Induction shape correcting and die quenching and tempering technological method and equipment for annular parts

A technology of induction hardening and ring parts, applied in the direction of quenching agent, quenching device, heat treatment equipment, etc., can solve the problems of inner hole strain on the surface of the mandrel, unreliable control, high labor intensity, etc., and achieve compact structure, No smoke pollution, high electrothermal conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

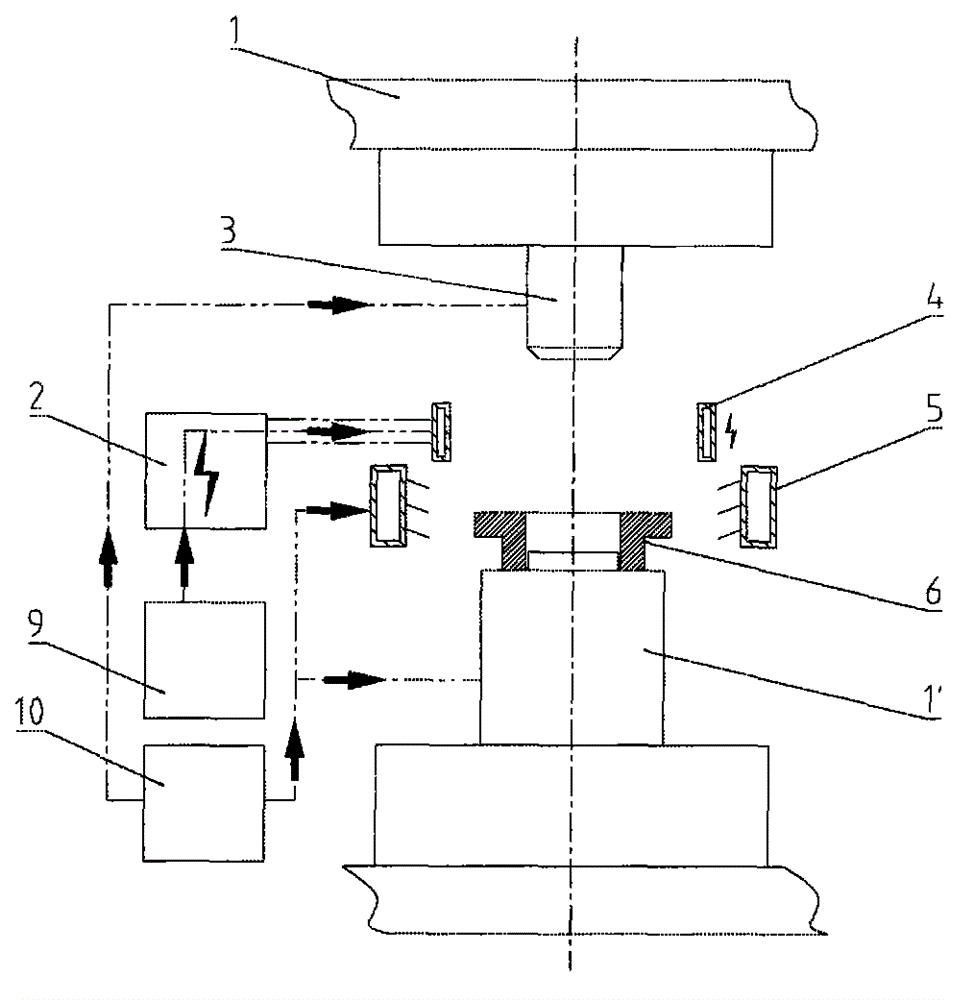

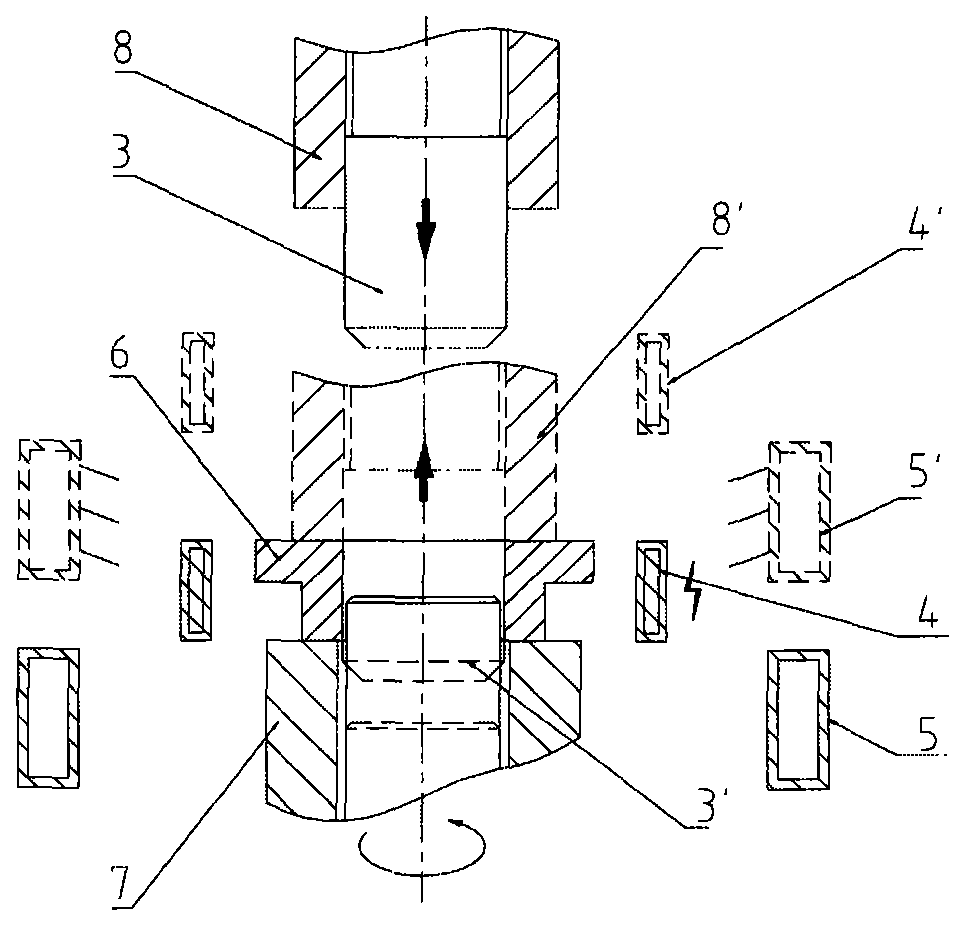

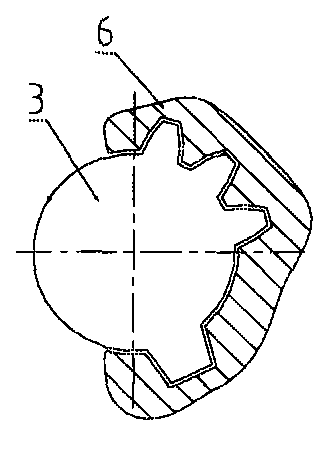

[0024] The invention relates to a process method and equipment for induction orthopedic mold press quenching and tempering of ring parts. The method includes feeding workpiece 6, heating with inductor 4, correcting core mold 3, upper pressing mold 8, and lower supporting mold 7 for press quenching , workpiece 6 with mandrel 3 induction tempering, mandrel 3 leaving, workpiece 6 unloading and other steps.

[0025] The equipment of the present invention includes an induction heating power supply 2 , a quenching machine tool 1 , cooling water 9 , and a quenching liquid circulation device 10 for implementing the entire process. Wherein the heating inductor 4, the external quenching liquid injection box 5, the upper die 8, the lower support die 7, the mandrel 3 and other components and their moving actuators and workpiece clamping mechanisms are installed on the frame of the quenching machine tool 1. The induction heating power supply 2, the cooling water 9, and the quenching liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com