Oil gas slice mining method through in-situ heat injection in oil shale thick ore bed

A layered mining and oil shale technology, applied in the direction of mining fluid, earthwork drilling, wellbore/well components, etc., can solve problems such as uneven heating of thick ore layers, insufficient steam supply, and difficult oil and gas resources. Achieve the effect of solving insufficient steam supply, improving oil and gas recovery rate, and greater flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical scheme of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. Obviously, the described embodiments are only a part of the present invention. Other embodiments obtained below all belong to the protection scope of the present invention.

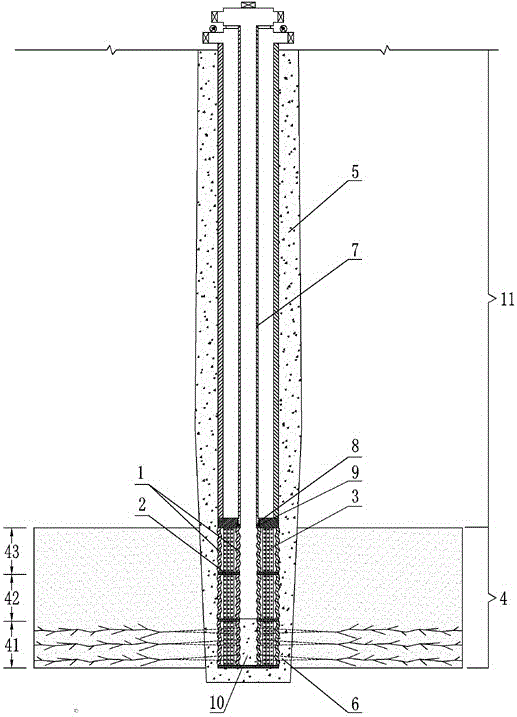

[0020] Such as figure 1 As shown, the thick oil shale target thermal injection mining area is selected, a near-horizontal single oil shale layer with a thickness of 60 m and a buried depth of 11 is 160 m. Sections are respectively the subsection 41 under the ore seam, the subsection 42 in the ore seam and the subsection 43 on the ore seam.

[0021] A method for extracting oil and gas by in-situ heat injection layering in thick oil shale beds, the specific steps are as follows:

[0022] ① First connect several vacuum bellows 1 with annular blind plate 2, and wrap multi-layer heat insulation material 3 in the annular gap between the two sets of metal bellows, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com