System for producing modified coal tar pitch and preparation method thereof

A technology for modified asphalt and production system, which is applied in the processing of tar asphalt/petroleum asphalt/natural asphalt and the petroleum industry, etc. It can solve the problems of affecting the service life of equipment and heat transfer effect, increasing energy and power consumption, and long heating time of materials and other issues to achieve the effect of saving power consumption, reducing power and energy consumption, and stabilizing quality indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

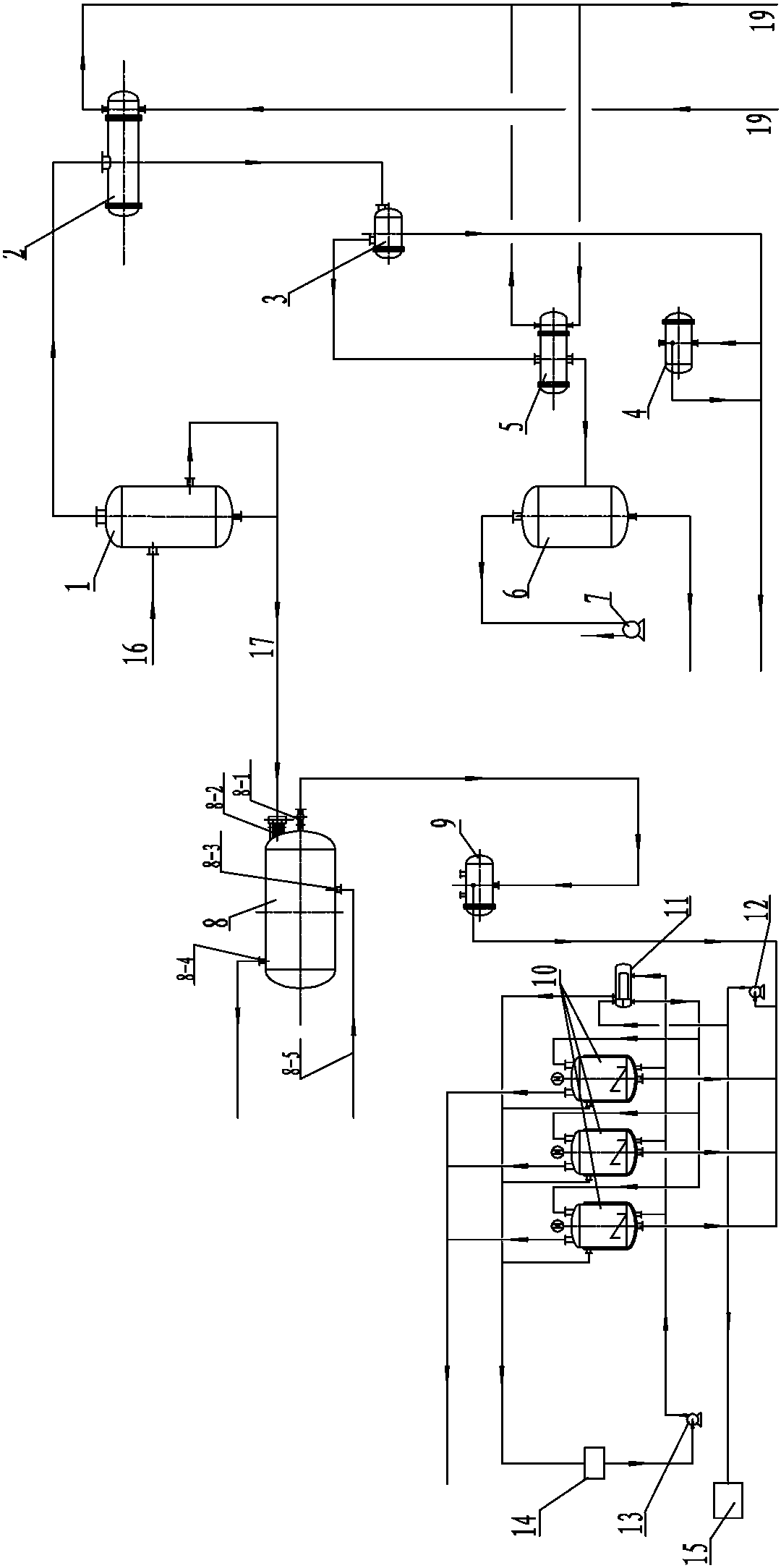

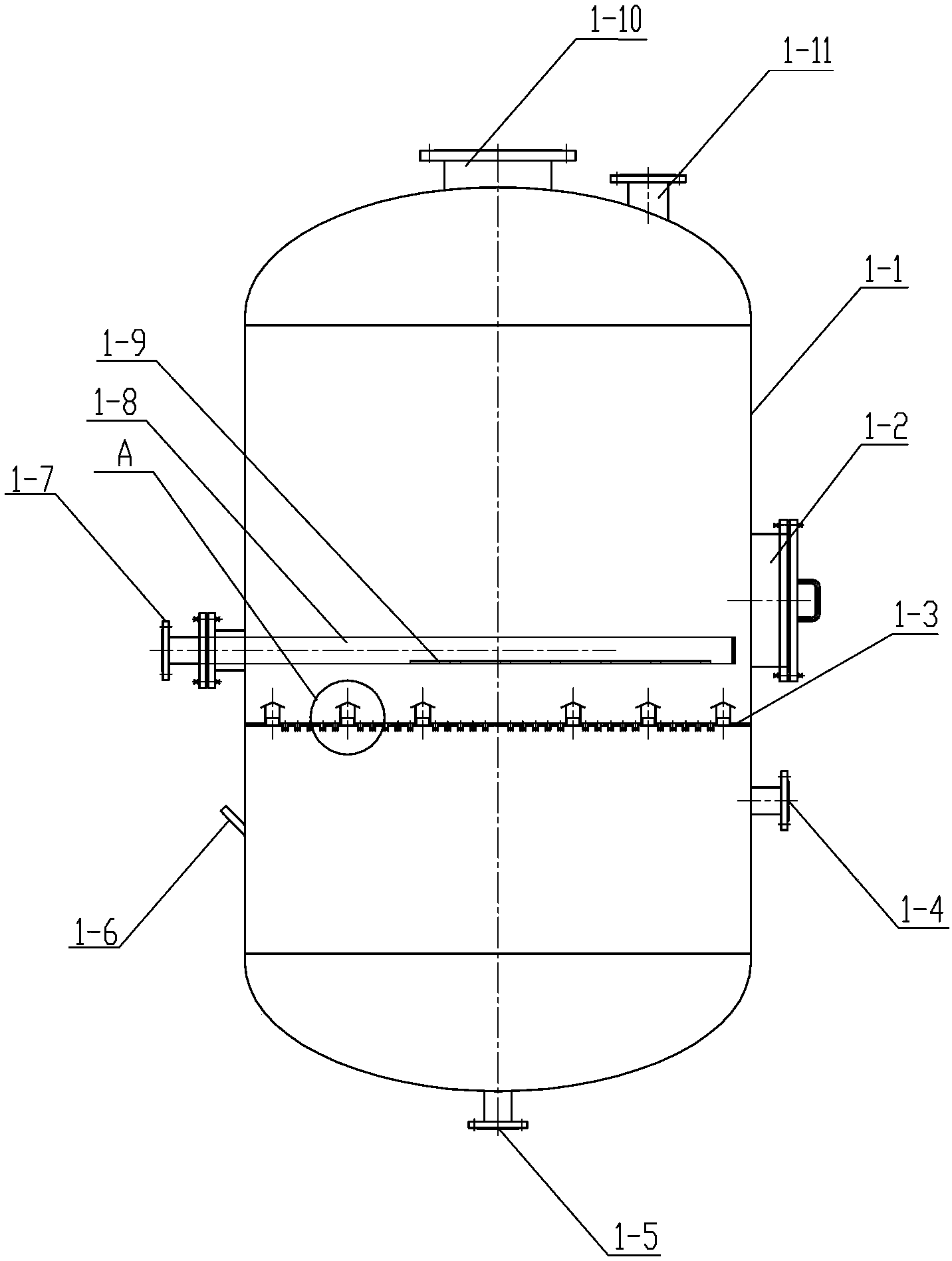

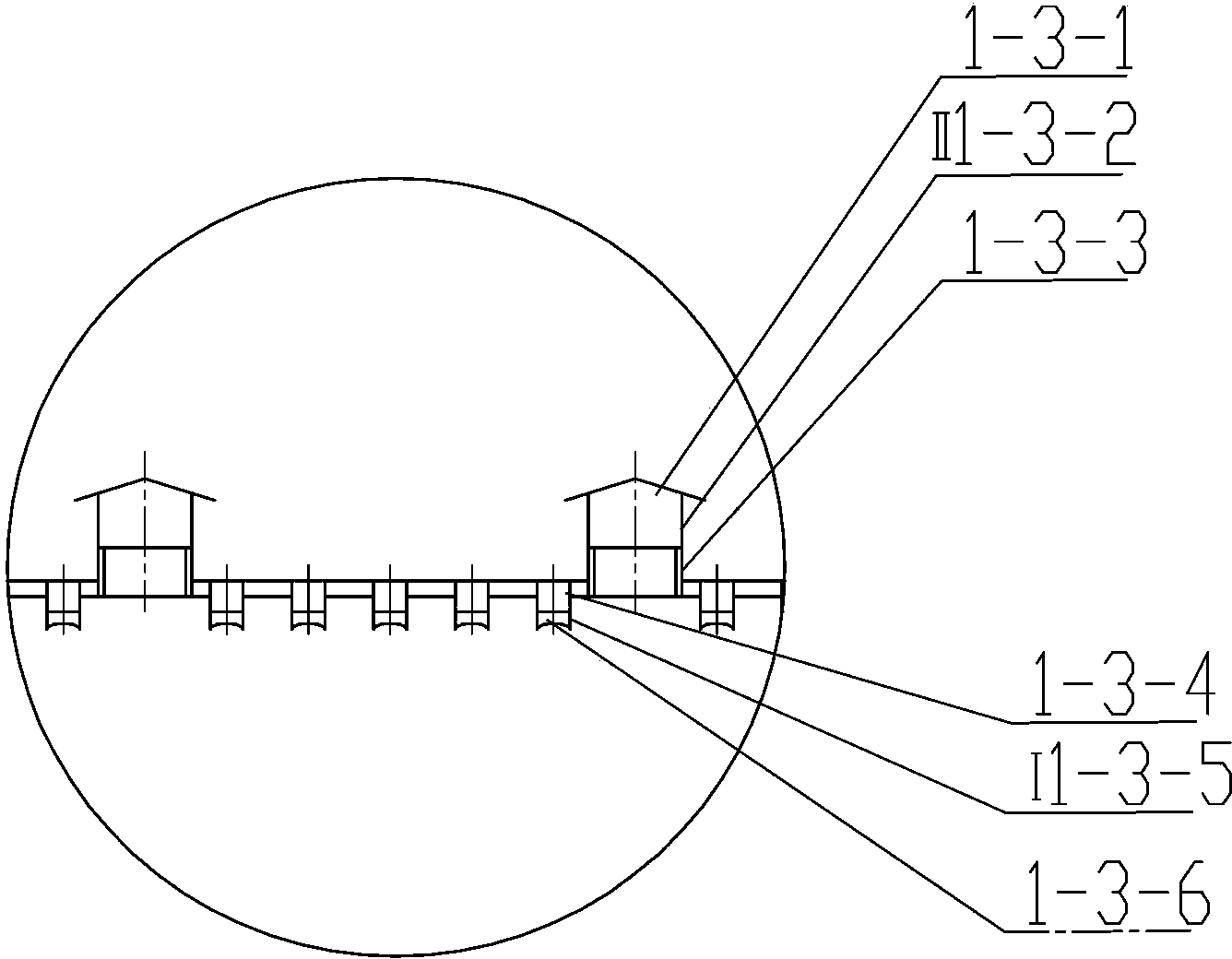

[0062] The preparation method of a modified asphalt of the present invention is characterized in that: the medium temperature asphalt from the secondary evaporator of the tar processing device is sent to the modified intermediate asphalt processing equipment with a flash oil gas processing device through a pipeline, and the processed The flash oil and gas after flash evaporation in the vacuum flash evaporator is sent to the heavy oil treatment equipment for heavy oil fractionation, separation and condensation recycling, and the modified intermediate asphalt after flash evaporation is sent to the asphalt modification reaction equipment to produce modified asphalt. The specific steps as follows:

[0063] 1) Start the vacuum pump first, and vacuum the vacuum flasher 1 to keep the vacuum degree of the vacuum flasher 1 at -20Kpa~-5Kpa;

[0064] 2) The medium-temperature asphalt from the secondary evaporator with a temperature of 360°C to 370°C flows into the vacuum flash evaporator...

example 1

[0075] The preparation method of a modified asphalt of the present invention is characterized in that: the medium temperature asphalt from the secondary evaporator of the tar processing device is sent to the modified intermediate asphalt processing equipment with a flash oil gas processing device through a pipeline, and the processed The flash oil and gas after flash evaporation in the vacuum flash evaporator is sent to the heavy oil treatment equipment for heavy oil fractionation, separation and condensation recycling, and the modified intermediate asphalt after flash evaporation is sent to the asphalt modification reaction equipment to produce modified asphalt. The specific steps as follows:

[0076] Firstly, start the vacuum pump to evacuate the vacuum flash evaporator 1, so that the vacuum degree of the vacuum flash evaporator 1 is between -10 Kpa and -5 Kpa; the medium-temperature asphalt from the secondary evaporator with a temperature of 360°C and 370°C flows into the va...

example 2

[0079] A kind of preparation method of modified asphalt of the present invention is to send the medium temperature asphalt from the secondary evaporator of the tar processing device into the modified intermediate asphalt processing equipment with the flash oil gas processing device through the pipeline, and the After flashing, the flash oil and gas are sent to the heavy oil treatment equipment for heavy oil fractionation, separation and condensation recycling, and the modified intermediate bitumen after flashing is used as the modified intermediate bitumen on the one hand, and passed through the modified intermediate bitumen conveying pipe Send it to the asphalt modification reaction equipment to produce modified asphalt. On the other hand, as the final product of hard asphalt, it is directly sent to the hard asphalt forming device through the hard asphalt delivery pipeline. The specific steps are as follows:

[0080] First, start the vacuum pump to evacuate the vacuum flash ev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com