Method for measuring shrinkage factor of PDP (Plasma Display Panel) glass

A measurement method and shrinkage rate technology, applied in the direction of thermal expansion coefficient of materials, etc., can solve the problems of large measurement error, bursting of measurement samples, etc., and achieve the effects of accurate and reliable data, uniform thermal shrinkage, and simple and convenient measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

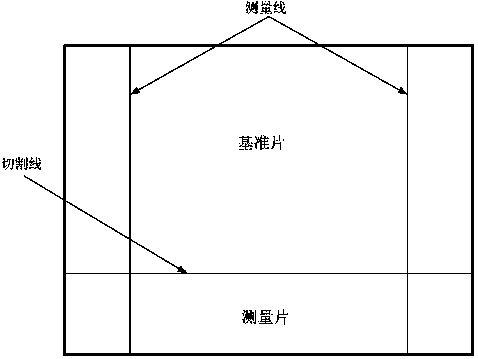

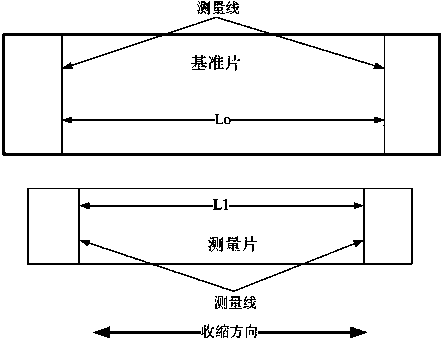

[0024] The specific embodiment of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0025] The assay method of PDP glass shrinkage of the present invention comprises the following steps, step 1. draws measurement line on PDP glass sample, cuts PDP glass sample and is divided into reference sheet and measurement sheet, and cutting line divides measurement line; Step 2. Place the measuring piece in the closed cavity surrounded by two porcelain boats, and the two ends and sides of the measuring piece and the inner wall of the porcelain boat are filled with flexible high-temperature resistant materials; Step 3. The porcelain boat and the measuring piece The whole is heated according to the preset heating curve; step 4. After the heating is completed, anneal and cool the measuring sheet, compare the measuring line displacement of the reference sheet and the measuring sheet, and calculate the shrinkage rate.

[0026] Gla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com