High-oxygen resistant steaming-resistant polyvinylidene chloride coating film and manufacturing method thereof

A technology of polyvinylidene chloride and vinylidene chloride, which is applied to chemical instruments and methods, devices for coating liquid on surfaces, coatings, etc., and can solve problems such as easy pinholes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

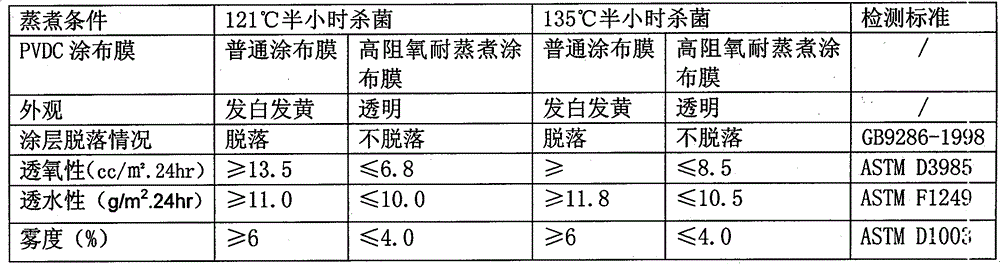

Image

Examples

Embodiment 1

[0032] Substrate: biaxially oriented polyester (BOPET), thickness 12 μm.

[0033] Nano material filler 7.5kg

[0034] Main agent: commercially available main agent 17.5kg

[0035] Curing agent: commercially available curing agent 3.5kg

[0036] Solvent: commercially available solvent 70kg

[0037] Polyvinylidene chloride emulsion: self-made polyvinylidene chloride emulsion 175kg

[0038] Softened water: 300kg

[0039] Slip agent: commercially available palm wax slip agent 3kg

[0040] Anti-blocking agent: 2.5kg of commercially available silicon dioxide anti-blocking agent

[0041] Weigh 175kg of the above-mentioned polyvinylidene chloride blended emulsion and add it to a stainless steel container, while stirring, add 3kg of palm wax slip agent, 7.5kg of nanomaterial filler, 2.5kg of silicon dioxide anti-sticking agent and 300kg of softening agent. water, stir evenly to form a modified retort-resistant polyvinylidene chloride emulsion, which is used in the coating process...

Embodiment 2

[0047] Substrate: biaxially oriented polyester (BOPET), thickness 12 μm.

[0048] Nano material filler 24kg

[0049] Main agent: commercially available main agent 20kg

[0050] Curing agent: commercially available curing agent 4kg

[0051] Solvent: commercially available solvent 80kg

[0052] Polyvinylidene chloride emulsion: self-made polyvinylidene chloride emulsion 200kg

[0053] Softened water: 152kg

[0054] Slip agent: commercially available palm wax slip agent 4kg

[0055] Anti-blocking agent: commercially available silica anti-blocking agent 20kg

[0056] Take by weighing 200kg above-mentioned polyvinylidene chloride blended emulsion that makes and add in the stainless steel container, add 4kg palm wax slippery agent, 24kg nanometer material filler, 20kg silicon dioxide antisticking agent and 152kg demineralized water successively while stirring, After stirring evenly, the modified retort-resistant polyvinylidene chloride emulsion is ready to be used in the coati...

Embodiment 3

[0062] Substrate: biaxially oriented polyester (BOPET), thickness 12 μm.

[0063] Nano material filler 5kg

[0064] Main agent: commercially available main agent 8.8kg

[0065] Curing agent: commercially available curing agent 1.76kg

[0066] Solvent: commercially available solvent 35.2kg

[0067] Polyvinylidene chloride emulsion: self-made polyvinylidene chloride emulsion 88kg

[0068] Demineralized water: 5.9kg

[0069] Slip agent: commercially available palm wax slip agent 1kg

[0070] Anti-blocking agent: 0.1kg of commercially available silicon dioxide anti-blocking agent

[0071] Weigh 88kg of the above-mentioned polyvinylidene chloride blended emulsion and add it to a stainless steel container, while stirring, add 1kg of palm wax slip agent, 5kg of nanomaterial filler, 0.1kg of silicon dioxide anti-sticking agent and 5.9kg of softening agent successively. water, stir evenly to form a modified retort-resistant polyvinylidene chloride emulsion, which is used in the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com