Motor drying station of motor stator winding paint dipping system

A motor stator and winding technology, which is applied in the direction of electric components, manufacturing motor generators, electrical components, etc., can solve the problems of occupying a large production space, and achieve the effects of improving work efficiency, saving production time and cost, and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

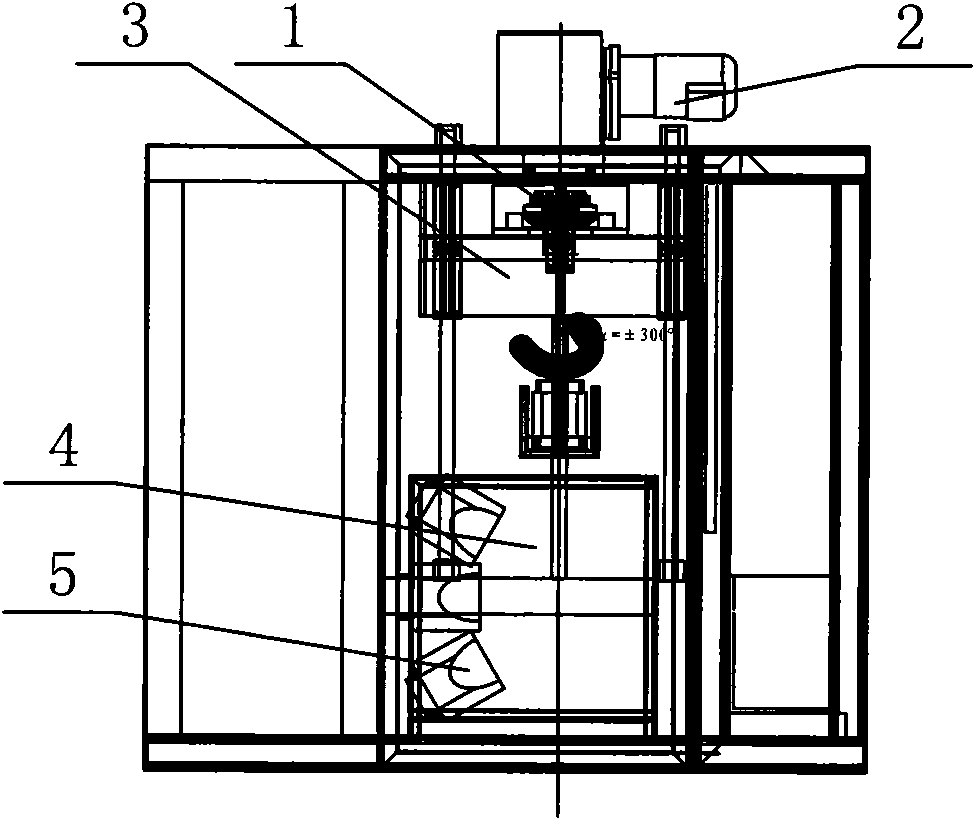

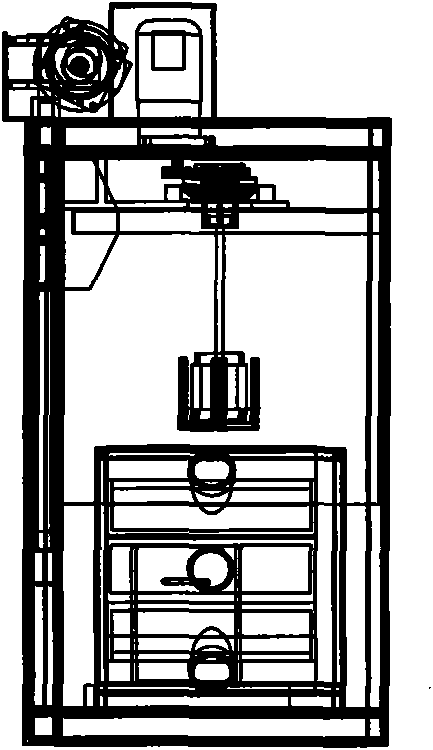

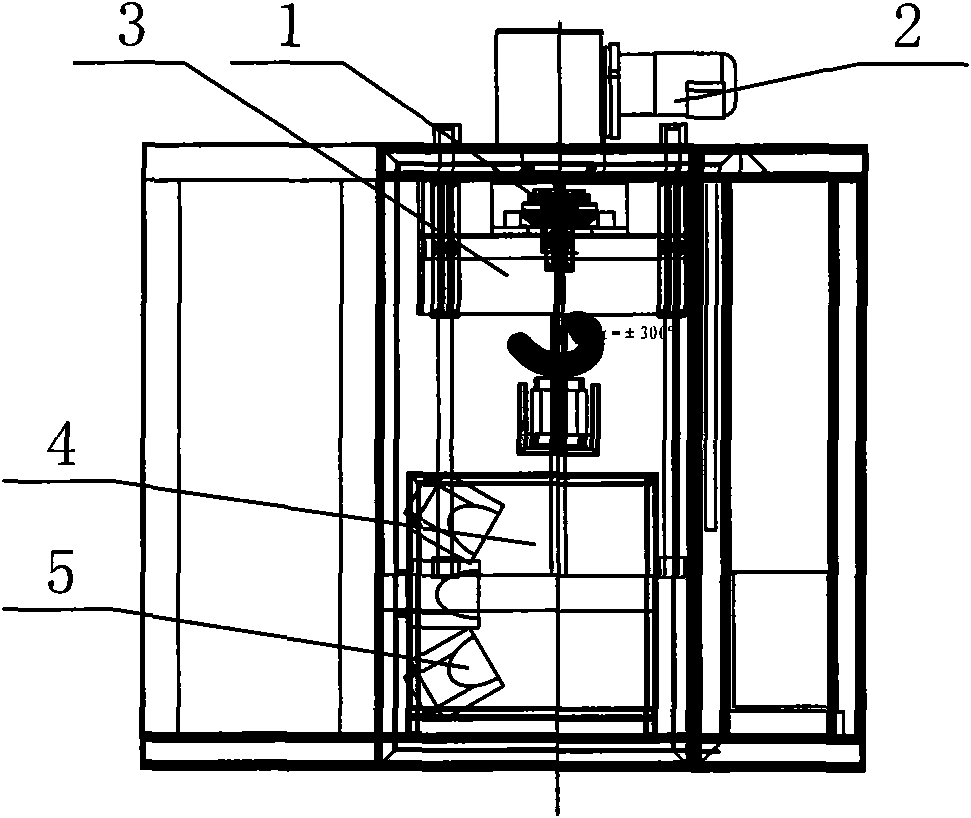

[0010] Such as Figure 1-2 As shown, the motor drying station of the motor stator winding paint dipping system includes a rotating mechanism 1, which is driven by the motor 2. The lower part of the rotating mechanism 1 is connected to the lifting mechanism 3, and the rotating mechanism 1 drives the lifting mechanism 3 to move up and down. Corresponding to the lower part of the lifting mechanism 3, a UV lamp box 4 is arranged, and several UV lamps 5 are arranged inside the UV lamp box 4.

[0011] The invention is a motor drying station of a motor stator winding paint dipping system. The motor drives a rotating mechanism and a lifting mechanism to operate, and sends the motor stator winding to a UV light box for drying. The motor stator winding impregnation system can solve the problem that a single product is idle between the two process links, which in turn leads to the problem that the storage and stacking of unfinished products will occupy a large production space. It can ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com