Method for producing low-hydroxyl value high-temperature sulfuration silicon rubber raw rubber

A technology of raw silicone rubber and high-temperature vulcanization, applied in the field of silicone rubber production, can solve the problems of decreased dispersion of silica, short storage time of mixed rubber, and decreased plasticity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

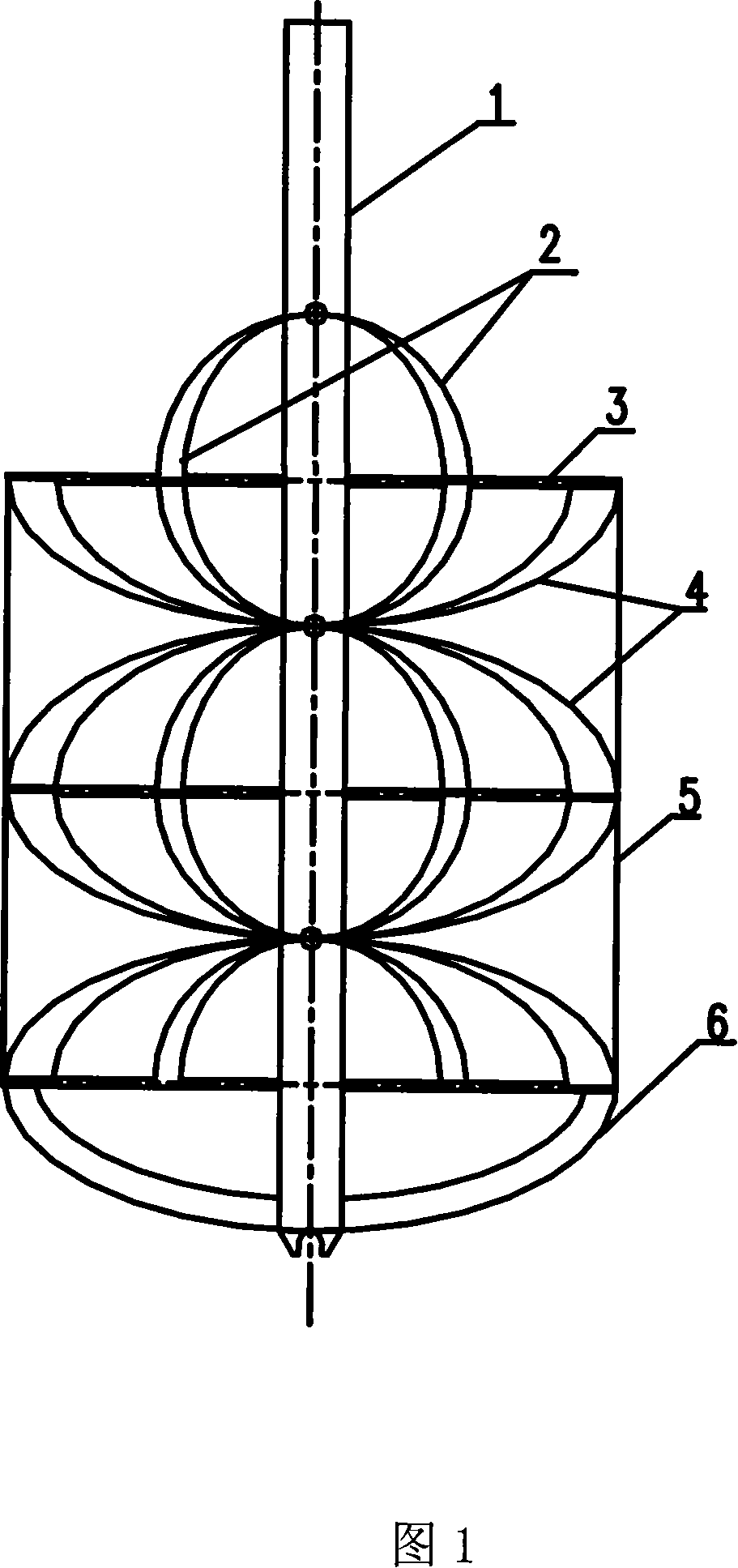

[0012] Press 1000kg of D4 into the dehydration kettle, depressurize, blow nitrogen, 50-60℃, dehydration for 4h, add 0.20kg of tetramethyltetravinylcyclotetrasiloxane, 2.80kg of tetramethylammonium hydroxide silicon alkoxide, 1.10kg of hexamethyldisiloxane, dehydrated below 60℃ for 40min. The dehydrated material is pressed into the polymerization kettle through the metering tank, and the temperature is raised to 100-110°C, and the double-pair spiral ribbon scraping wall stirrer is used to stir and react for 4 hours. After the polymerization is completed, the temperature of the reactor is increased to 160°C, and the vacuum pump is turned on for 2 hours. Turn off the vacuum pump, lower the temperature to below 120°C, add 300 g of hexamethyldisilazane, stir and maintain for 1 hour. The temperature of the reaction kettle was increased to 160-180°C, and the vacuum pump was turned on at the same time, stirring, and maintaining for 3 hours. Finally, cooling water is passed through the wal...

Embodiment 2

[0017] The preparation method is the same as in Example 1, except that the ingredients are changed to: D 4 Change to a mixed ring DMC 500kg (the content of D4 and D5 in the mixed ring DMC is not less than 80%, at 25℃, the viscosity is 2.10-3.50mm 2 / s), tetramethyltetravinylcyclotetrasiloxane 50kg, tetramethylammonium hydroxide silicon alkoxide 1.60kg, hexamethyldisiloxane 0.750g. The obtained raw rubber related data are shown in Table 1.

Embodiment 3

[0019] The preparation method is the same as in Example 1, except that the ingredients are changed to: DMC800kg, tetramethyltetravinylcyclotetrasiloxane 3.8kg, tetramethylammonium hydroxide siliconate 2.80kg, tetramethyldivinyldisiloxane 0.70g. The obtained raw rubber related data are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com