Directional staged pyrolysis and carbonization method for sludge

A sludge carbon and sludge technology, which is applied in the field of graded directional pyrolysis sludge carbonization, can solve problems such as uneven heating, and achieve the effects of good physical and chemical properties and increased specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

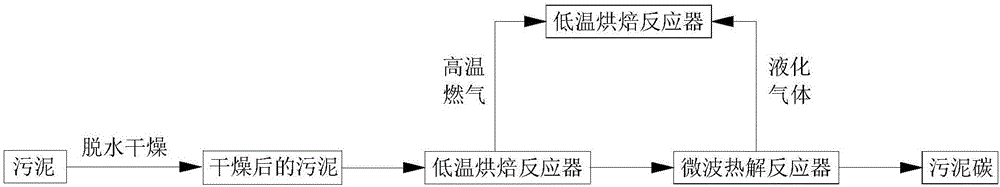

[0032] A method for grading and directional pyrolysis sludge carbonization, comprising the following steps:

[0033] (1) Dehydration and drying: the sludge is dehydrated to a sludge with a moisture content of 40% to 60%;

[0034] (2) Low-temperature baking: the sludge dehydrated and dried in step (1) is subjected to low-temperature baking treatment at 200° C. for 1 hour;

[0035] (3) Medium-temperature carbonization: the solid product obtained in the step (2) low-temperature baking treatment is heated to 500° C. by microwaves for 0.5 h of medium-temperature carbonization to obtain sludge carbon.

[0036] The dehydration and drying of the sludge in step (1) can be achieved by selecting a sludge dewatering machine or a mechanical dehydration device. Step (3) The liquid and gas products produced by microwave medium-temperature carbonization are burned by a burner to generate high-temperature flue gas, and the high-temperature flue gas passes through a low-temperature baking reac...

Embodiment 2

[0039] A method for grading and directional pyrolysis sludge carbonization, comprising the following steps:

[0040] (1) Dehydration and drying: the sludge is dehydrated to a sludge with a moisture content of 40% to 60%;

[0041] (2) Low-temperature baking: the sludge dehydrated and dried in step (1) is subjected to low-temperature baking treatment at 300° C. for 2 hours;

[0042] (3) Medium-temperature carbonization: the solid product obtained in the step (2) low-temperature baking treatment is heated to 600° C. by microwaves for 0.8 hours of medium-temperature carbonization to obtain sludge carbon.

[0043] The sludge carbon specific surface area produced by this example is 51.36m 2 / g, carbon content 16.75%.

Embodiment 3

[0045] A method for grading and directional pyrolysis sludge carbonization, comprising the following steps:

[0046] (1) Dehydration and drying: the sludge is dehydrated to a sludge with a moisture content of 40% to 60%;

[0047] (2) Low-temperature baking: the sludge dehydrated and dried in step (1) is subjected to low-temperature baking treatment at 350° C. for 3 hours;

[0048] (3) Medium-temperature carbonization: the solid product obtained in the step (2) low-temperature baking treatment is heated to 800° C. by microwave for 1 hour of medium-temperature carbonization to obtain sludge carbon.

[0049] The sludge carbon specific surface area produced by this example is 49.32m 2 / g, carbon content 17.02%.

[0050] Compared with the sludge carbon produced by the classification and directional pyrolysis sludge carbonization method proposed by the present invention and the sludge carbon obtained in the prior art, the sludge carbon obtained by the present invention has an enla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com