cooktop burner

A technology for burners and stoves, which is applied to burners, gas fuel burners, combustion types, etc., can solve the problems of difficulty in secondary air supplementation and large volume of aeration chambers, and achieve the effect of improving combustion efficiency and heating area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

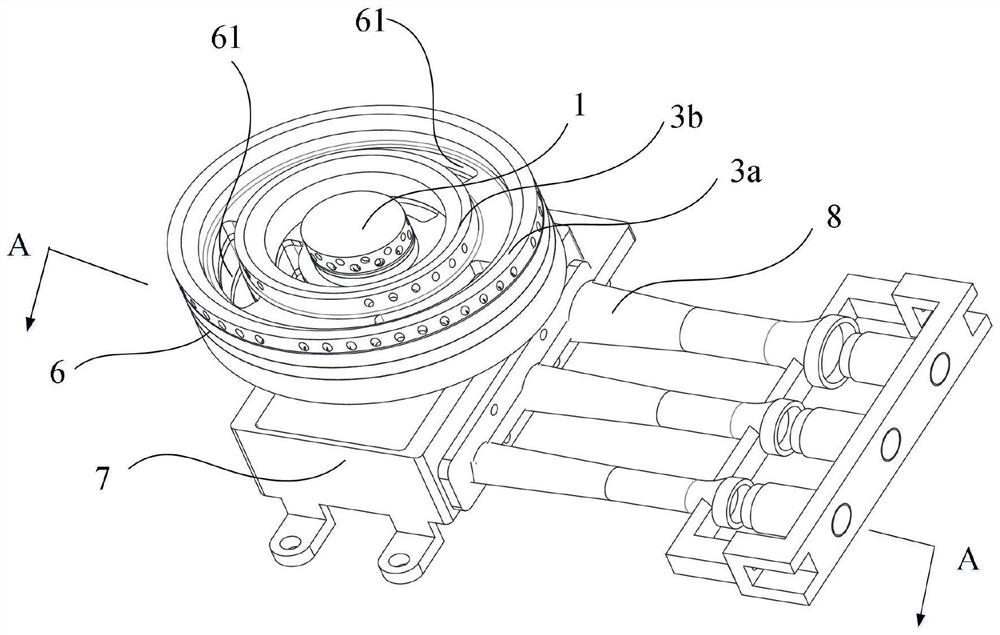

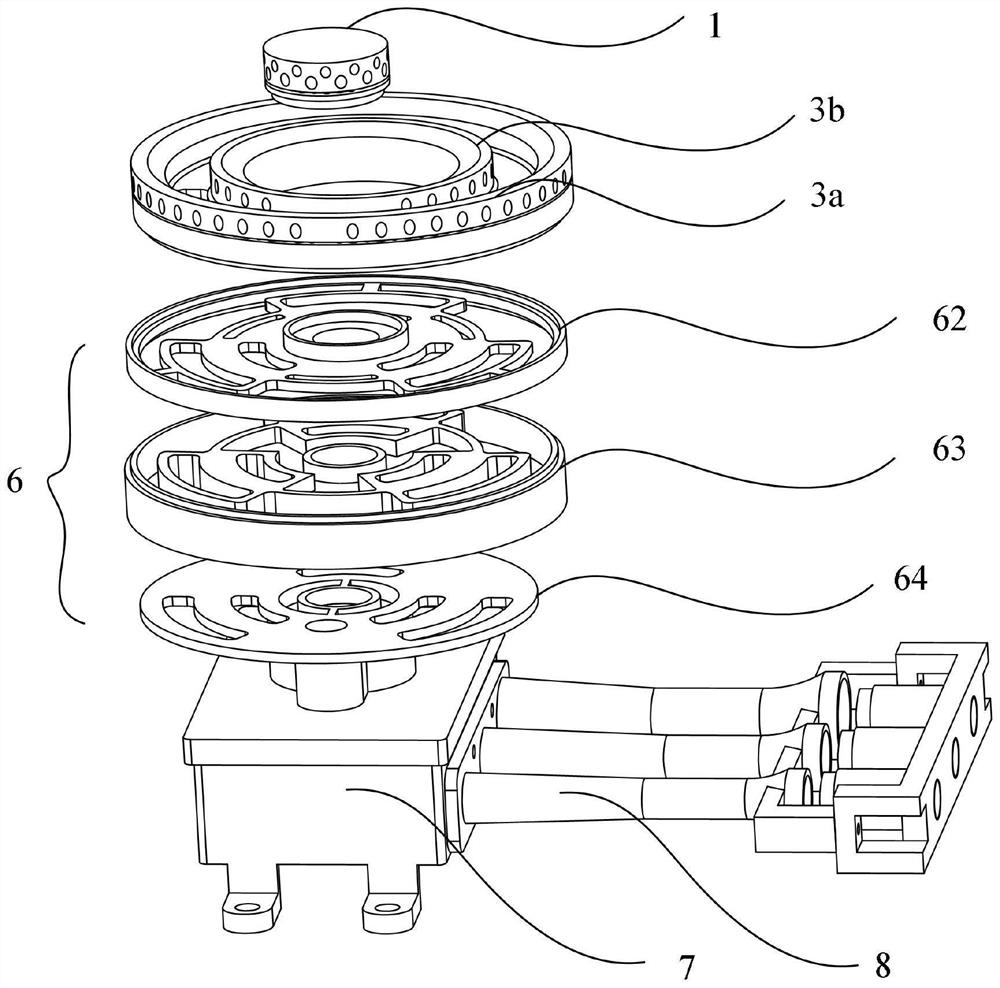

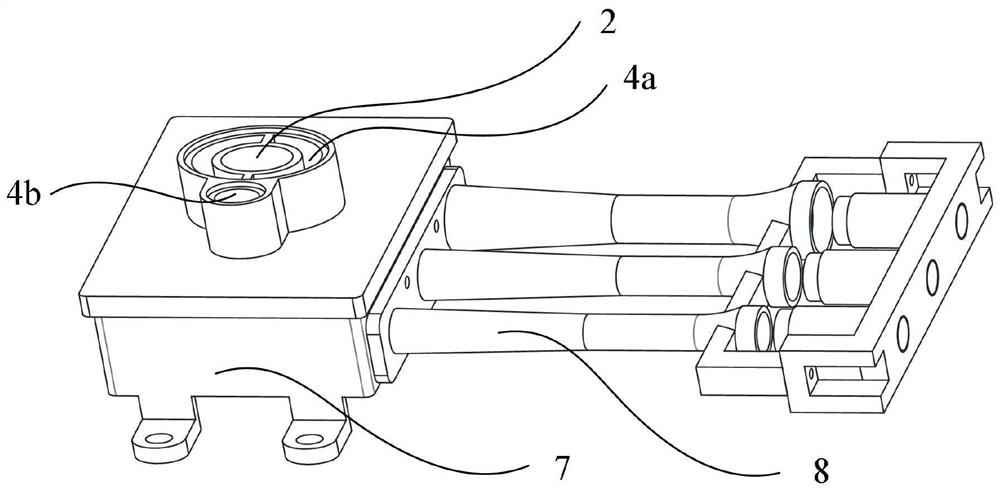

[0052] In the following, the present invention will be more clearly and completely described by way of embodiments in conjunction with the accompanying drawings, but the present invention is not limited to the scope of the described embodiments.

[0053] Such as Figure 1-Figure 5As shown, the present invention discloses a cooker burner, which includes an inner ring fire cover 1 and an inner ring gas channel 2, the inner ring gas channel 2 is vertically arranged in the middle of the cooker burner, and the cooker burner also includes at least two The outer ring fire covers 3a and 3b that are independent of each other, and the outer ring gas passages 4a and 4b corresponding to the number of the outer ring fire covers 3a and 3b, the outlet of the outer ring gas passage 4a is connected to the corresponding outer ring fire cover 3a, and the outer ring The outlet of the gas channel 4b communicates with the corresponding outer ring fire cover 3b. Among them, the outer ring gas chann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com