Disinfection cabinet and control method of disinfection cabinet

A technology of disinfection cabinet and main controller, applied in the field of disinfection cabinet, can solve problems such as uneven heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

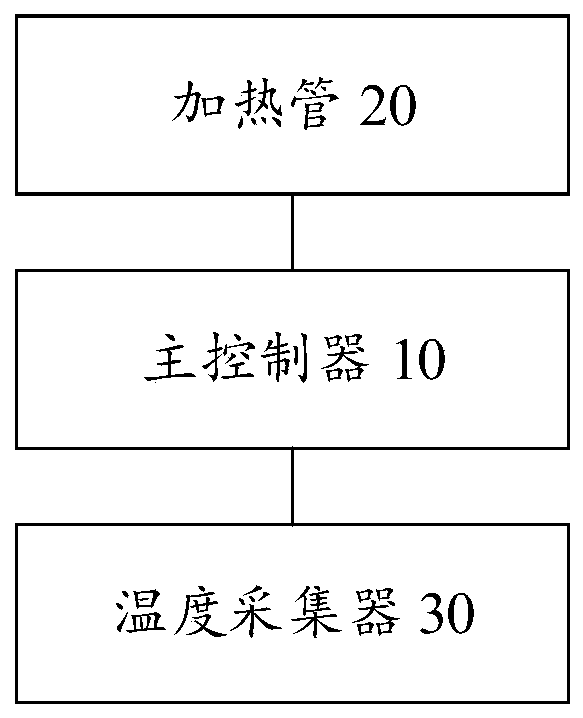

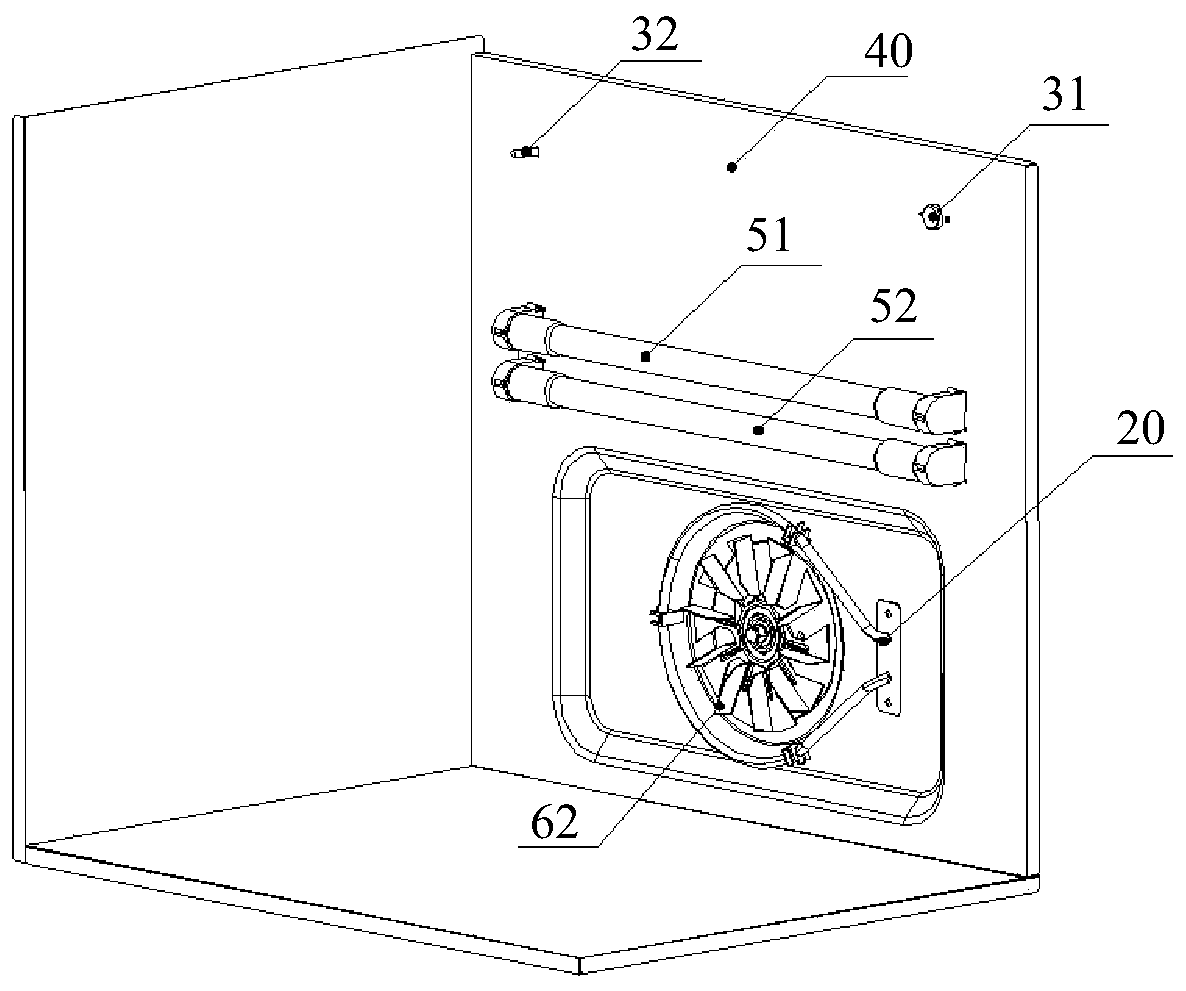

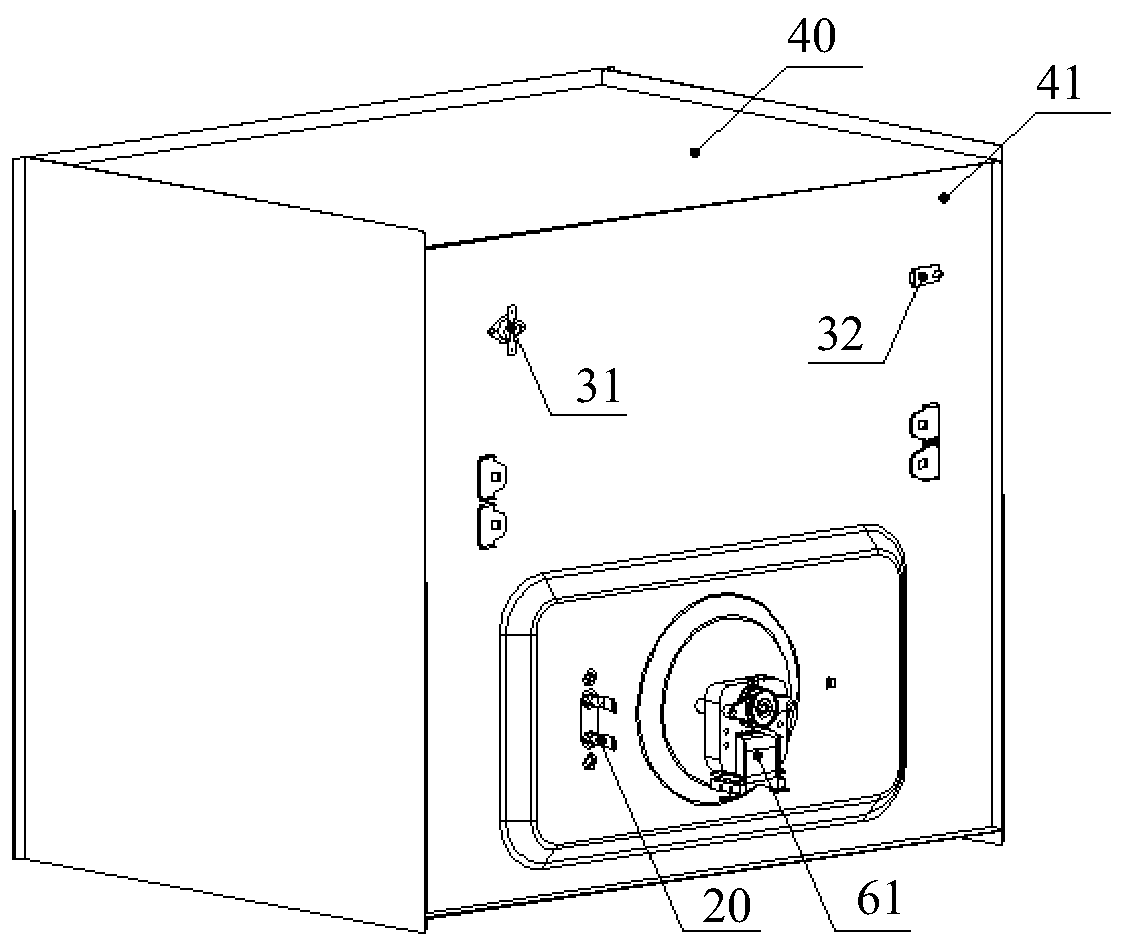

[0031] Refer to as figure 1 As shown in the structural block diagram of the disinfection cabinet, the disinfection cabinet provided in this embodiment includes a cavity 40 , and a heating tube 20 and a temperature collector 30 connected to the main controller 10 are arranged inside the cavity 40 . The main controller 10 is used to receive the mode setting information input by the user, the surface temperature of the tableware and the temperature in the cavity collected by the temperature collector 30, and drive the heating tube 20 to run according to the mode setting information, the surface temperature of the tableware and the temperature in the cavity, wherein , the mode setting information may include a set duration and a set temperature.

[0032] In some possible implementations, an operation panel 70 connected to the main controller 10 may be provided. The operation panel 70 may be understood as an operable device with a touch screen, buttons and / or a voice recognizer. Wh...

Embodiment 2

[0041] Based on the disinfection cabinet provided in the first embodiment above, this embodiment provides a control method applied to the above disinfection cabinet, refer to Figure 5 The flow chart of the control method of the shown disinfection cabinet, the method includes:

[0042] Step S502, receiving mode setting information input by the user, wherein the mode setting information includes setting duration and setting temperature. Specifically, when the disinfection cabinet is started, the user can select the set duration and temperature of the heating through the operation panel, and the above-mentioned mode setting information can be read by the main controller.

[0043] Step S504, based on the mode setting information, the surface temperature of the tableware and the temperature in the cavity are collected by the temperature collector according to a preset collection interval. In a possible specific implementation manner, the surface temperature of the tableware can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com