Semiconductor substrate heat treatment device

A heat treatment device, semiconductor technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to elaborate the spirit of the present invention in detail and help those skilled in the art to practically and comprehensively understand the complete technical solution of the present invention, the following will be described in conjunction with examples and accompanying drawings:

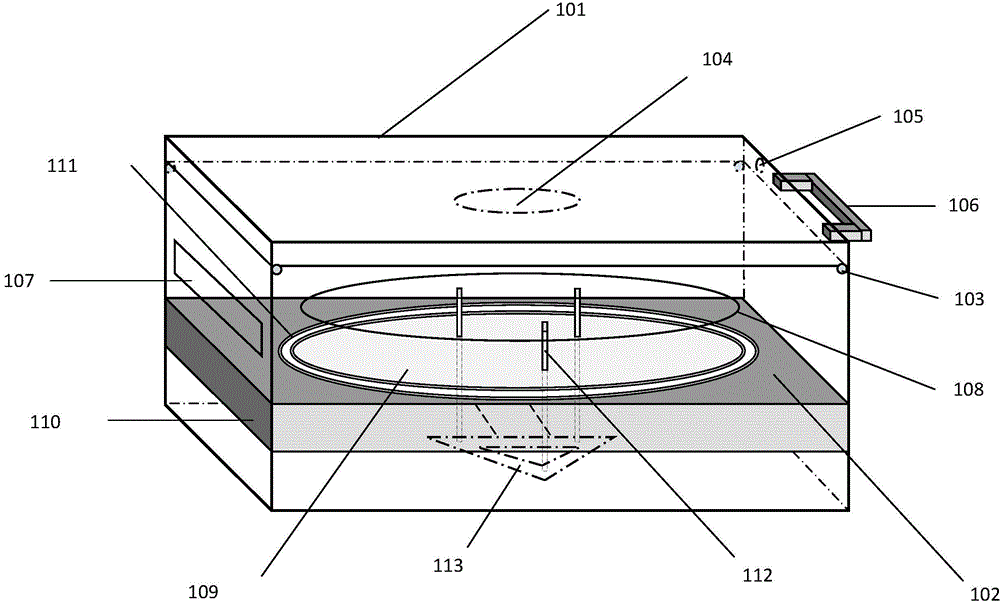

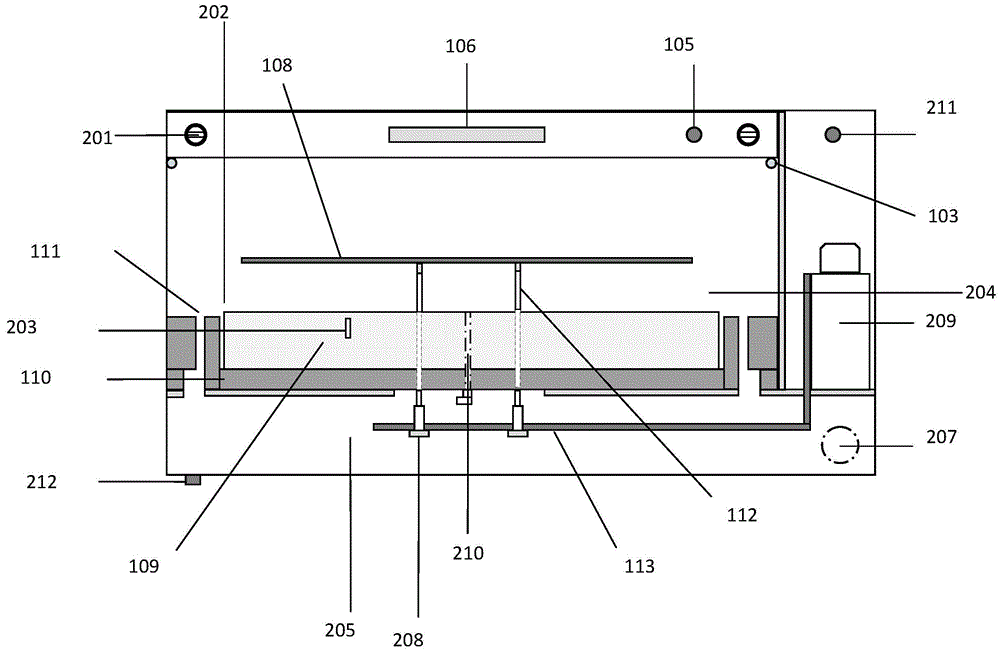

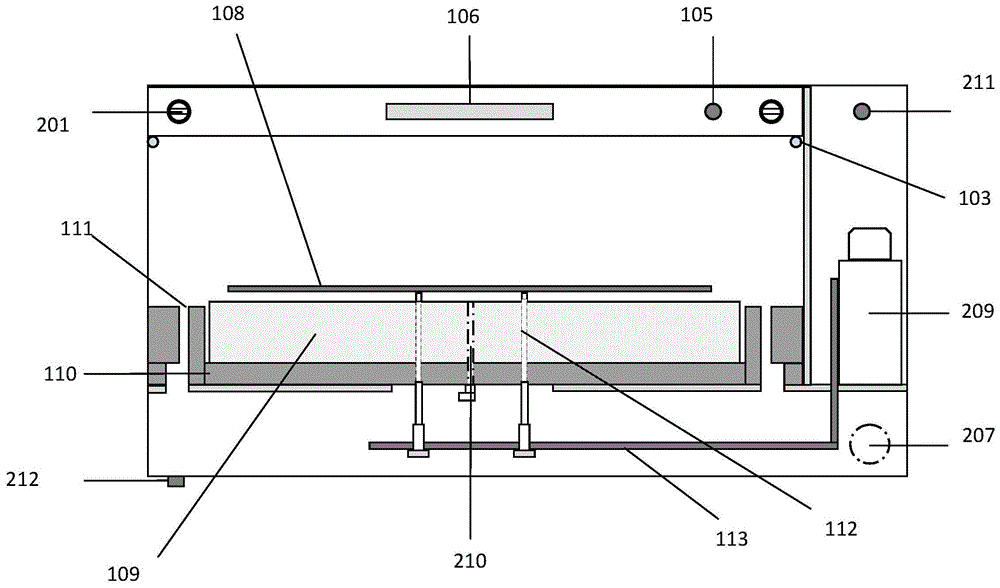

[0039] attached Figure 1-4 Various structural features of specific embodiments of the heat treatment device of the present invention are shown.

[0040] Figure 1-3 The overall display of the wafer heat treatment device of the present invention is carried out. The heat treatment apparatus includes exhaust means and a heating chamber 102 . The exhaust device includes a cuboid exhaust chamber 101 supported by two parallel slide rails 103 and placed above the heating chamber 102 . The two sliding rails 103 are respectively located on two edges below the cuboid exhaust chamber 101 , so that the exhaust chamber 101 can slide along the sliding rails 103 . Further, a circular exhau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com