Preparation method of cover sealing glue layer

A manufacturing method and sealant technology, which is applied in the field of can lid sealant layer manufacturing, can solve the problems of slow processing speed, long time-consuming, harmful to human body, etc., and achieve the effect of reducing processing time cost and saving glue injection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

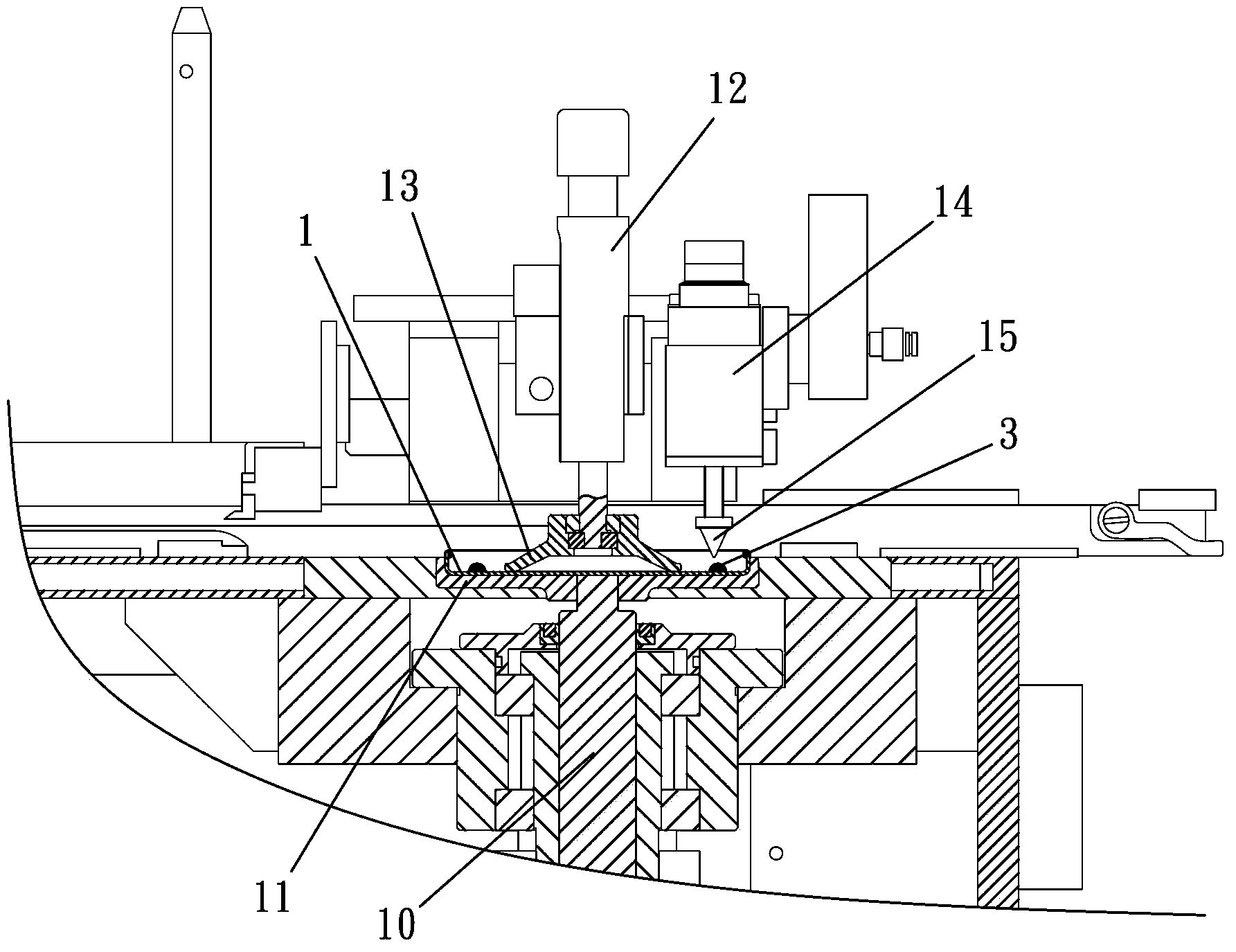

[0038] See Figure 5 , 6 , 7, 8, 9, when the glue injection mechanism 30 once injects the glue, inject a plurality of glue 7 on the inner surface periphery of the tank cover 6 at the same time ( Figure 8 shown), and use the molding mechanism 20 to press the granular rubber material 7 into an annular rubber layer 8 ( Figure 9 shown); its injection mechanism 30 ( Figure 8 Shown) be set as a circular swivel seat 36 with a plurality of elevating rods 37, each elevating rod 37 has a positioning plate 38 for the fixed tank cover 6, and, corresponding to the side of the elevating rod 37, the positioning plate 38 is provided with The positioning seat 31, the positioning seat 31 is set with a glue injection nozzle 32 and a conduit 33, the conduit 33 is provided with a distribution tray 34, the distribution tray 34 has a plurality of discharge holes 35 and corresponds to the top of the positioning disk 38, through the injection nozzle 32 , conduit 33, material distribution tray 34...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com