Formation aging method for inhibiting gas expansion of lithium titanate battery

A lithium titanate battery and flatulence technology, which is applied in the direction of non-aqueous electrolyte battery, electrolyte battery manufacturing, climate sustainability, etc., can solve the problems of inability to adapt to the industrialization of lithium titanate battery, high process equipment requirements, and increased production costs , to achieve obvious effects of inhibiting gas production, improving cycle performance, and reducing time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

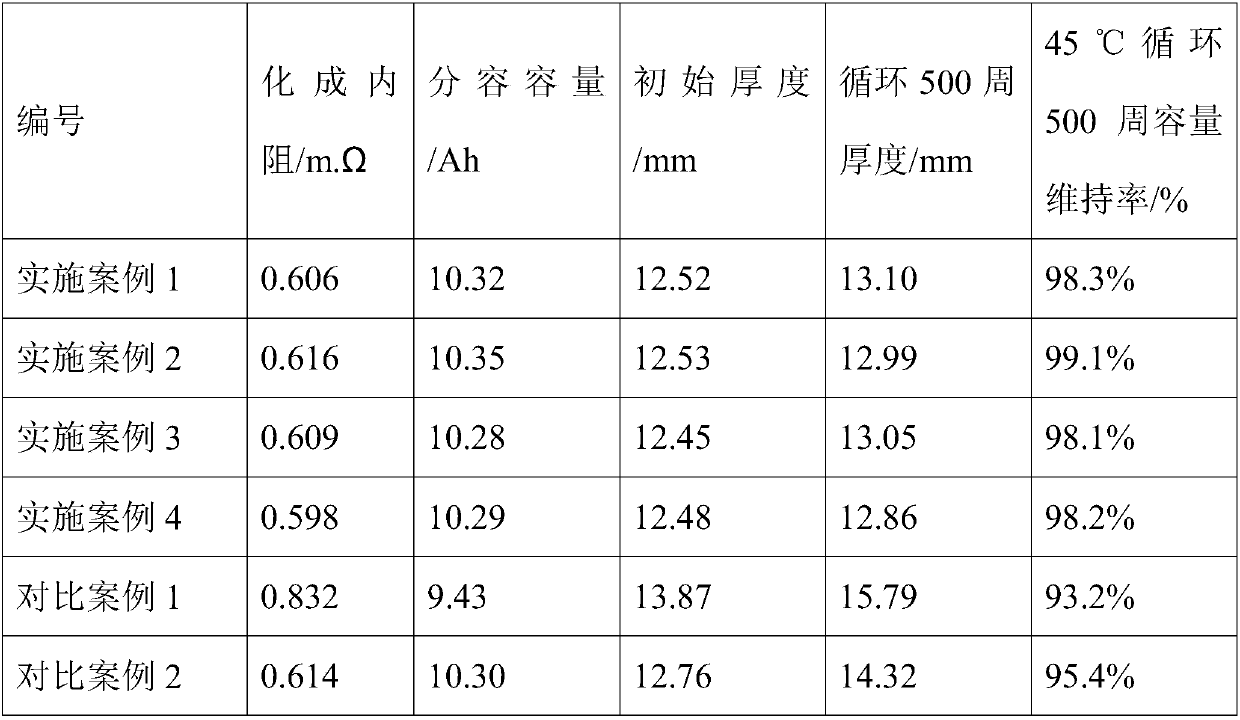

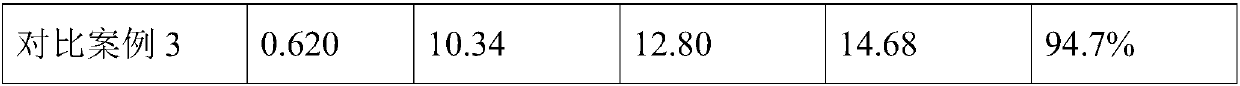

Embodiment 1

[0027] A chemical aging method for inhibiting flatulence of lithium titanate batteries. After liquid injection, the NCM / LTO battery is placed at 25°C for 24 hours, and charged to 2.6V with a constant current of 1.0C; transferred to a constant current of 0.2C Charge to 2.85V; place the battery in the open state at 55°C, -0.095Mpa, and age at -55°C dew point for 72h, and then discharge it to 2.4V with a constant current of 1C; then place it at -20°C, -0.095Mpa, -55 Aging at ℃ dew point for 12h, sealing after the end; separate volume.

Embodiment 2

[0029] A chemical aging method for inhibiting flatulence of lithium titanate batteries. After liquid injection, the NCM / LTO battery is placed at 25°C for 24 hours, and charged to 2.6V with a constant current of 1.0C; transferred to a constant current of 0.2C Charge to 2.85V; put the battery in the open state at 55°C, -0.095Mpa, and age at -55°C dew point for 72h, and then discharge it to 2.4V with a constant current of 1C; then put it at -10°C, -0.095Mpa, -55 Aging at ℃ dew point for 12h, sealing; separate volume.

Embodiment 3

[0031] A chemical aging method for inhibiting the flatulence of lithium titanate batteries. After liquid injection, the NCM / LTO battery is placed at 45°C for 24 hours, charged with a constant current of 1.0C to 2.6V; transferred to a constant current of 0.1C Charge to 2.85V; put the battery in the open state at 45°C, -0.095Mpa, -55°C dew point for aging for 24h, and then use 1C constant current discharge to 2.4V; then put it at -20°C, -0.095Mpa, -55 Aging at ℃ dew point for 12h, sealing; separate volume.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com