Intelligent beer saccharifying tank and production method thereof

A saccharification tank and intelligent technology, applied in the field of intelligent beer saccharification tanks, can solve the problems of centralized monitoring and management of equipment, restrictions on the development of small breweries, untimely and incomplete measurement, etc., to save filtration time, ensure beer quality, and increase production and sales Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

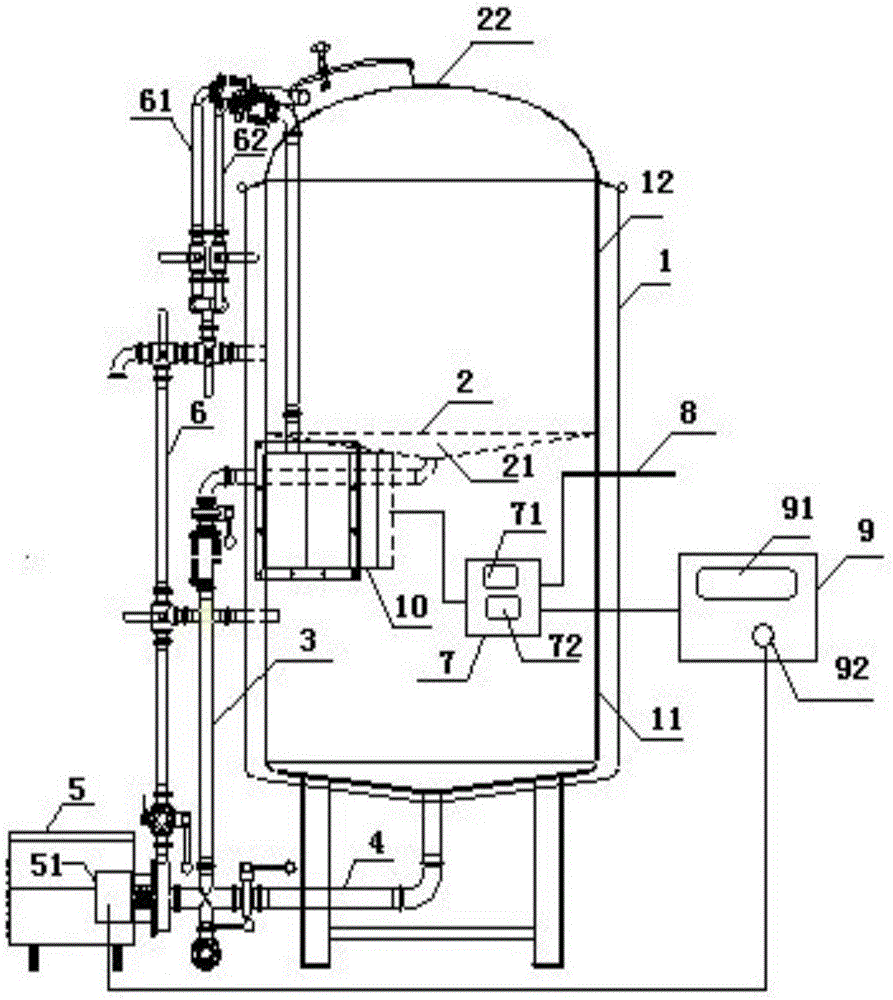

[0025] Such as figure 1 As shown, the present invention provides an intelligent beer saccharification tank, comprising a tank body 1, the tank body 1 is composed of a saccharification chamber 11 and a filter chamber 12, a filter plate 2 is arranged at the bottom of the filter chamber 12, and the filter plate 2 The wort outflow pipeline 3 is connected to the water inlet pipeline 4 through its bottom groove, and the curved surface of the groove 21 is conical or arc-shaped. One end of the water inlet pipeline 4 is connected to a water pump 5, and the other end is connected to the saccharification chamber 11; the water pump 5 is connected to the main wort filtration pipeline 6 through a frequency converter 51 arranged inside it, and the wort filtration One of the outlet ends of the main pipeline 6 is connected to the filter chamber 12 through the turbid wort ret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com