Mode locking system for fine-blanking machine

A technology of fine blanking machine and mold clamping, which is applied in metal processing equipment, forming tools, manufacturing tools, etc. It can solve the problems of frequent mold replacement, low safety factor, loose screws, etc., and achieves low mechanism cost, simple installation form, and reduced The effect of production time cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

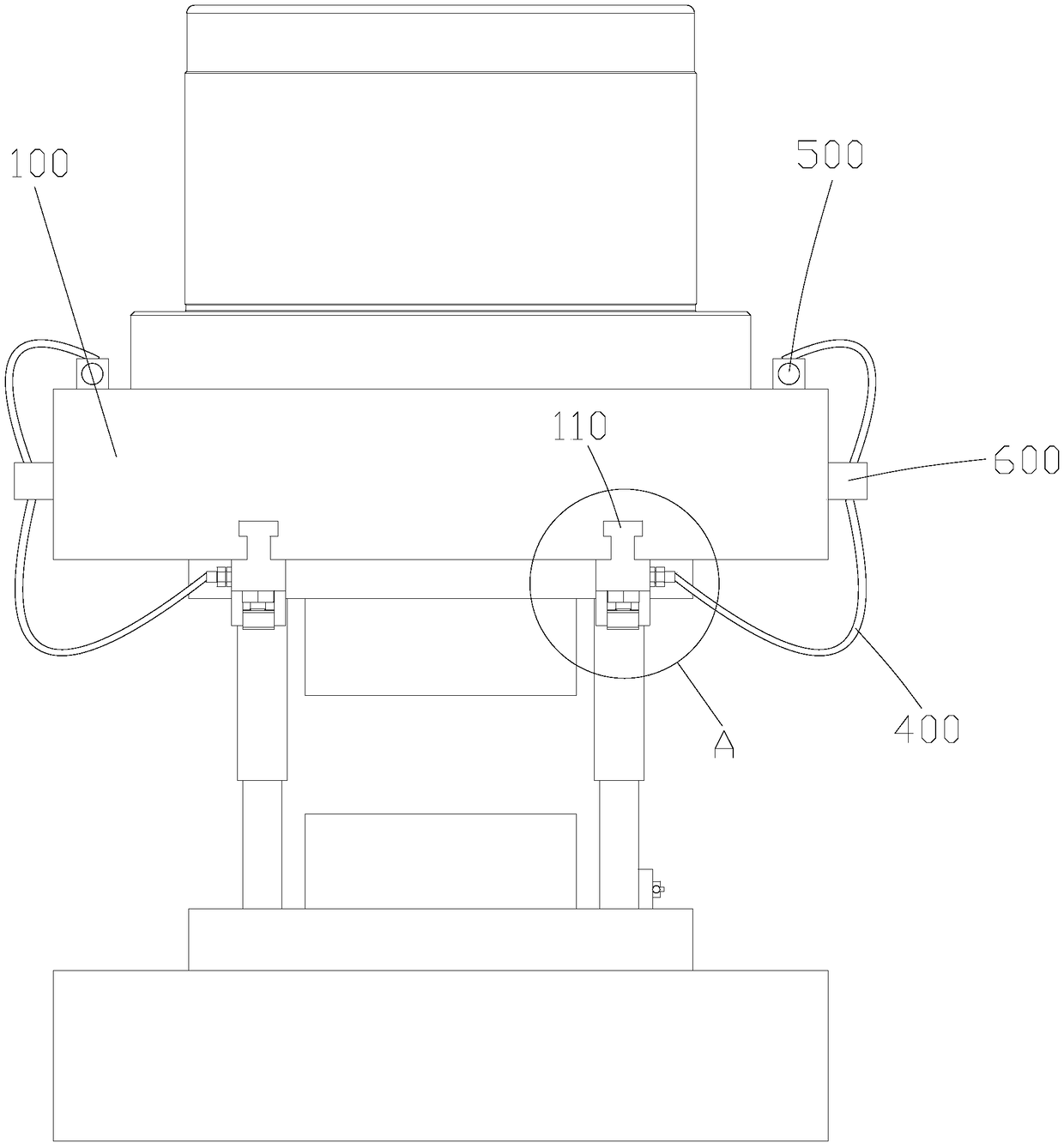

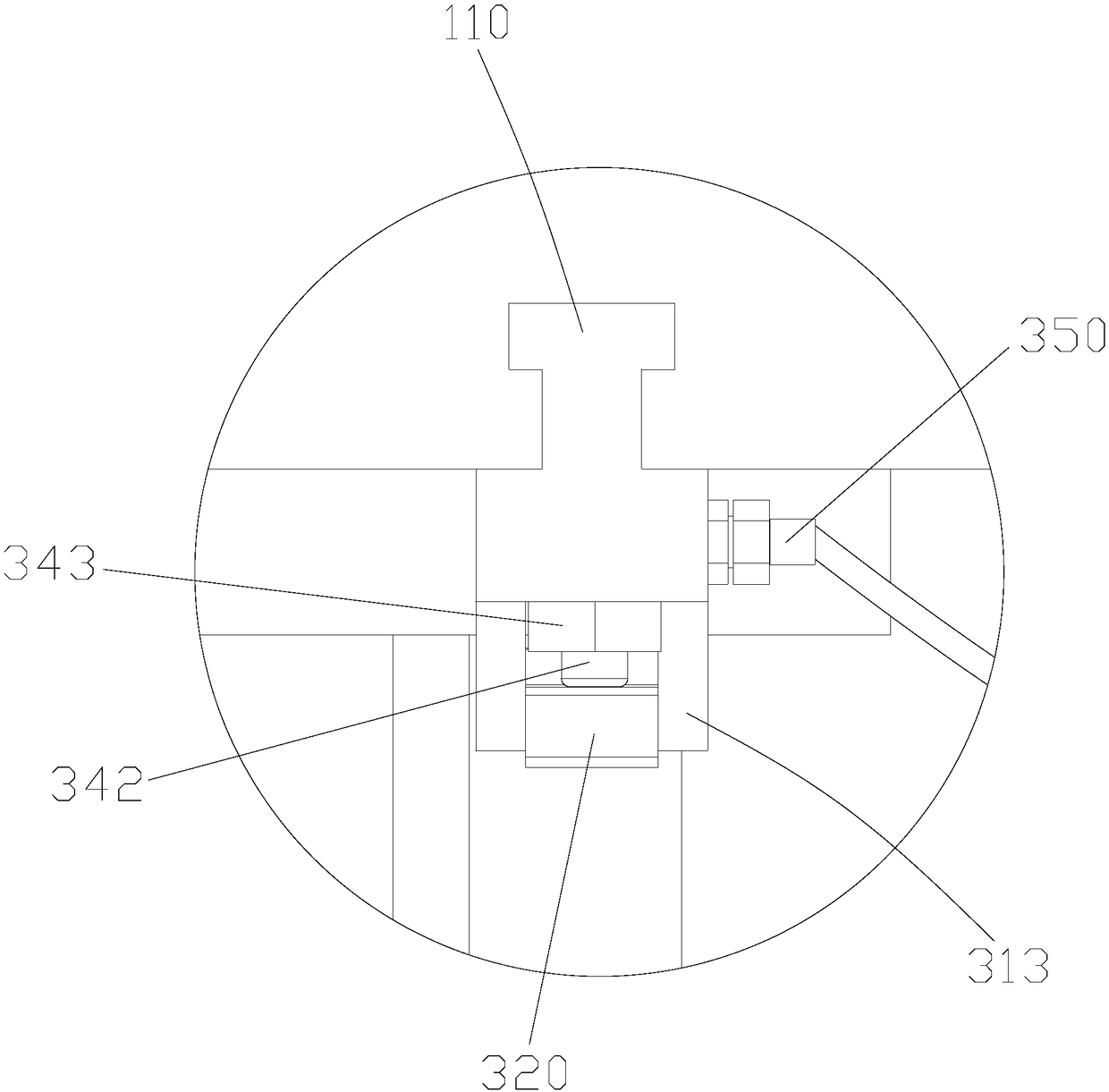

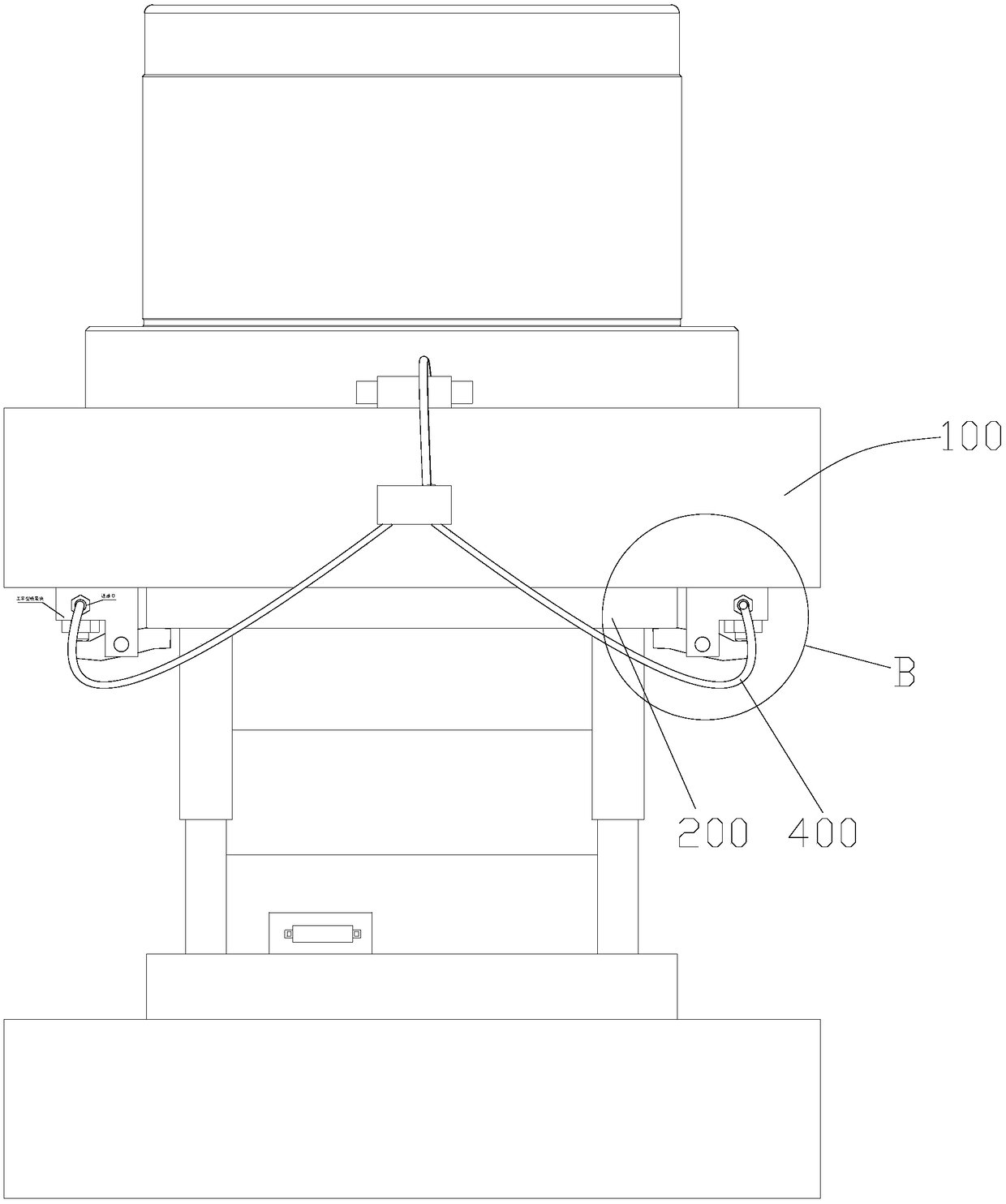

[0026] Such as Figure 1-7 Shown is a fine blanking machine mold clamping system of a preferred embodiment of the present invention, including a mold clamping device 300, which includes a locking block 310, a lock tongue 320, a rotating shaft 330, an embedded oil cylinder 340 and hydraulic hoses The joint 350; the locking block 310 includes an integrally formed body 311, a slider 312 and a support plate 313, the slider 312 is arranged on the top of the body 311, and the lower surface of the upper table 100 of the fine blanking machine is provided with a chute 110, and the slider The shape and size of 312 are adapted to the chute 110 so that the slider 312 can slide in the chute 110, and the installation position of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com