Vacuum pressure paint dipping cluster equipment with improved drying device

A technology of vacuum pressure dipping and clustering, which is applied to the device for coating liquid on the surface, pretreatment surface, coating, etc., can solve the problems of low dipping efficiency and discontinuous process links, and save production time and cost. , The effect of reducing labor costs and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

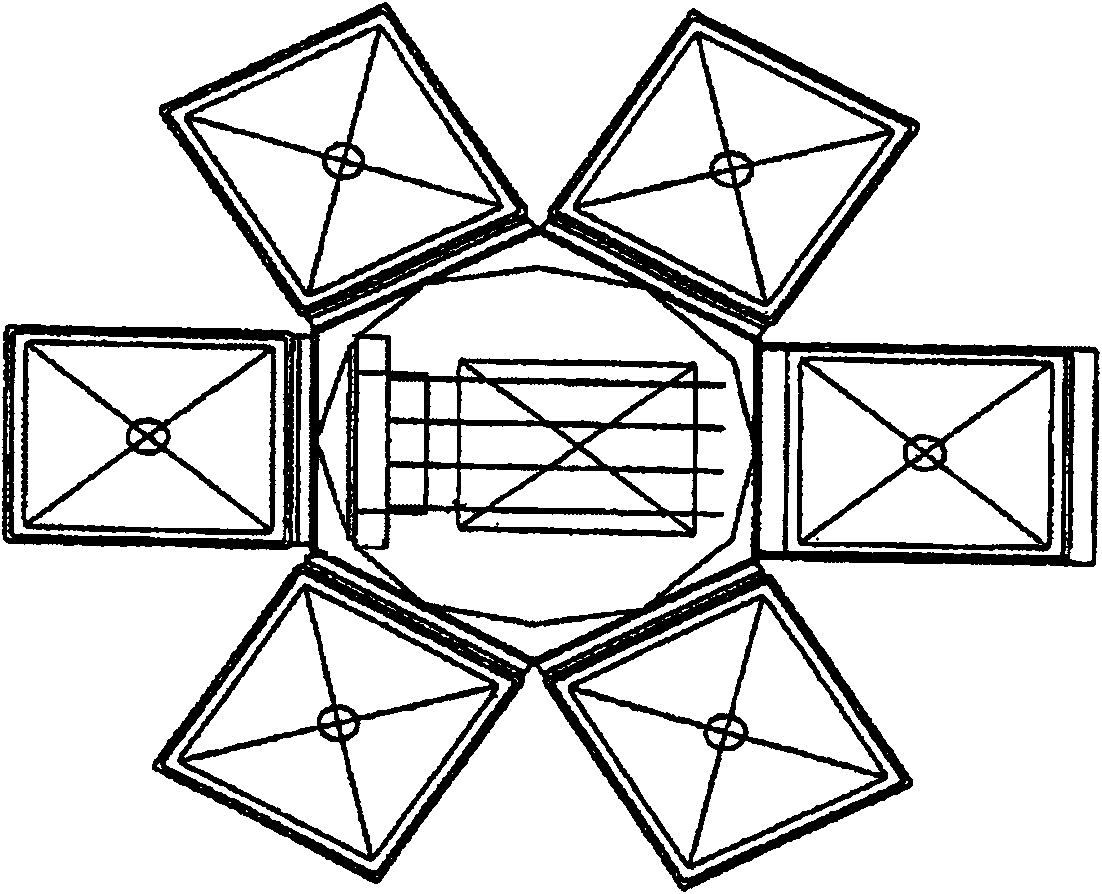

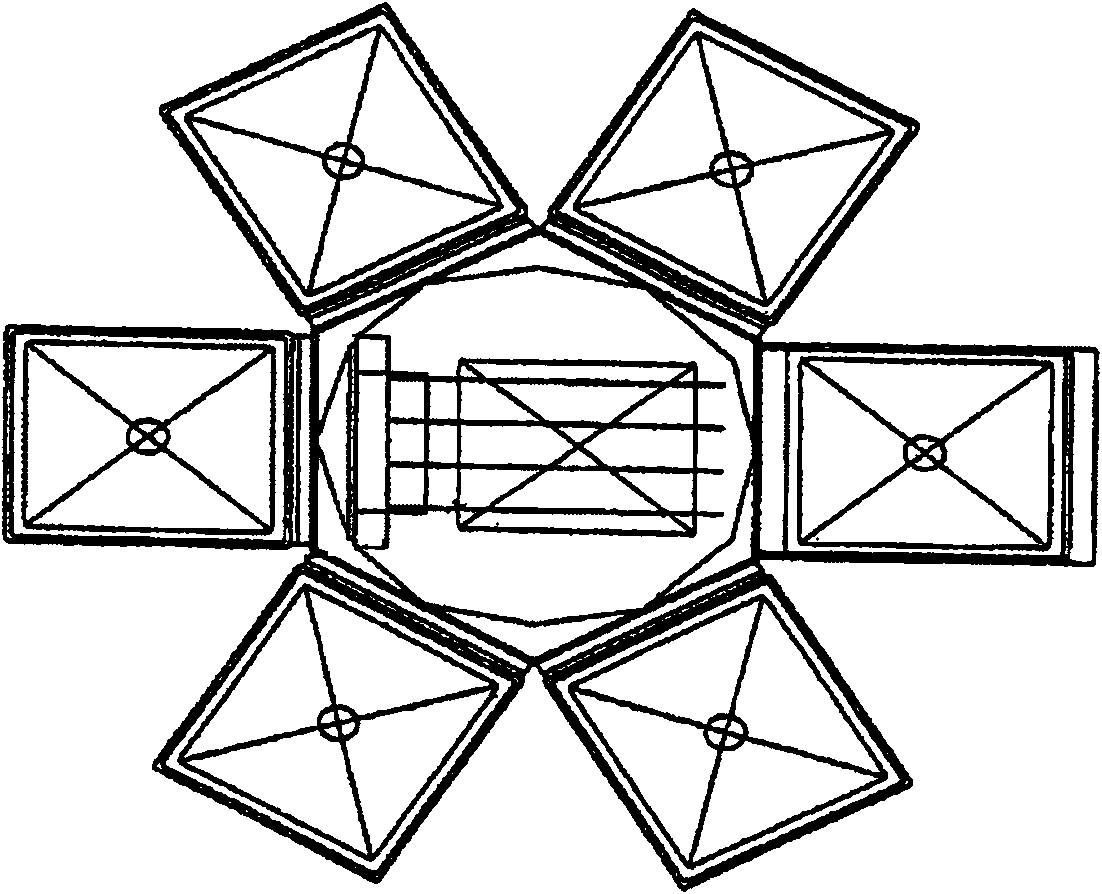

[0023] Such as figure 1 Shown, the present invention provides input and output room, is used for inputting the workpiece to be processed and the workpiece of output processing; Preheating studio, is used for drying and removing the moisture of workpiece surface and interior; It is used to impregnate the paint on the surface of the workpiece; the leveling studio is used to volatilize a part of the solvent, so that the surface of the coating film is in the surface drying stage; the drying studio is used to dry the workpiece after dipping paint, so that the coating film is in a semi-dry state State; curing studio, used for the final curing process of the dried paint; shared vacuum control room, used to realize the preheating room, paint storage room, dipping room, leveling room, drying room and curing The vacuum degree control of the chamber; the transportation device is located in the shared vacuum control room and has a bearing surface, which can transport the bearing surface t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com