -3Pa, and heat the substrate again, so that the substrate temperature rises to about 500°C; enter Ar gas, the ventilation volume is about 100sccm, when the vacuum chamber pressure rises to 1Pa, turn on the power supply of the silicon target and adjust the voltage to 760V for pre-sputtering , the sputtering time is 30min, which can effectively eliminate the intrinsic oxide layer on the surface. Then keep the vacuum chamber pressure constant, adjust the target power supply and electromagnetic coil...

Embodiment 2

[0053] Pre-evacuation chamber, background vacuum to 1.6×10 -3 Pa, heat the copper-coated glass substrate to a temperature of 160°C, and at the same time pass in Ar gas to raise the pressure of the vacuum chamber to 1Pa, keep it warm for 30 minutes for desorption, remove impurities physically adsorbed on the surface of the substrate, and facilitate the combination of the film and the substrate , and the nucleation of the silicon film; then the Ar gas was turned off, and the vacuum chamber was re-evacuated to 1.5×10 -3 Pa, and heat the substrate again, so that the substrate temperature rises to about 490°C; enter Ar gas, the ventilation rate is 100sccm, when the vacuum chamber pressure rises to 1Pa, turn on the silicon target power supply, adjust the voltage to 760V for pre-sputtering, The sputtering time is 30min, which can effectively eliminate the intrinsic oxide layer on the surface. Then adjust the vacuum chamber pressure to 0.6Pa, adjust the target power supply and the el...

Embodiment 3

[0057] Pre-evacuation chamber, background vacuum to 1.5×10 -3 Pa, heat the glass substrate to a temperature of 160°C, and at the same time pass in Ar gas to increase the pressure of the vacuum chamber to 1Pa, keep it warm for 30 minutes for desorption, remove impurities physically adsorbed on the surface of the substrate, and facilitate the combination of the film and the substrate, and Nucleation of silicon thin film; then close the Ar gas and re-evacuate the vacuum chamber to 1.5×10 -3 Pa, and heat the substrate again, so that the temperature of the substrate rises to about 540 ° C; enter Ar gas, the gas flow is 80s ccm, when the pressure of the vacuum chamber rises to 0.6 Pa, turn on the power supply of the silicon target and adjust the voltage to 760V for pre-sputtering Sputtering, the sputtering time is 30min, which can effectively eliminate the intrinsic oxide layer on the surface. Then keep the vacuum chamber pressure constant, adjust the target power supply and the el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com