Feeding trolley of electric machine stator winding paint-dipping system

A motor stator and winding technology, applied in the direction of electric components, manufacturing motor generators, electrical components, etc., can solve the problems of occupying a large production space, achieve the effects of improving work efficiency, reducing labor costs, and saving production time and costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

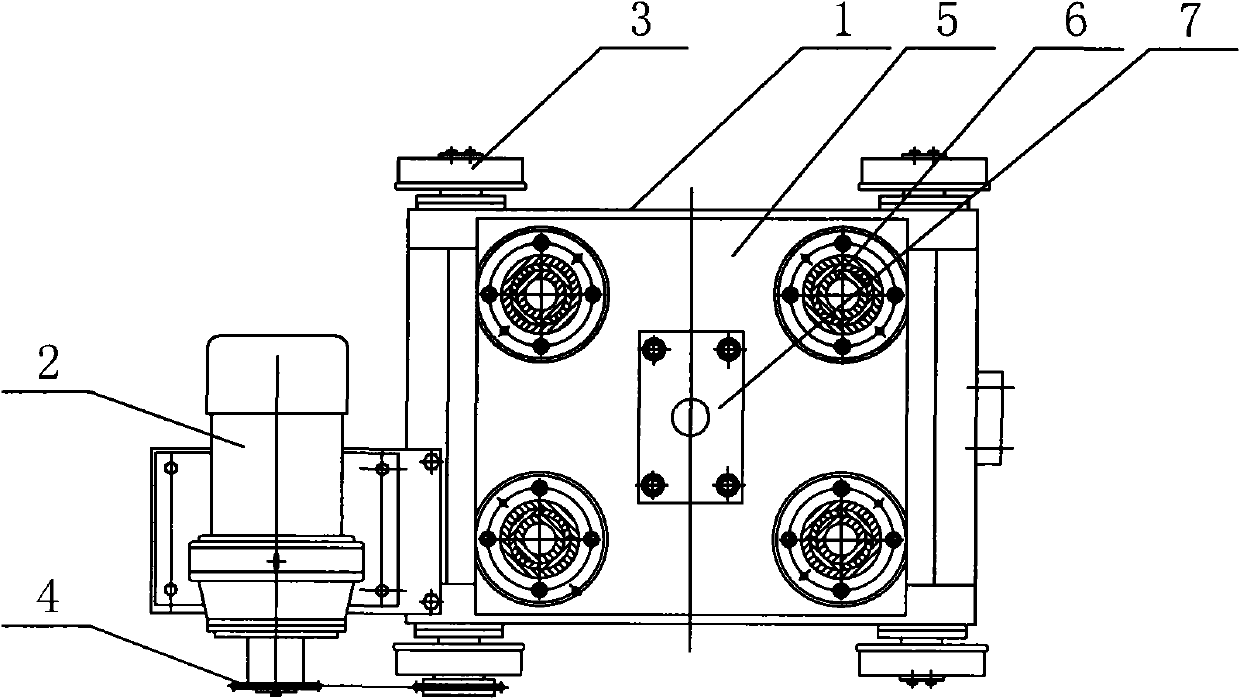

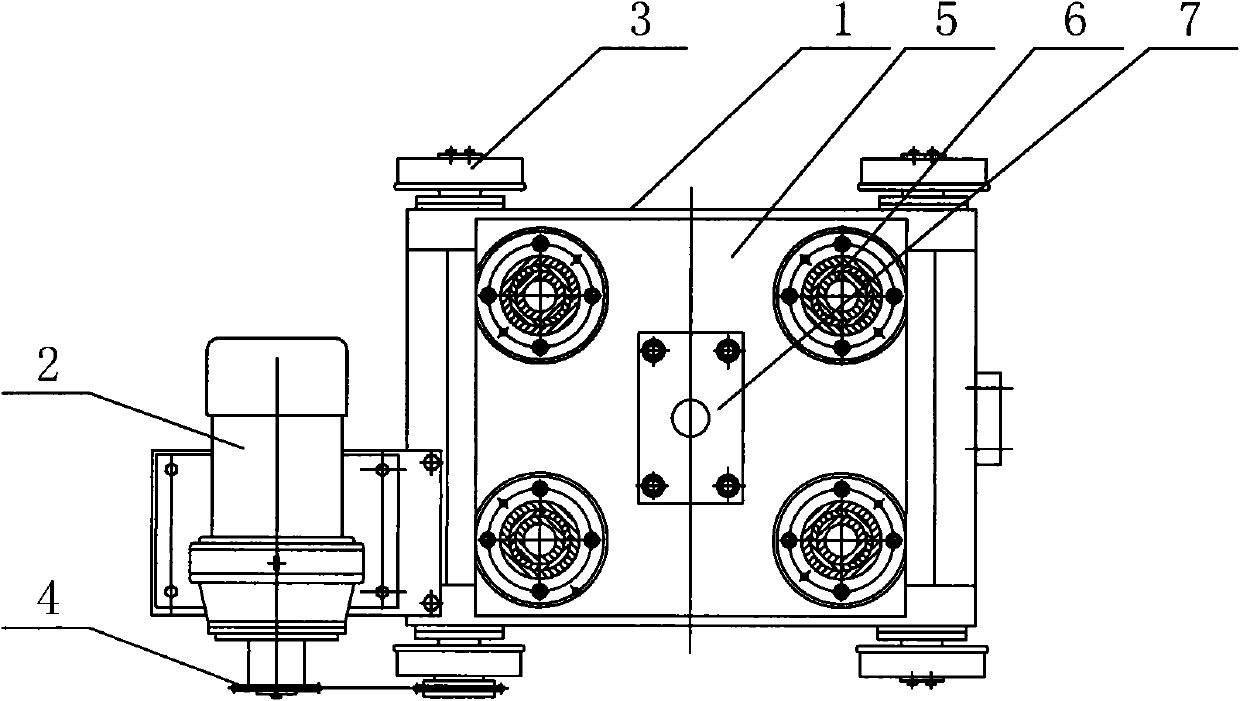

[0009] Such as figure 1 As shown, the feeding trolley of the motor stator winding dipping system includes a feeding trolley body 1, a motor 2 is fixed on the car body 1, two pairs of track wheels 3 are arranged on the lower part of the car body 1, and the motor 2 is driven by a pulley 4 Rail wheel 3 runs; Lifting plate 5 is installed on car body 1, is connected by four sliding posts 6 between described lifting plate 5 and car body 1, and described sliding post 6 is installed on the lower surface of lifting plate 5, and sliding post 6 is inserted into the sliding column hole provided on the car body 1; the lower surface of the center of the lifting plate 5 is supported on the pole of the hydraulic cylinder 7, and the hydraulic cylinder 7 is fixed on the car body 1 and moves together with the car body 1.

[0010] The invention is a material loading trolley of the motor stator winding dipping system, which can make the motor stator winding be loaded and unloaded smoothly during t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com