High-temperature fuel cell system and operating method thereof

A high-temperature fuel cell and operating method technology, applied in the direction of fuel cells, fuel cell additives, fuel cell control, etc., can solve problems such as limited fan performance, accelerated material machinery, and loss of phosphoric acid in batteries to achieve improved uniformity and Consistency, accelerated mechanical aging, and reduced aging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0038] Specific implementation methods include:

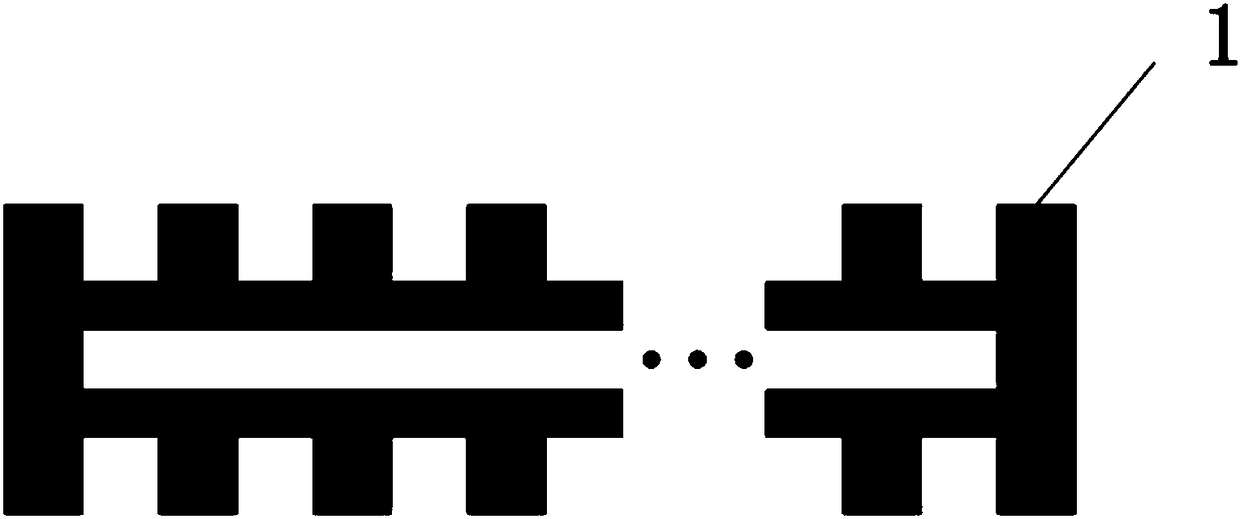

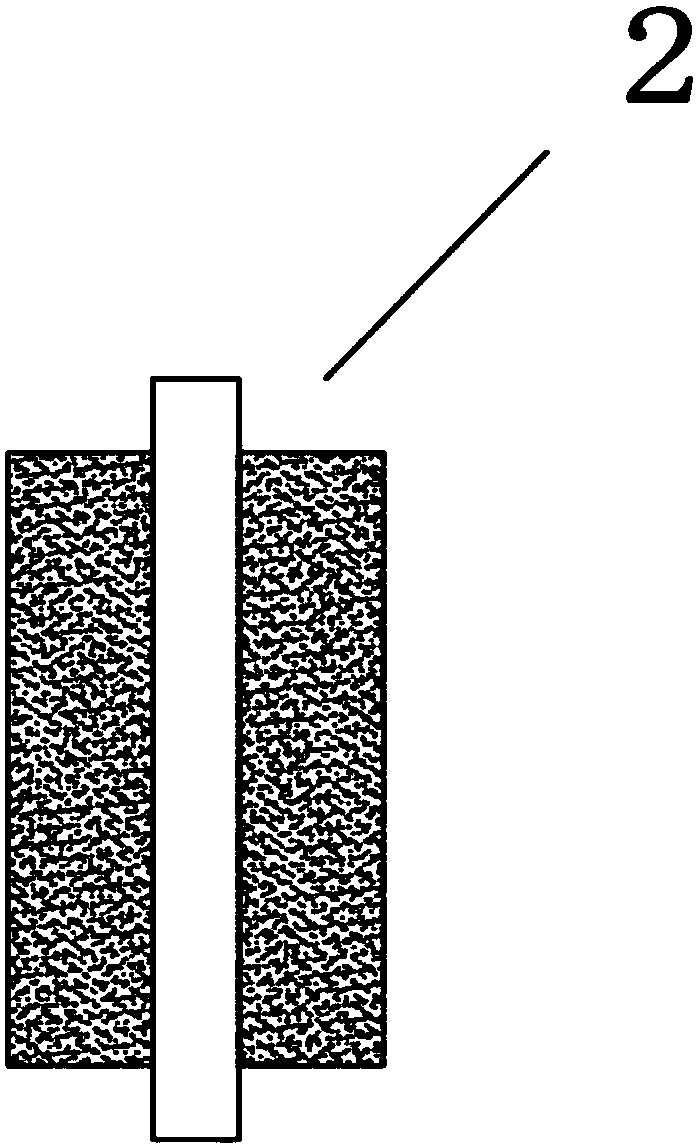

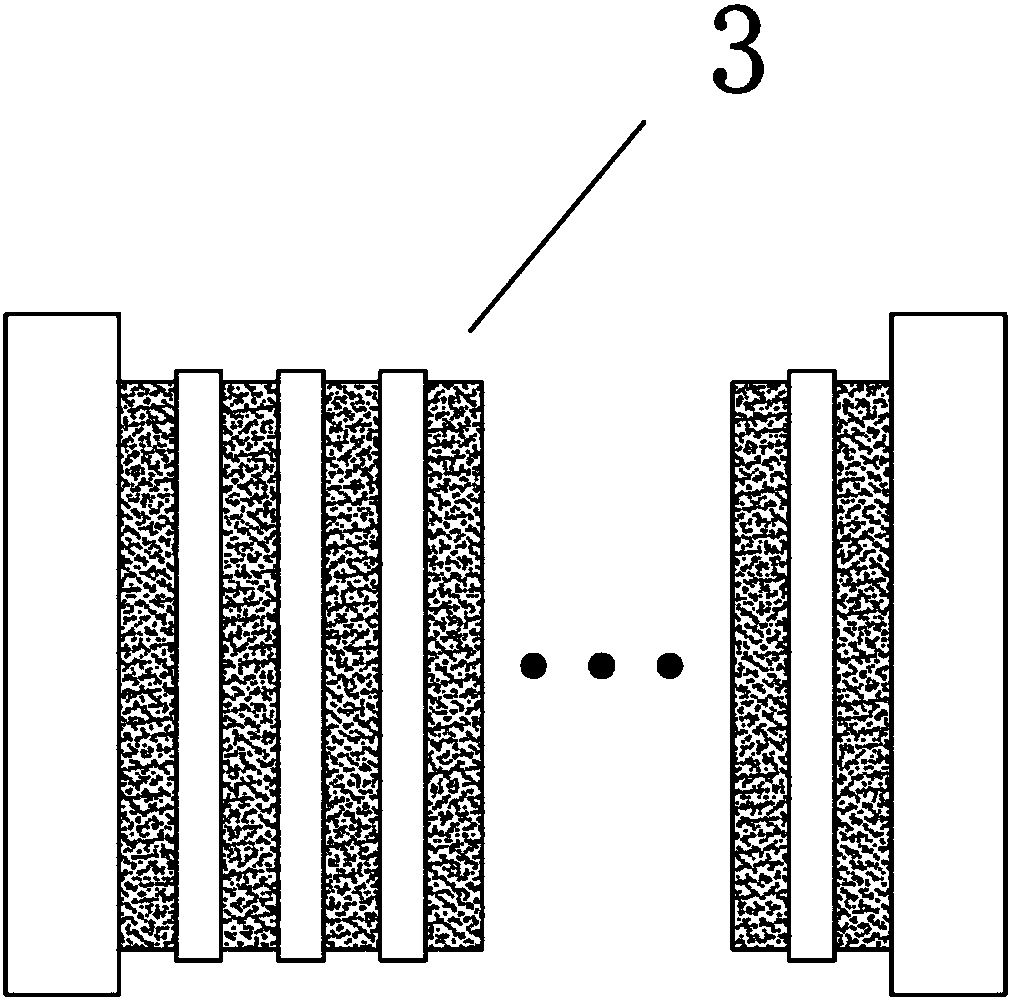

[0039] Bipolar plate 1 is used for fluid distribution and heat transfer oil circulation; membrane electrode assembly 2 is a component unit of fuel cell stack; fuel cell stack 3 is used to convert fuel into electrical energy; heat transfer oil heating device 4 is used for fuel The heat transfer oil flowing in the battery stack system is heated; the heat transfer oil drives the pump to drive the flow of heat transfer oil in the system.

[0040] working principle:

[0041] The high-temperature proton exchange membrane fuel cell uses PBI or TBS membrane, and its proton transmission does not depend on the effect of water, so it can be used at a relatively high temperature. This implementation method uses flowing heat transfer oil to heat the cell stack 3 , the flowing heat-conducting oil enters the battery cell stack 3 after being heated in the heat-conducting oil heating device to heat the battery cell stack 3 . During the flow o...

specific Embodiment approach 1

[0044] Embodiment 1: The heat transfer oil heating device 4 adopts a serpentine flow field structure to ensure the residence time of the heat transfer oil in the heat transfer oil heating device 4 and achieve the effect of sufficient heat exchange. The heat transfer oil heating device 4 is heated by electric heating, and the heat transfer oil uses a heat transfer oil to drive a pump to promote the circulation of the heat transfer oil. The heat transfer oil with a lower temperature enters the heat transfer oil heating device 4 for heating under the drive of the driving pump, and the heated heat transfer oil enters the fuel cell stack 3 to heat the fuel cell stack 3 . The heat transfer oil that has fully exchanged heat in the fuel cell stack 3 and flows out of the fuel cell stack 3 enters the heat transfer oil heating device 4 again for heating under the drive of the heat transfer oil driving pump, thus forming a cycle and realizing the start-up of the fuel cell stack 3 The proc...

specific Embodiment approach 2

[0045] Specific implementation mode 2: The heat transfer oil heating device 4 adopts a parallel flow field structure, and the diameter of the flow channel is 1mm, so as to ensure that the heat transfer oil is heated evenly everywhere. The heat transfer oil heating device 4 uses the high-temperature tail gas of the reformer to heat it, and the heat transfer oil uses the heat transfer oil to drive the pump to promote the circulation of the heat transfer oil. The heat transfer oil with a lower temperature enters the heat transfer oil heating device 4 for heating under the drive of the driving pump, and the heated heat transfer oil enters the fuel cell stack 3 to heat the fuel cell stack 3 . The heat transfer oil that has fully exchanged heat in the fuel cell stack 3 and flows out of the fuel cell stack 3 enters the heat transfer oil heating device 4 again for heating under the drive of the heat transfer oil driving pump, thus forming a cycle and realizing the start-up of the fuel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com