Vacuum plating cathode target using foam metal for enhancing cooling effect

A metal foam and cathode target technology, which is applied in the field of vacuum plating cathode target, can solve the problems of low heat transfer efficiency between the target material and the back plate, limited increased area, and reduced heat transfer efficiency, so as to improve uneven heating, Effect of preventing local overheating and improving cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

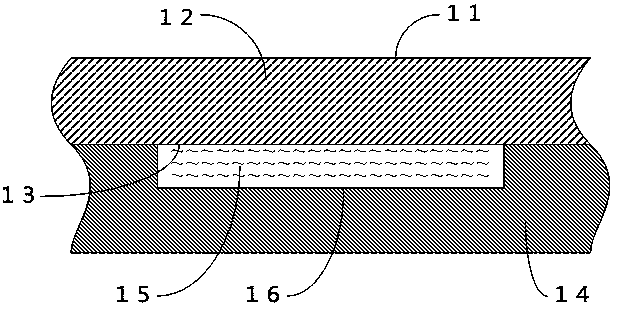

[0032] This embodiment shows a vacuum plating cathode target that uses metal foam to enhance cooling, such as Figure 4 As shown, it includes a yoke 41, a magnet 42, a target 45, a back plate 43, a graphite sheet 44, a copper foam 47, and a coolant flow channel 46, wherein the back plate 43 is made of a copper plate with a thickness of 0.1 mm. A graphite sheet 44 with a thickness of 0.02 mm is arranged between the target 45 and the back plate 43, and a copper foam 47 with an average hole diameter of 0.1 mm is welded on the other side of the back plate 43, and the copper foam 47 is processed to be compatible with the cooling liquid After the size of the flow channel 46 matches, it is filled inside the coolant flow channel 46 . The back plate 43 and the copper foam 47 are connected together by high frequency welding. When the cathode target is working, the coolant flows through the coolant flow channel filled with copper foam, and uses the large surface area of the foam coppe...

Embodiment 2

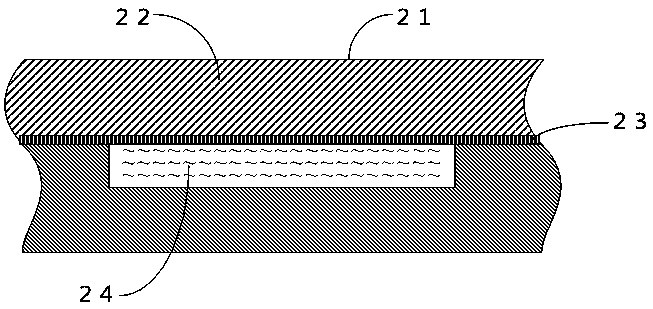

[0034] This embodiment shows a vacuum plating cathode target that uses metal foam to enhance cooling, such as Figure 5 As shown, it includes a yoke 51, a magnet 52, a target 56, a back plate 54, a separator 53, a graphite sheet 55, an aluminum foam 58, and a cooling liquid flow channel 57, wherein the back plate 54 is made of a copper plate with a thickness of 1 mm. A layer of graphite sheet 55 with a thickness of 0.1 mm is arranged between the target material 56 and the back plate 54 . A copper-plated aluminum foam 58 is welded on the other side of the back plate 54, and its average hole diameter is 2 mm. The aluminum foam 58 is processed into a size matching the cooling liquid flow channel 57 and then filled inside the cooling liquid flow channel 57 . The back plate 54 and the aluminum foam 58 are connected together by brazing, and the solder used for brazing is Sn—Bi alloy solder with a melting point of 160° C. When the cathode target is working, the coolant flows throug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com