Internal heat rotary kiln coal dry distillation device

A technology of internal heating rotary kiln and heating device, which is applied in the direction of special dry distillation, indirect heating dry distillation, petroleum industry, etc., can solve the problems of gas environmental pollution, uneven heating of coal materials, and lower production efficiency, so as to improve the efficiency of dry distillation, The effect of high calorific value and improved utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing, the present invention will be further described:

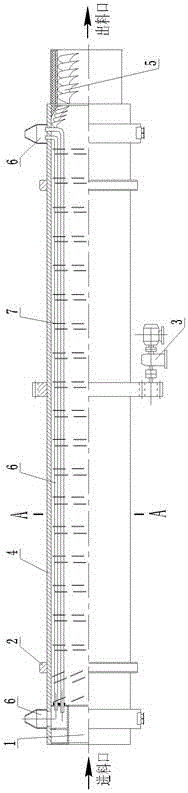

[0019] like figure 1 As shown, an internally heated rotary kiln dry distillation coal device includes a kiln body 4 with a feeding device 1 and a discharging device 5 at both ends; the kiln body 4 adopts a closed structure, and the kiln body 4 is respectively provided There are heating device 6, rotating and stabilizing device 2 and transmission device 3;

[0020] The kiln body is cylindrical, and the kiln body 4 is provided with a pipe rack spiral plate 7 and a heating device 6; The end of device 1 is higher than the end that is provided with discharge device 5;

[0021] Described transmission device 3 comprises large half gear, pinion, speed reducer and motor;

[0022] The rotation stabilizing device 2 includes a rolling ring set on the kiln body, and a supporting wheel device matched with the rolling ring;

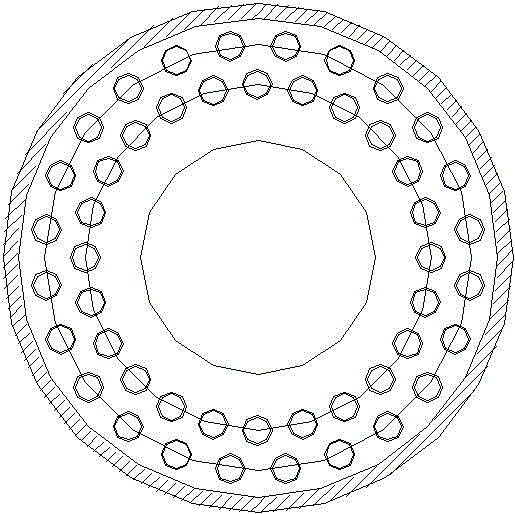

[0023] like figure 2 As shown, the heating device 6 incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com