Method for producing white light luminous diode

A technology of light emitting diodes and a manufacturing method, which is applied to electrical components, circuits, semiconductor devices, etc., can solve problems such as inability to use, inconvenience, and edge defects of the fluorescent layer 23, and achieve the effect of increasing the value of the manufacturing method and making it widely available.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation methods, methods, steps, Features and their functions are described in detail below.

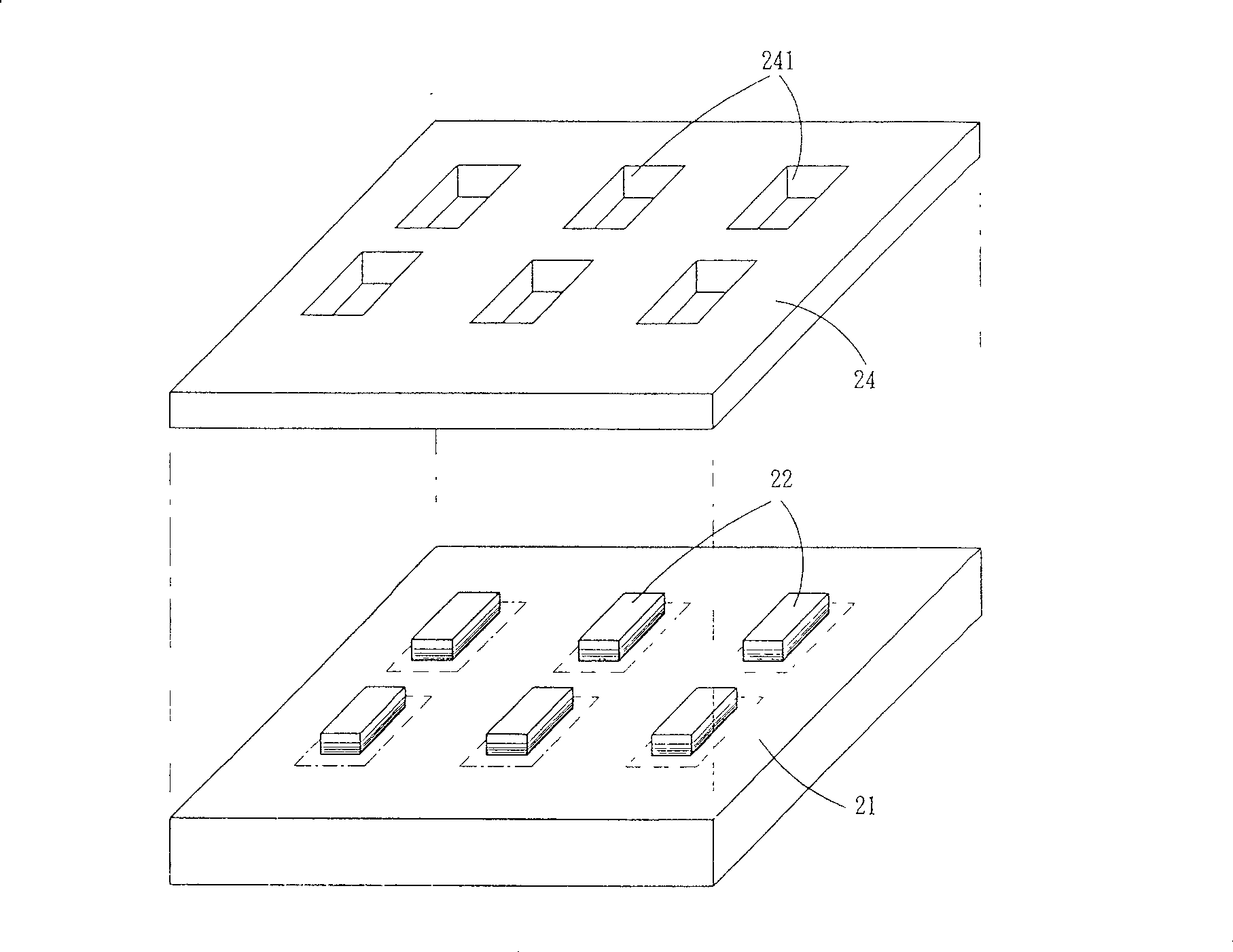

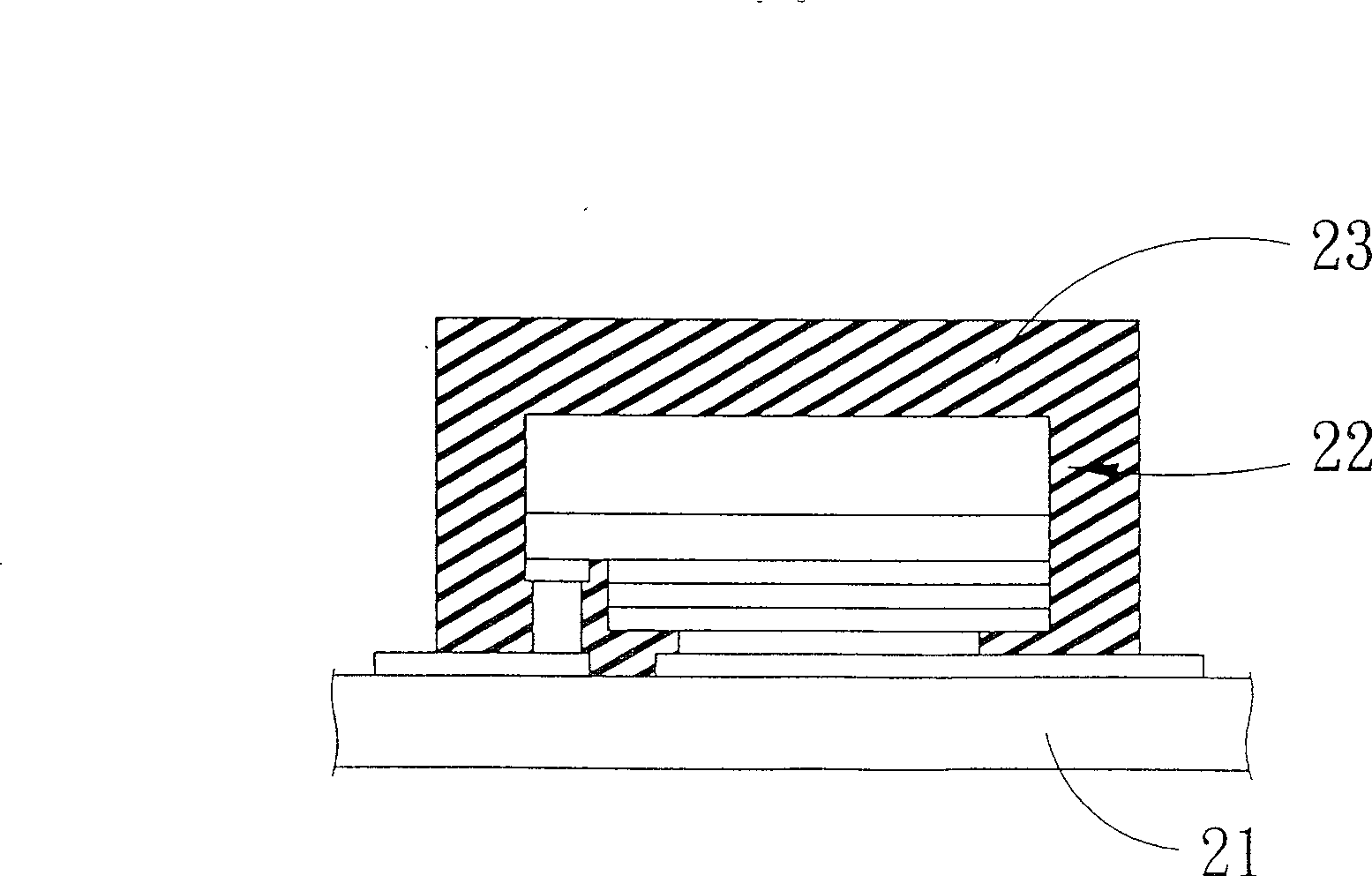

[0046] see Figure 4 and Figure 5 As shown, the manufacturing method of the white light emitting diode of the preferred embodiment of the present invention mainly includes the following steps:

[0047] First, step 41 first provides the base 31;

[0048] Then, in step 42 , the LED die (hereinafter referred to as die) 32 is bonded on the base 31 . The way of bonding is to first place the silver glue as an adhesive material on the base 31, then set the crystal grains 32 on the silver glue, and finally make the silver glue heat and solidify. The conventional eutectic alloy (Eutectic) bonding can also be used for the above-mentioned grain bonding method.

[0049] Next, see Figure 4 , Image 6 and Figure 7 As shown, ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com