Toilet seat and preparation method

A technology for seat rings and toilets, applied in the field of toilets, can solve the problems of poor heating effect, waste of energy, heat loss, etc., and achieve the effect of strengthening heat conduction capacity, improving heat conduction capacity, and reducing heat shrinkage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

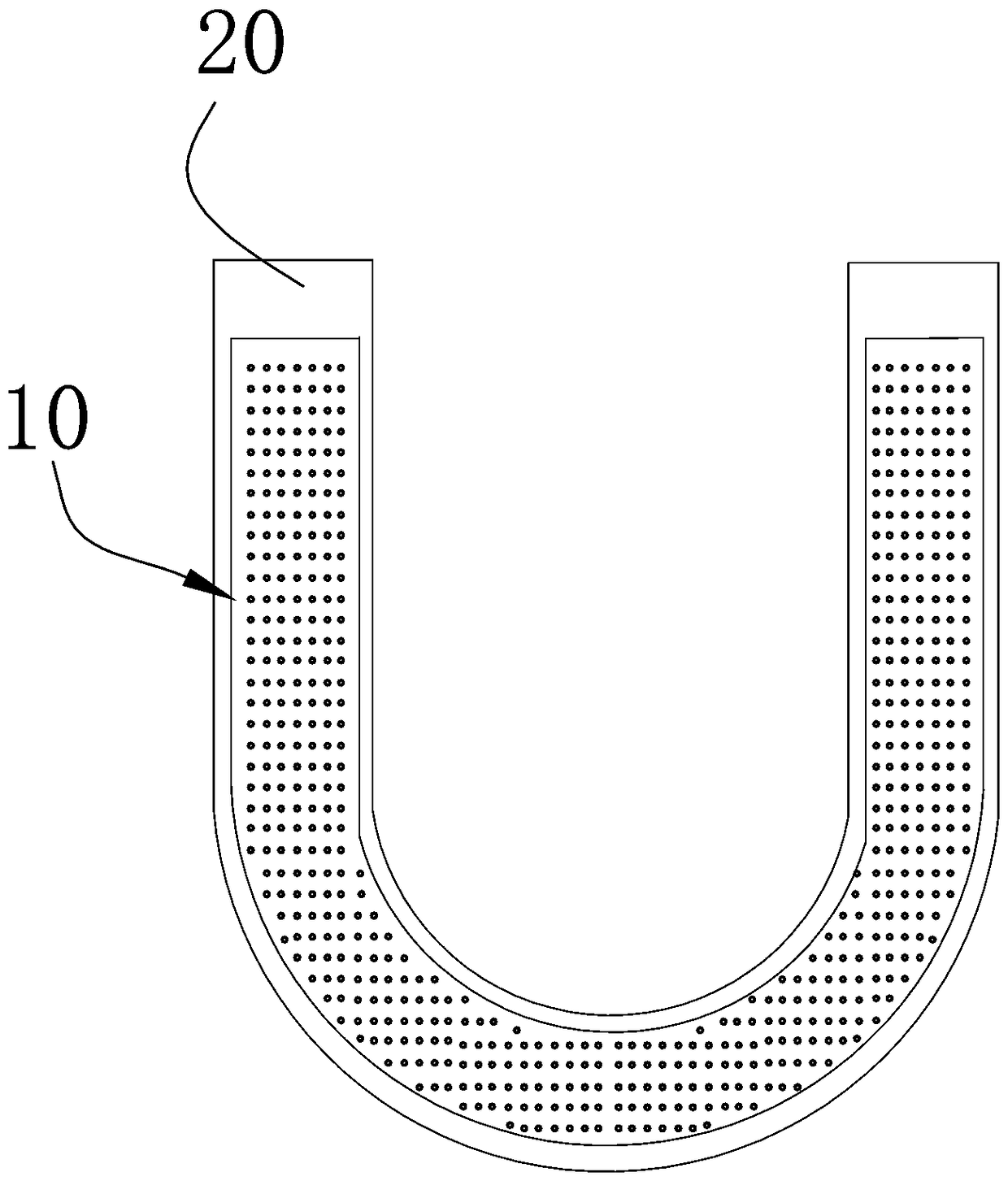

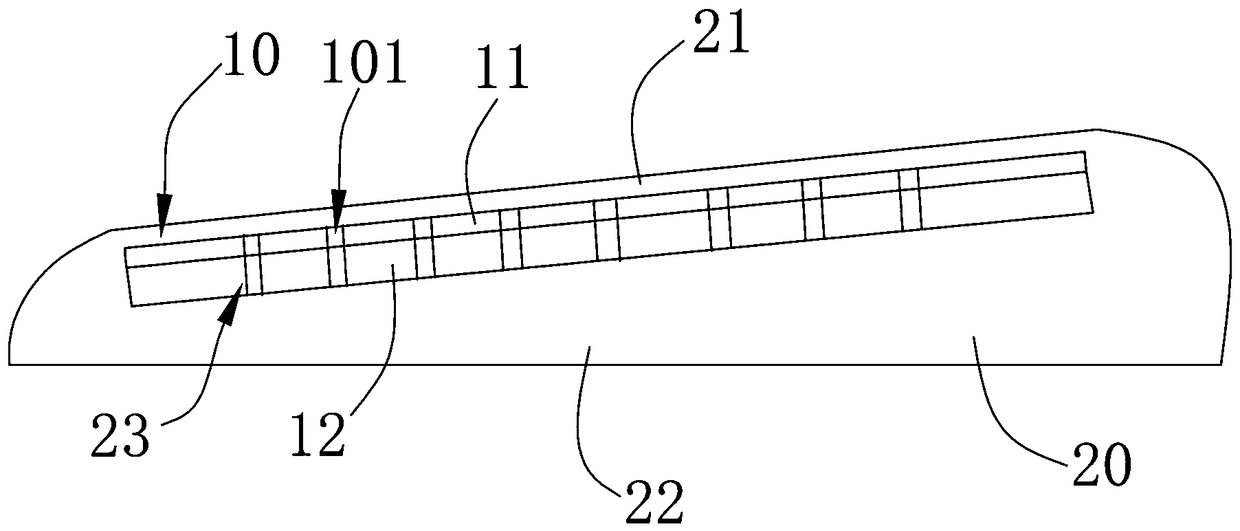

[0041] like figure 1 and 2 As shown, a toilet seat includes a heating unit 10 and a covering body 20 covering the heating unit 10, and the covering body 20 covers the heating unit 10 through a casting process. Preferably, the casting process is a vacuum casting process.

[0042] The heating unit 10 is punched to form a hole structure, and the hole structure includes a plurality of inner holes. In this embodiment, the inner hole is a through hole, that is, the hole structure includes a plurality of through holes 101 , and the covering body 20 covers the heating unit 10 and fills each of the through holes 101 .

[0043] Specifically, the heating unit 10 includes a heating layer 11 and a reinforcement layer 12 stacked in layers, and each of the through holes 101 passes through the heating layer 11 and the reinforcement layer 12 in sequence.

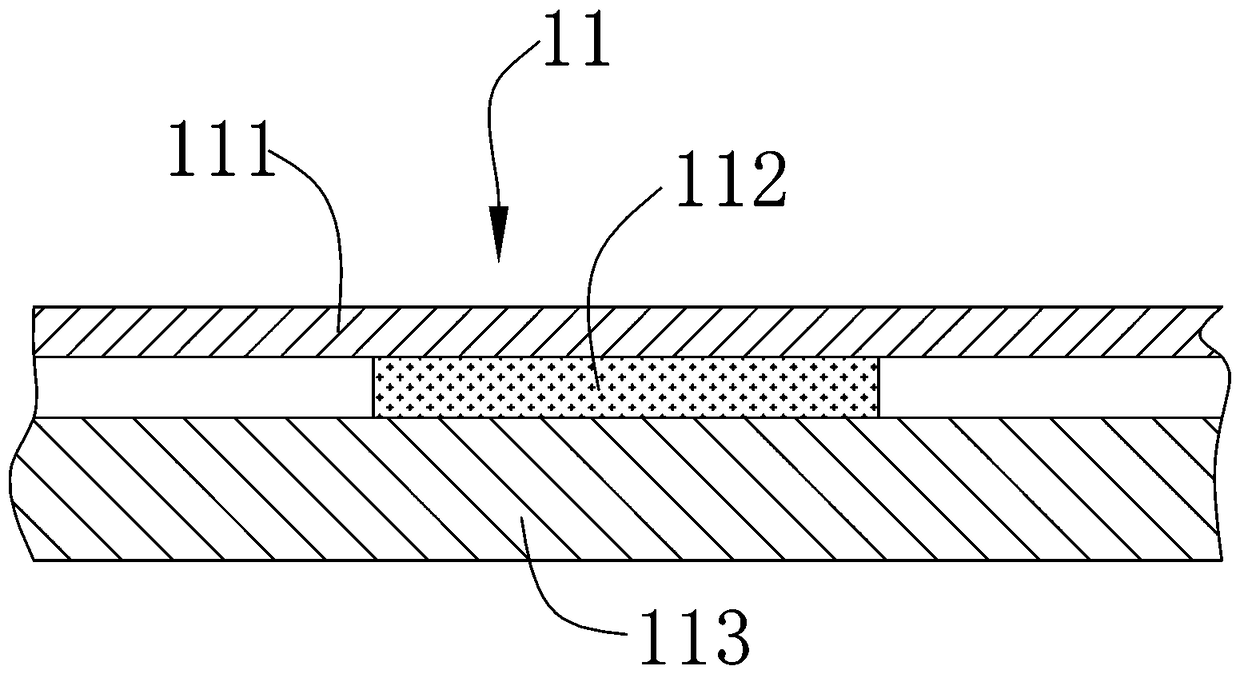

[0044] In this example, if image 3 As shown, the heating layer 11 includes a heat conduction layer 111 , a heat generation layer 112 a...

Embodiment 2

[0071] The preparation method of the toilet seat that embodiment two provides is used for preparing such as figure 2 , Figure 4 or Figure 5 The toilet seat shown. Specifically, such as Image 6 Shown, the preparation method of described toilet seat comprises the steps:

[0072] 1. Mix the raw materials of the covering body evenly to form a pouring liquid;

[0073] 2. Prepare the heating unit 10 with a pore structure;

[0074] 3. Coat the lower surface of the heating unit 10 with corresponding adhesive and fix it on the core-pulling structure 110 of the seat casting mold 100;

[0075] 4. Pouring the liquid casting solution into the casting mold 100 by using a casting process, pulling out the core-pulling structure 110 after being semi-cured and injecting the liquid casting solution into the core-pulling cavity;

[0076] 5. Curing and molding the poured product, and trimming, inspection and packaging of the formed toilet seat.

[0077] It should be noted that in step 1...

Embodiment 3

[0086] The preparation method of the toilet seat provided in embodiment three is used to prepare such as figure 2 , Figure 4 or Figure 5 The toilet seat shown.

[0087] Specifically, as Figure 7 Shown, the preparation method of described toilet seat comprises the steps:

[0088] 1. Mix the raw materials of the covering body evenly to form a liquid pouring solution;

[0089] 2. Prepare the heating unit 10 with a pore structure;

[0090] 3. Prepare the support structure 210 by vacuum casting process, injection molding process or molding process;

[0091] 4. Place the support structure 210 in the seat casting mold 200, and fix the heating unit 10 to the support structure 210;

[0092] 5. The liquid casting solution is poured into the casting mold 200 by a casting process, and solidified and formed, and trimmed, inspected and packaged for the formed toilet seat.

[0093] It should be noted that in step 1, the raw materials of the cladding body are mixed in a low vacuum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com